Display panel and manufacturing method thereof

A technology for display panels and substrates, applied in the directions of picture replicators, optics, instruments, etc., can solve the problems affecting the aperture ratio of the display panel and the reduction of the area of the light-transmitting area, so as to achieve the same component characteristics and improve the aperture ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those who are familiar with the technical field of the present invention to further understand the present invention, the preferred embodiments of the present invention are enumerated below, together with the accompanying drawings, to describe in detail the composition of the present invention and the desired effects .

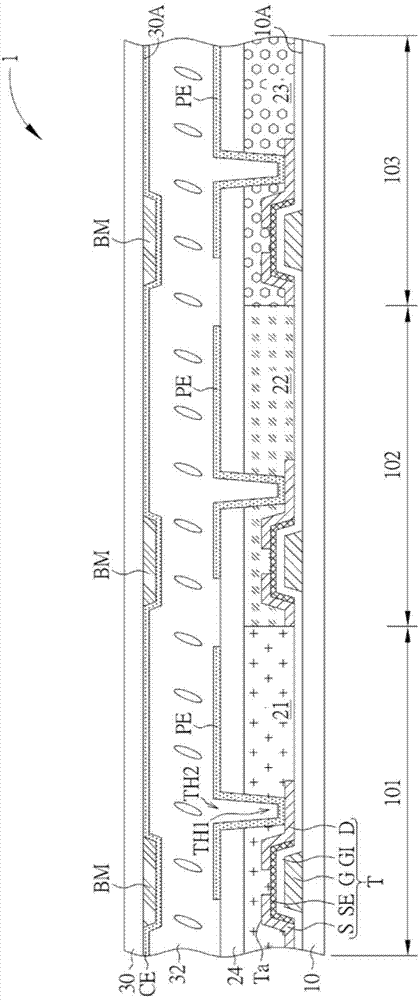

[0040] Please refer to figure 1 . figure 1 A schematic diagram of a display panel of a comparative example of the present invention is shown. Such as figure 1As shown, the display panel 1 of the comparative embodiment includes a first substrate 10, a plurality of thin film transistor elements T, a first color filter layer 21, a second color filter layer 22, a third color filter layer 23, and a plurality of pixels The electrode PE, the second substrate 30 , the photoelectric medium layer 32 , the black matrix BM and the common electrode CE. The first substrate 10 is an array substrate, which can be a transparent substrate such as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com