Evaporating device

A technology of evaporation and evaporation source, which is applied in the direction of vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of long transmission and vacuuming time, complicated equipment, etc., and save vacuuming time, save The effect of teleportation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

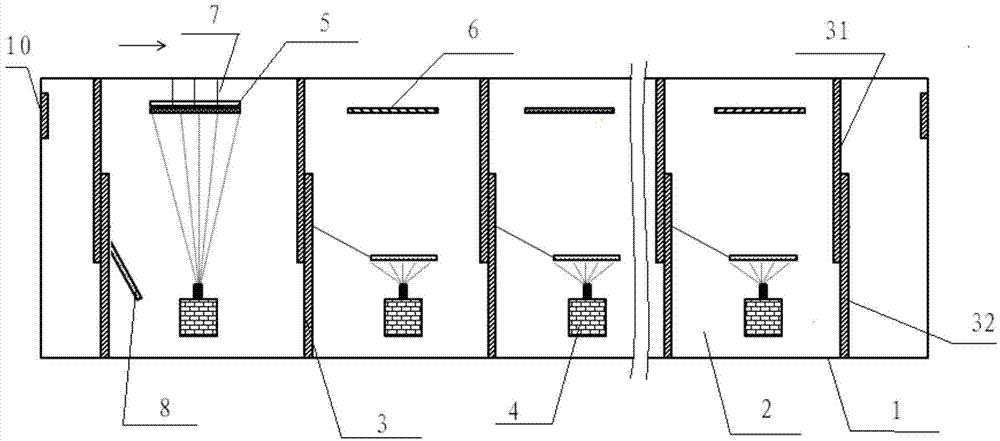

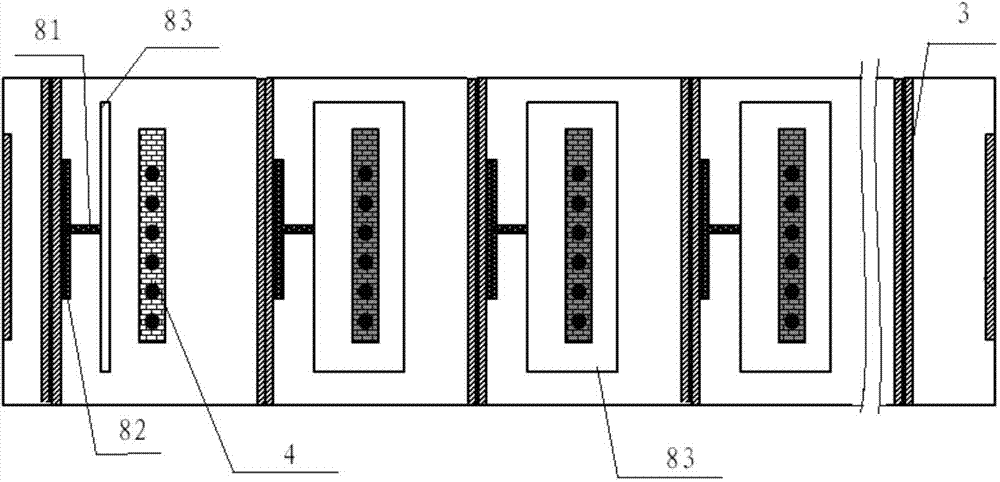

[0031] Such as Figure 1-8 As shown, this embodiment provides an evaporation device, including an evaporation chamber 1 for evaporating a substrate 11 to be evaporated, and the evaporation chamber 1 includes: a plurality of evaporation sub-chambers 2, and An isolation unit 3 located between adjacent evaporation sub-chambers 2 that can isolate adjacent evaporation sub-chambers 2, each of the evaporation sub-chambers 2 includes Evaporation source 4 at one end;

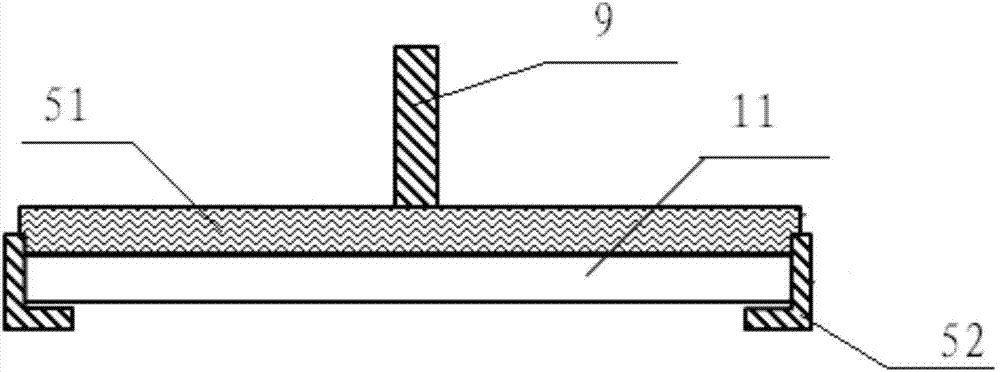

[0032] And a transfer unit 5 which is arranged opposite to the evaporation source 4 and carries the substrate to be evaporated 11 to move between the evaporation sub-chambers 2 .

[0033] The evaporation device of this embodiment includes a plurality of evaporation sub-chambers, the substrate to be evaporated is moved in the plurality of evaporation sub-chambers to complete the evaporation of each layer, saving the transfer time of the substrate to be evaporated, and the evaporation chamber The chamber is maintained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com