Full 3D simulation visual displacement simulation experiment system for fracture-vuggy reservoirs

A technology of three-dimensional simulation and displacement simulation, which is applied in the field of reservoir research, can solve the problems of incapable of real-time and accurate monitoring of pressure and flow field changes, and achieve functional diversity and flexibility, shape and scale diversification, and simple structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

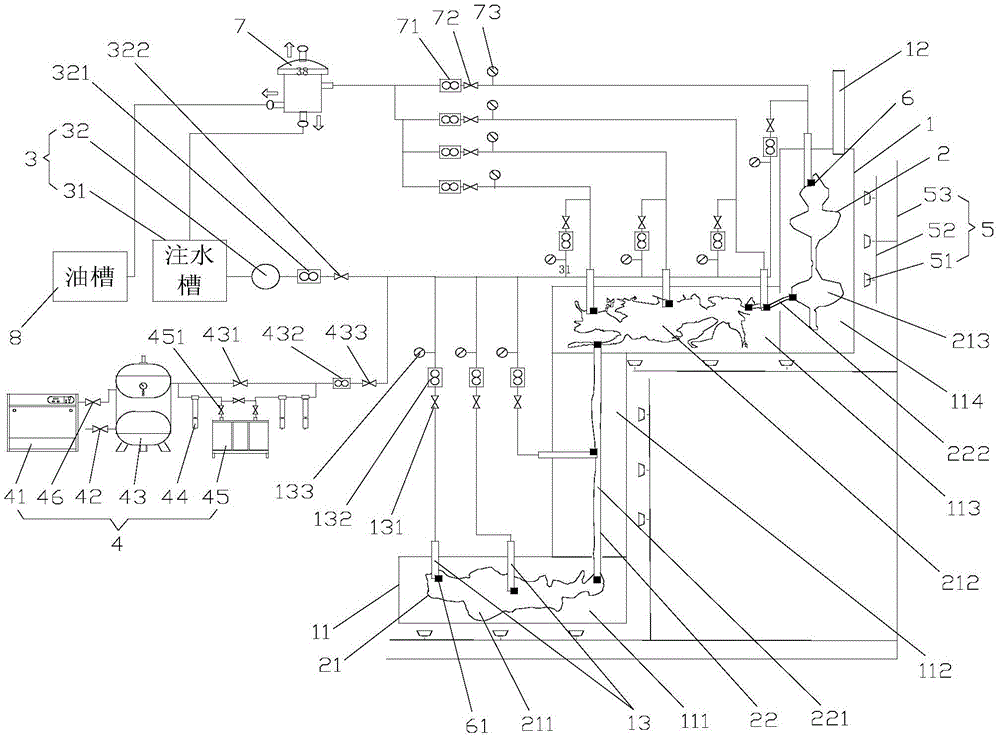

[0029] like Figures 1 to 3 As shown, the full three-dimensional simulation visual displacement simulation experiment system for fracture-vuggy reservoirs of the present invention includes a tank simulation unit 1 and a fracture-cave model simulation unit 2 connected to the tank simulation unit 1, a water injection simulation unit 3, and a gas injection simulation unit. 4. Image acquisition simulation unit 5 , data acquisition simulation unit 6 , simulated three-phase separator 7 and simulated oil tank 8 .

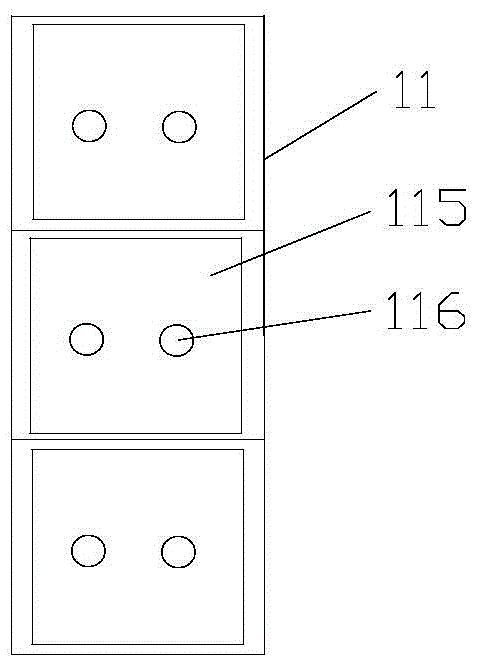

[0030] The tank simulation unit 1 includes a cubic tank 11, a glass tube 12 and a shaft 13; the cubic tank 11 is made of transparent plexiglass, which can be observed in real time; Each end surface is provided with an open plate 115 which can be opened, and the open plate 115 is provided with a hole 116 . Since the cubic water tank 11 has all-round openings, any combination of spaces of the water tank can be realized as required. Wherein, the cubic water tank 11 in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com