Three-dimensional single-well gas injection oil replacement simulation experiment device for fracture-cavity reservoir

A simulation experiment device, three-dimensional single-well technology, applied in wellbore/well components, production fluid, earth-moving drilling and other directions, can solve the problems of inability to track, stay, and inaccurately measure the interphase interface, so as to meet the space requirements. Randomly distributed, broadly applicable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

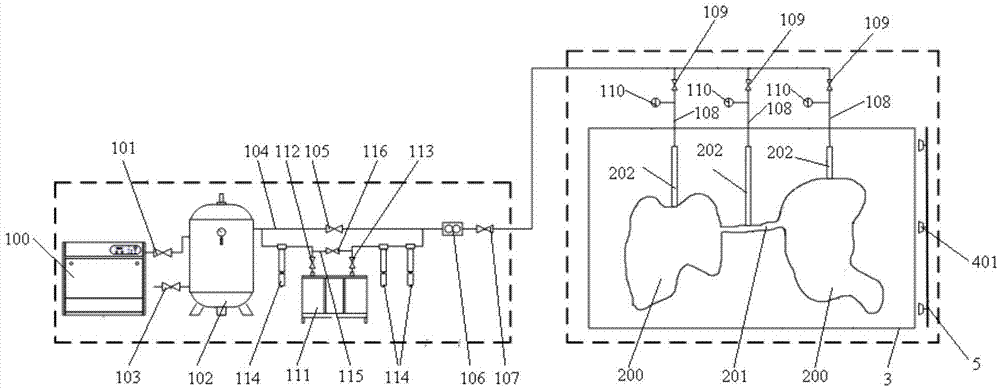

[0016] like figure 1 As shown, the three-dimensional single-well gas injection and oil replacement simulation experiment device of the present invention includes a gas injection system, a fracture-cavity simulation system connected to the gas injection system, and an image acquisition and information processing system. Wherein, the gas injection system includes a nitrogen storage tank 100, a compressor 102 connected to the output end of the storage tank 100 through a throttle valve 101, a vent valve 103 connected to the bottom end of the compressor 102, and a pipeline 104 connected to the output end of the compressor 102 A throttling valve 105, a flow meter 106 and a throttle valve 107 are arranged in sequence from the output end of the compressor 102 on the pipeline 104, and the pipeline at the output end of the throttle valve 107 is divided into three branches 108, each The branches 108 are connected to the crack and hole simulation system through a throttle valve 109 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com