Full-automatic high-speed punching machine

A punching machine, fully automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of inaccurate positioning, high noise of loading and unloading, low running speed, etc. Smooth and fast movement, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

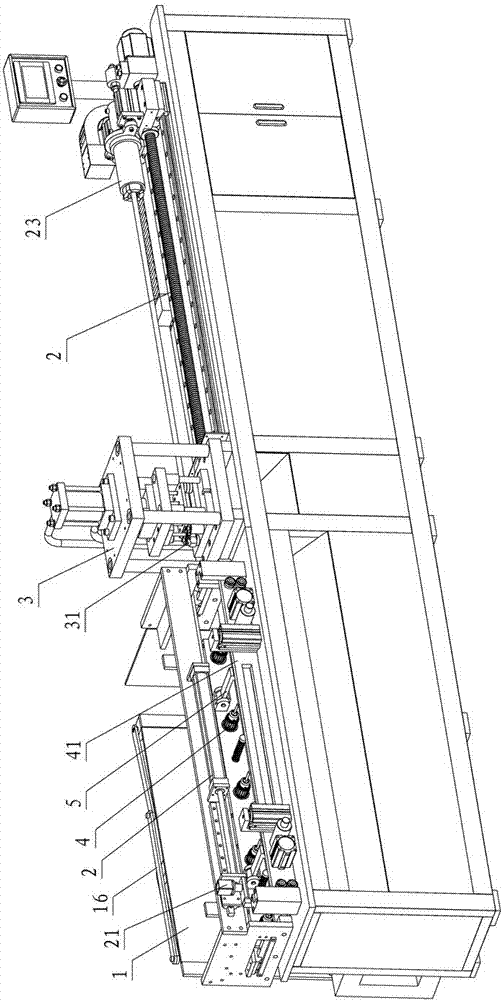

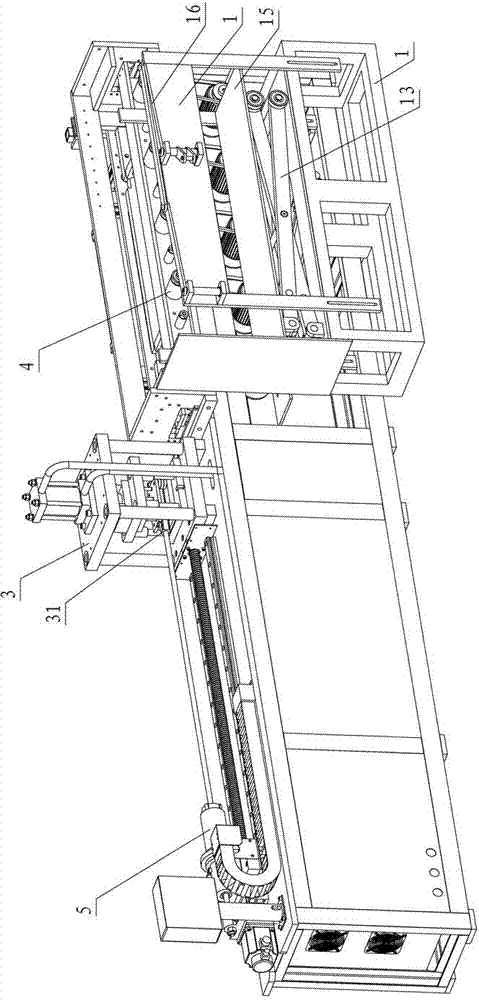

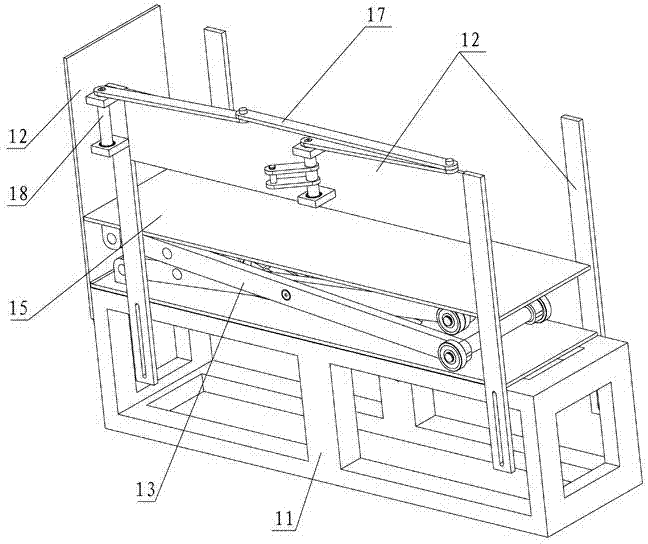

[0041] Such as figure 1 , 2 As shown, a fully automatic high-speed punching machine includes a frame, and the frame is provided with:

[0042] The feeding device 1 for placing pipes is located on one side of the frame and is a relatively independent device. There is no fixed connection with the frame, and the feeding device only needs to be close to the front half of the frame , so that the pipe can fall on the rack and proceed to the next step;

[0043] A traction device 2 for moving the pipe, which extends from the front end of the frame to the rear end of the frame, and can push the pipe;

[0044] A vertical punching device 3 for drilling vertical holes, the vertical punching device 31 is located in the middle of the frame, and the traction device 2 drives the pipe to shuttle back and forth in the vertical punching device 3;

[0045] A horizontal punching device 4 for punching and drilling transverse holes, the horizontal punching device 4 is located in the front half of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com