Testing system simulating ultimate dynamic bearing capacity of cyclic load lower plate anchor

A technology for simulating cycles and testing systems, which is applied in basic structure tests, buildings, and basic structure engineering. The failure process of the surrounding soil cannot be directly observed, etc., to achieve a reasonable evaluation of the ultimate bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

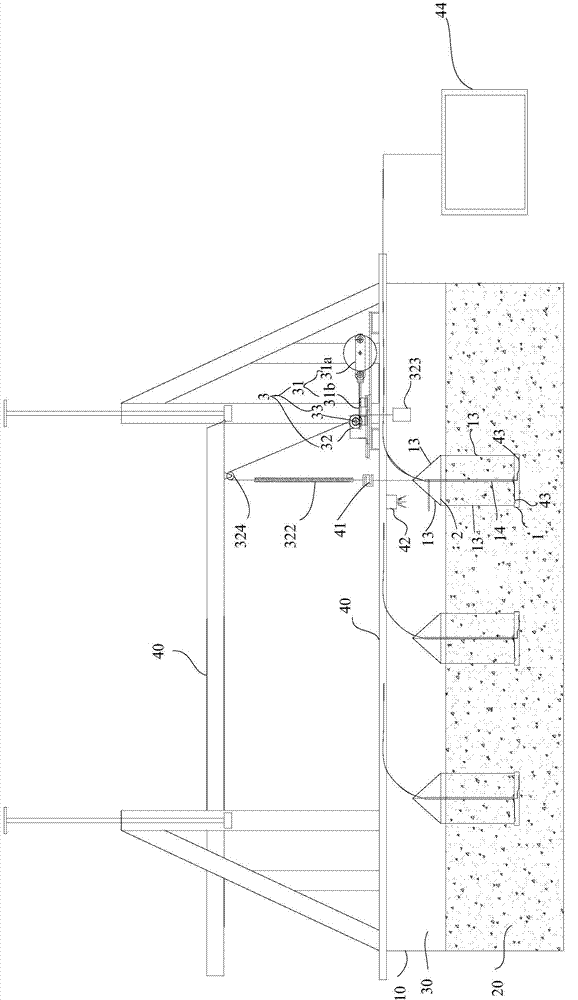

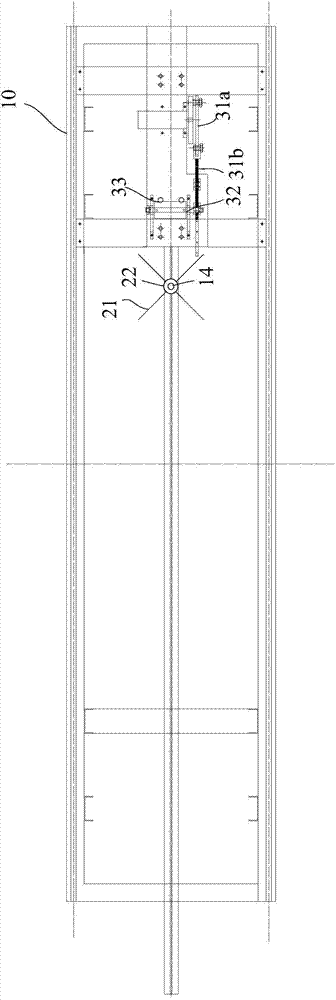

[0047] Such as Figure 1-9 As shown, the embodiment of the present invention provides a test system for simulating the ultimate dynamic bearing capacity of a plate anchor under cyclic loads, including: a plate anchor model 1, a cross support for limiting the anchor shin of the plate anchor model to move perpendicular to the bed surface Frame 2, cyclic load loading device 3 and measuring device;

[0048] see Figure 5-9 , plate anchor model 1, comprising an upper panel 11, a lower panel 12, and an anchor shank 13, wherein the upper panel 11 and the lower panel 12 are detachably connected; the upper panel 11 and the lower panel 12 are buried under the bed surface 20;

[0049] see figure 1 , figure 2 , used to define the plate anchor model as a cross support frame 2 that moves perpendicular to the bed surface 20, fixed on the soil tank 10, and the anchor shin 13 connects the upper panel 11 and the cross support frame 2;

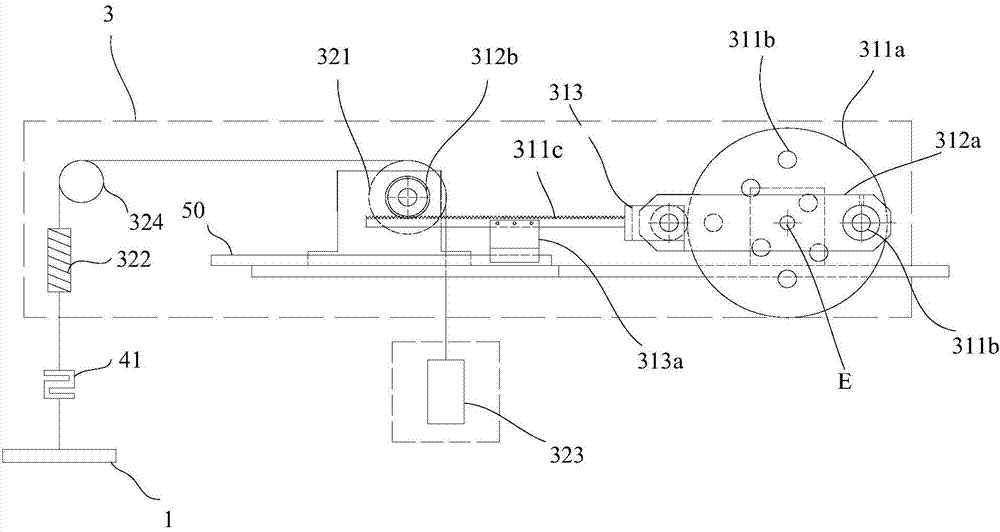

[0050] see image 3 , Figure 4 , the cyclic load l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com