Self-gasification combustor

A burner and combustion chamber technology, applied in the directions of burners, burners, liquid fuel burners, etc., can solve the problems of high cost, unfavorable installation, inconvenient maintenance, etc., and achieve the effect of increasing the scope of use and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

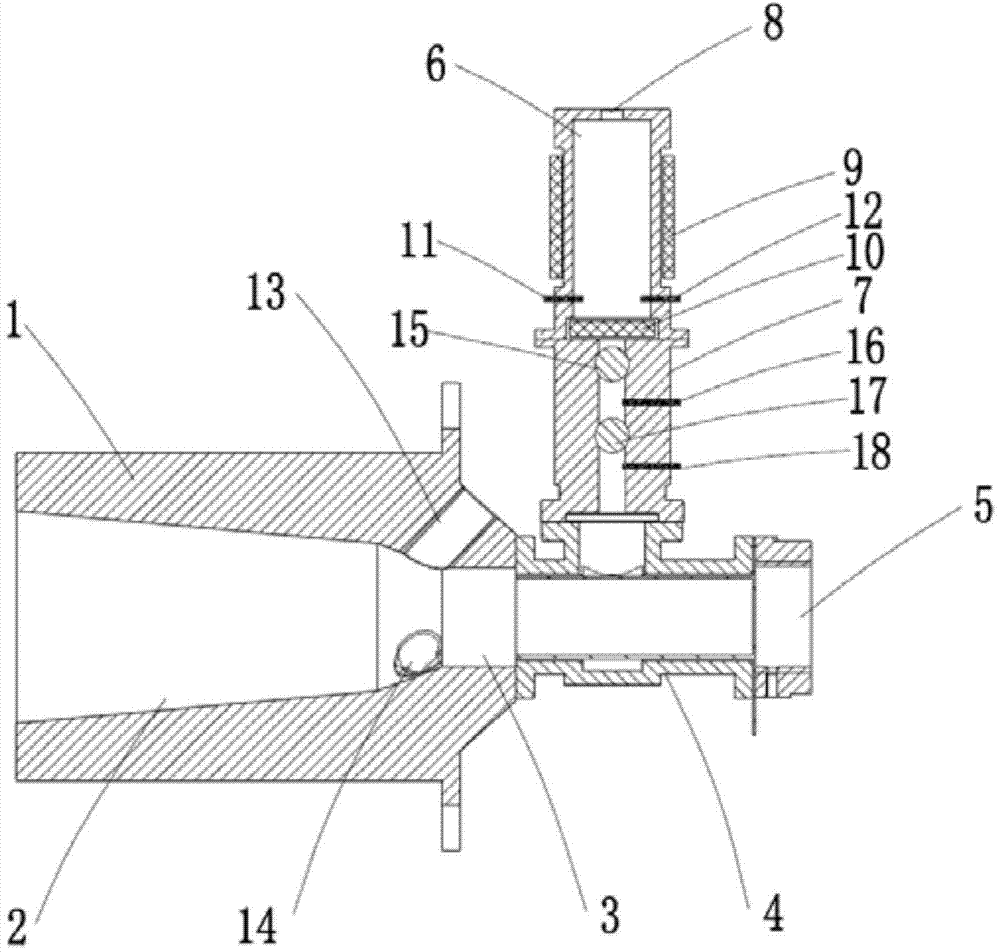

[0021] Embodiment: In conjunction with the accompanying drawings, the self-gasification burner of this embodiment includes:

[0022] The inner cavity of the burner body 1 is the combustion chamber 2, and the end of the burner body at the entrance of the combustion chamber 2 is set as the mixing chamber 3; the burner body between the combustion chamber 2 and the mixing chamber 3 is provided with an ignition port 13 And the fire port 14.

[0023] A gas and air passage 4 is provided, the inlet end of the gas and air passage is the combustion air inlet 5 , and the outlet end communicates with the mixing chamber 3 .

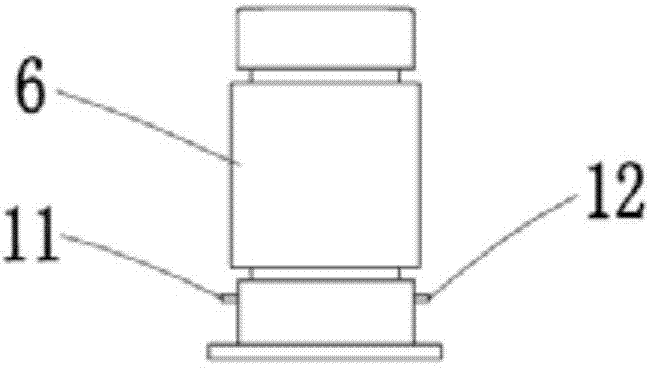

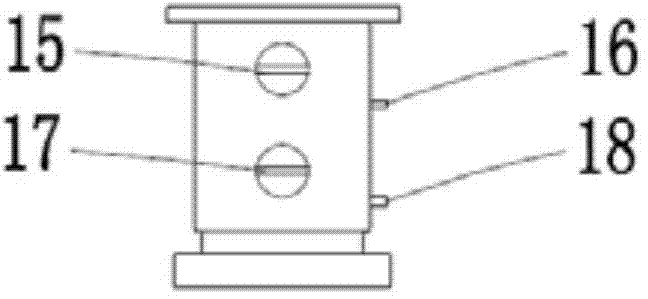

[0024] A gasification chamber 6 and a pressure regulator 7 connected to the outlet end of the gasification chamber are provided, wherein the inlet end of the gasification chamber 6 is a liquid combustible gas inlet 8, and the outlet end of the pressure regulator communicates with the gas and air channels 4. The outside of the gasification chamber 6 is surrounded by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com