Helicopter wheel undercarriage sled

A landing gear, helicopter technology, applied in the direction of sleds/skis, etc., can solve problems such as restrictions, and achieve the effect of increasing the ground contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

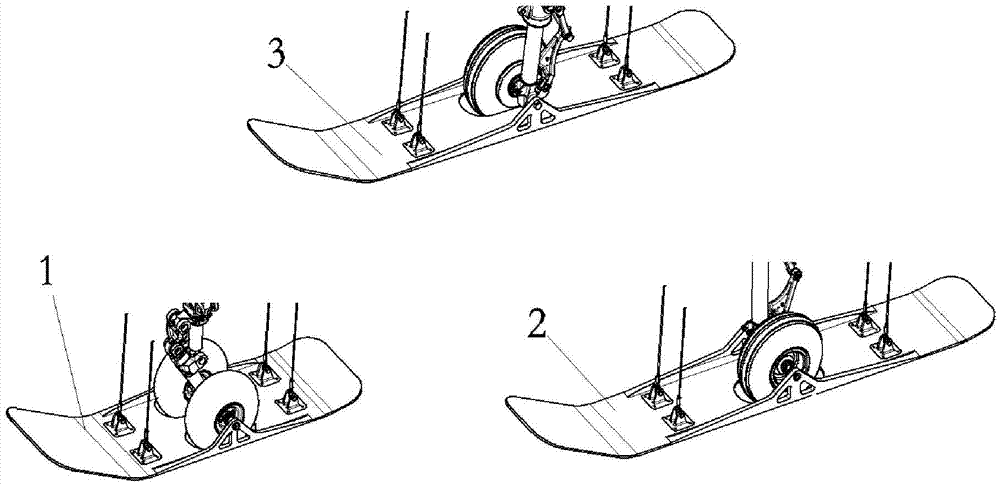

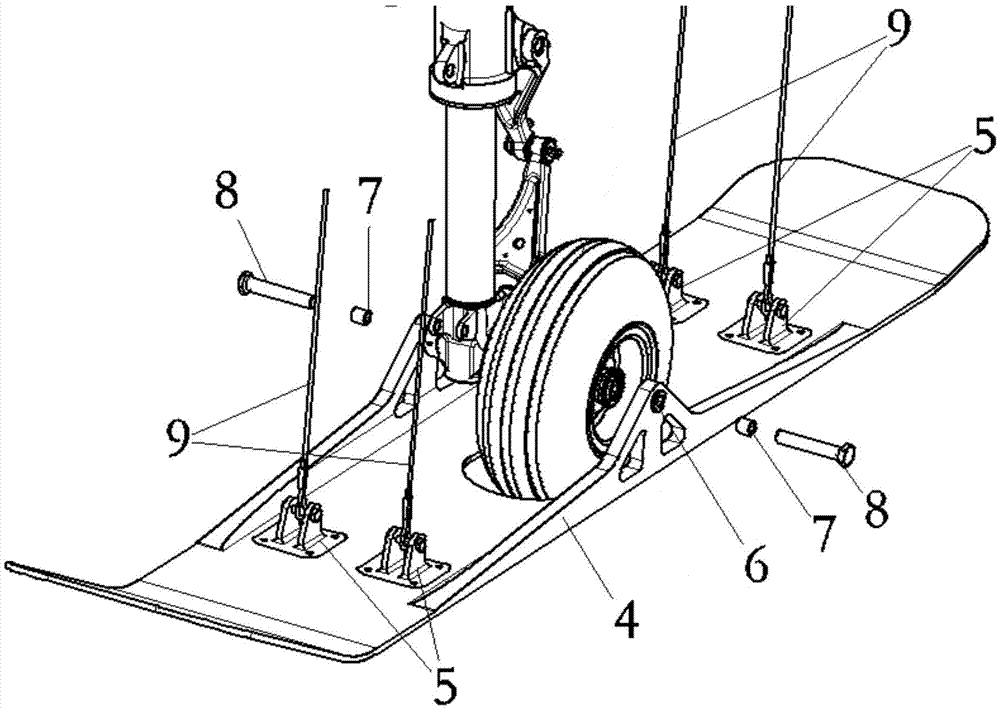

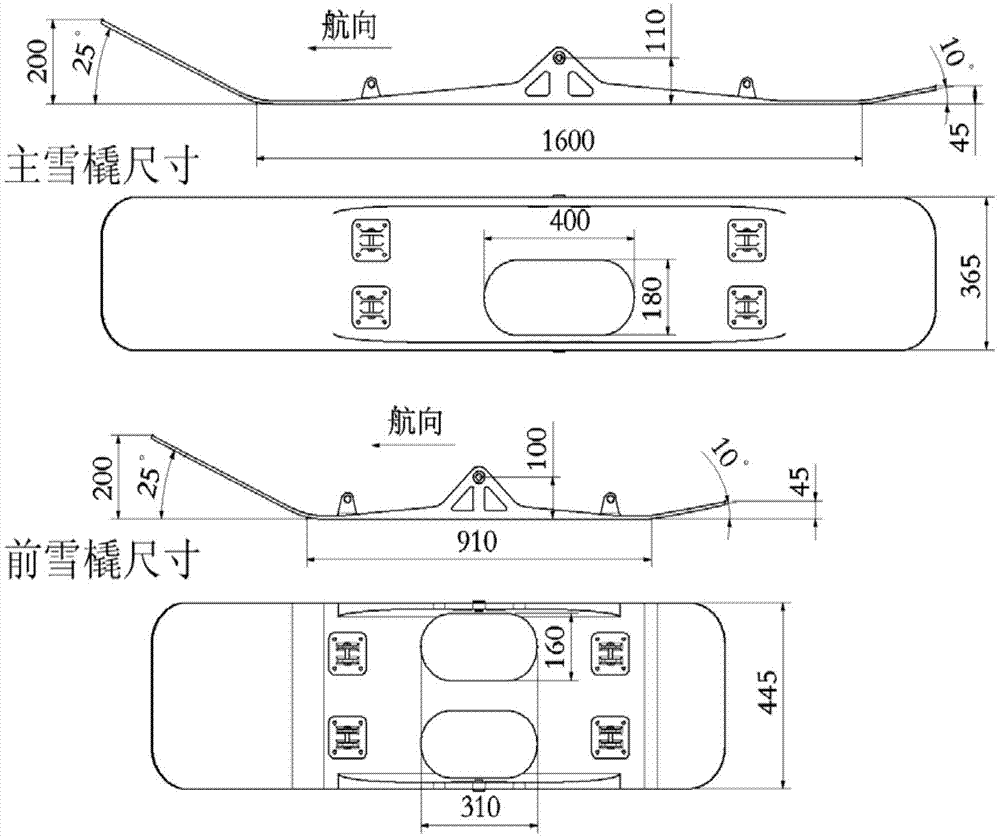

[0009] A helicopter wheeled landing gear sled, such as figure 1 , 2 , 3, including skid plate 4, bushing 7, threaded shaft 8, rubber buffer rope 9, wherein, skid plate 4 is installed on the axle of landing gear through bushing 7, threaded shaft 8, and can rotate freely, 4 One end of root rubber buffer rope 9 is connected on the joint 5 of skid plate 4, and the other end is connected on the joint of fuselage, and liner 6 is pre-embedded on skid plate 4.

[0010] The reaction point of the snow on the sled basically passes through the installation shaft. On the wheel shaft of the landing gear there is a screw thread matched with the threaded shaft 8, the sledge is hinged to the wheel shaft by the threaded shaft 8, and before the buffer rope 9 is connected, the sledge rotates unconstrained. The front and rear joints of the sled 4 are respectively connected to the joints on the fuselage by two rubber buffer ropes. When the helicopter is flying, the sled can maintain a certain ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com