Method for rapidly determining ash content of filled paper by adopting portable gas stove

A rapid measurement, cassette furnace technology, applied in the direction of removing a certain component and weighing, etc., can solve the problems of inability to completely burn the organic matter in the paper, the need, and the large temperature shock, so as to shorten the ash content measurement time and ensure the accuracy. , the effect of long heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

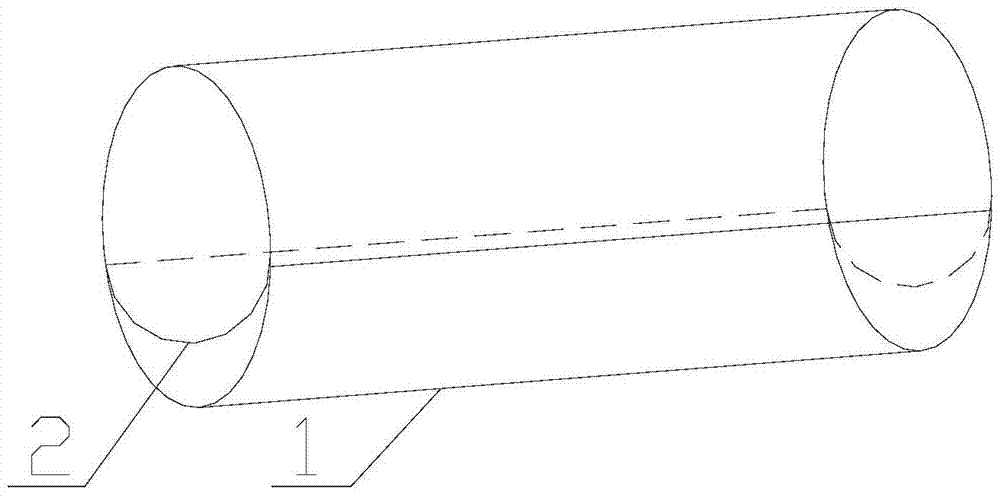

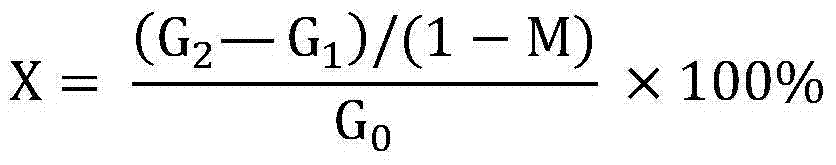

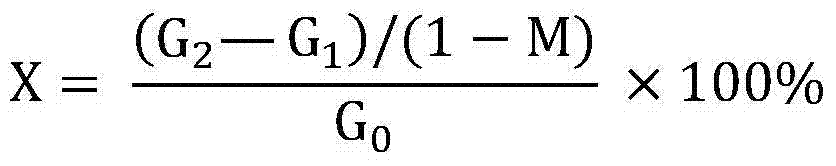

Embodiment 1

[0046] Coated paper (quantitative 125g / m 2 ), take 0.5g of coated paper and cut it into several paper strips with a length of 50mm and a width of 40mm, place the paper strips completely overlapping and fold them in half along the length direction to form 70-145 degrees, and use an analytical balance (0.0001g) to weigh the paper sample and After the weight of the burning device used to place the paper pattern, put the paper pattern into the support frame 2 in the burning device, and then place the whole burning device on the butane card-type furnace for burning. The vertical distance between the burning device and the card-type furnace head The control is 15mm, and the card-type furnace is used to burn the paper sample at high temperature for 3 minutes, then the combustion device is cooled in the air for 20 seconds, and then placed in a desiccator to cool for 3 minutes, and then weighed on an analytical balance, and finally the ash value is obtained by calculation, repeat Calcu...

Embodiment 2

[0050] Coated white cardboard (quantitative 230g / m 2 ), cut 0.5g of coated white cardboard into several paper strips with a length of 40mm and a width of 10mm, place the paper strips completely overlapping and fold them in half along the length direction to form 70-145 degrees, and use an analytical balance (0.0001g) to weigh After measuring the weight of the paper sample and the burning device used to place the paper sample, put the paper sample into the support frame 2 in the burning device, and then place the whole burning device on the butane card-type furnace for burning, the burning device and the card-type furnace The vertical distance of the head is controlled at 10mm, and the paper sample is burned at a high temperature in a cassette furnace for 2 minutes, then the combustion device is cooled in the air for 10 seconds, and then placed in a desiccator for 2 minutes, then weighed on an analytical balance, and finally the ash content is obtained by calculation Values w...

Embodiment 3

[0055] Sketch paper (quantitative 150g / m 2), take 0.5g of sketch paper and cut it into several paper strips with a length of 90mm and a width of 50mm, place the paper strips completely overlapping and fold them in half along the length direction to form 70-145 degrees, and use an analytical balance (0.0001g) to weigh the paper sample and After the weight of the burning device used to place the paper pattern, put the paper pattern into the support frame 2 in the burning device, and then place the whole burning device on the butane card-type furnace for burning. The vertical distance between the burning device and the card-type furnace head The control is 30mm, use a cassette furnace to burn the paper sample at a high temperature for 10 minutes, then cool the combustion device in the air for 30 seconds, then place it in a dryer for 6 minutes, then weigh it on an analytical balance, and finally obtain its ash value by calculation, repeat Calculate the average value after several ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com