Tire stiffness testing device

A technology for testing device and tire stiffness, applied in the direction of automobile tire testing, etc., can solve the problem of rare device, and achieve the effect of simple structure, reduced pressure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

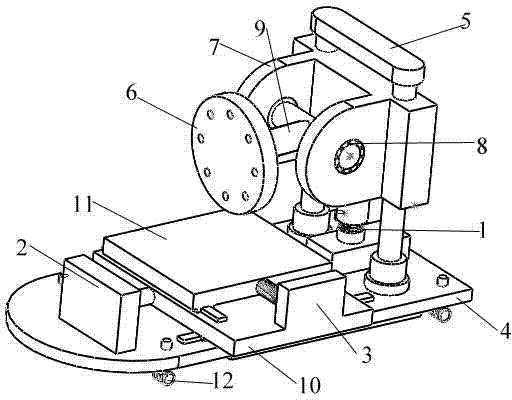

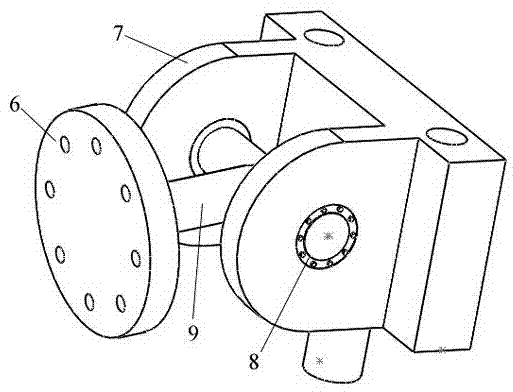

[0018] Such as Figures 1 to 2 As shown, the tire stiffness testing device of the present invention comprises: a vertical loading device 1, a lateral loading device 2, a longitudinal loading device 3, a base 4, a frame 5 fixed on the base 4 by two guide rails, a roll axis 6, The connecting piece 7, the expansion joint sleeve 8, the first plane 10 connected with the base 4 through the longitudinal guide rail, the second plane 11 connected with the first plane 10 through the transverse guide rail; the connecting piece 7, the first plane 10, the second plane 10 Both planes 11 are provided with linear displacement sensors.

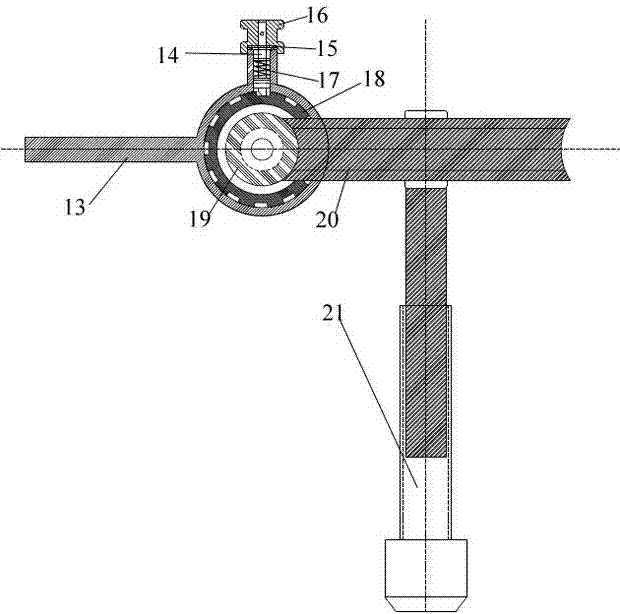

[0019] Such as Figures 1 to 2 As shown, the tilting shaft 6 is connected to the connecting piece 7 through two expansion joints 8; the connecting piece 7 is provided with a six-component force sensor 9; the connecting piece 7 is provided with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com