Manufacturing method of fishtail generating set with double lift rotors

A technology of water flow power generation and manufacturing method, which is applied in the direction of hydroelectric power generation, reaction engine, engine components, etc., can solve the problems of high cost, low utilization rate of water energy, complex structure, etc., and achieve improved power generation efficiency, simple structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

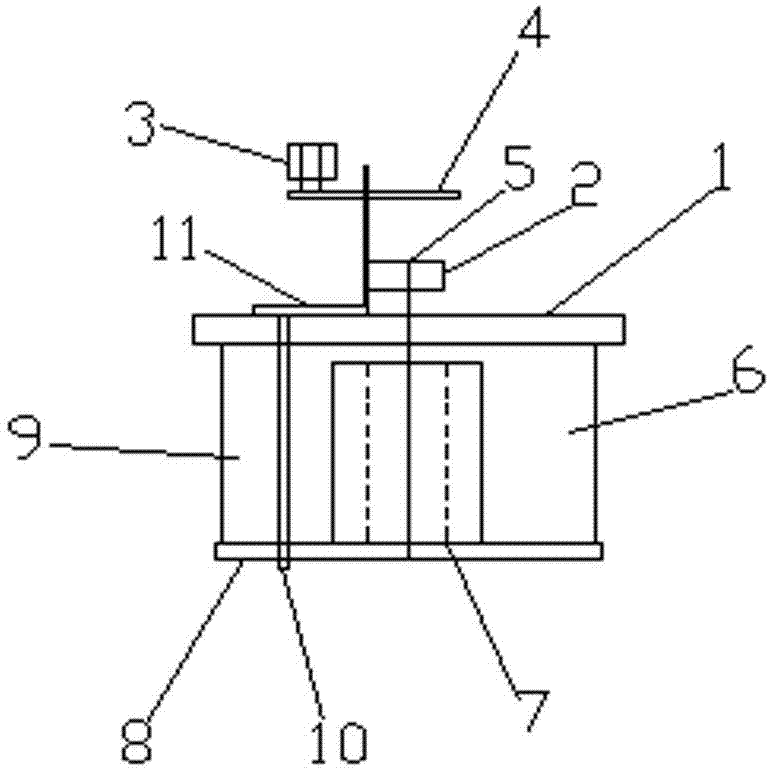

[0013] according to figure 1 Shown, a kind of manufacturing method of lift double-rotor fishtail type hydroelectric generating device, its steps are as follows:

[0014] (1) The upper cover plate 1, the upper left of the upper cover plate 1 is connected with the bearing plate 11, and the lower part of the upper cover plate 1 is connected with the rotating shaft 10; the generator 3 is connected with the intermediate gear 4, and the intermediate gear 4 and the bearing plate 11 pass through The drive gears are connected; the left side of the rotating shaft 10 has a sub-water body 9, the right side is a lift type rotor 7, and the fishtail rudder plate 6 is connected with the lift type rotor 7; the lower bottom plate 8;

[0015] (2) The upper left of the upper cover is connected with a bearing plate, and the lower part is connected with the rotating shaft 10 and the lower bottom plate;

[0016] (3) The generator is connected with the intermediate gear;

[0017] (4) The intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com