Manufacturing method of memory apparatus, memory device and memory apparatus

A technology for storage devices and manufacturing methods, applied in static memory, digital memory information, information storage, etc., can solve problems such as small size or interval, difficulty in obtaining element characteristics, and changes in contact area, so as to achieve improved element characteristics and consistent element characteristics , reducing the effect of misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0035] 1. First embodiment (example in which the planar shape of the lower electrode is a quadrilateral)

[0036] 2. Second embodiment (example in which insulating side walls are provided on the same side of two opposite sides of a quadrangle)

[0037] 1. The first embodiment

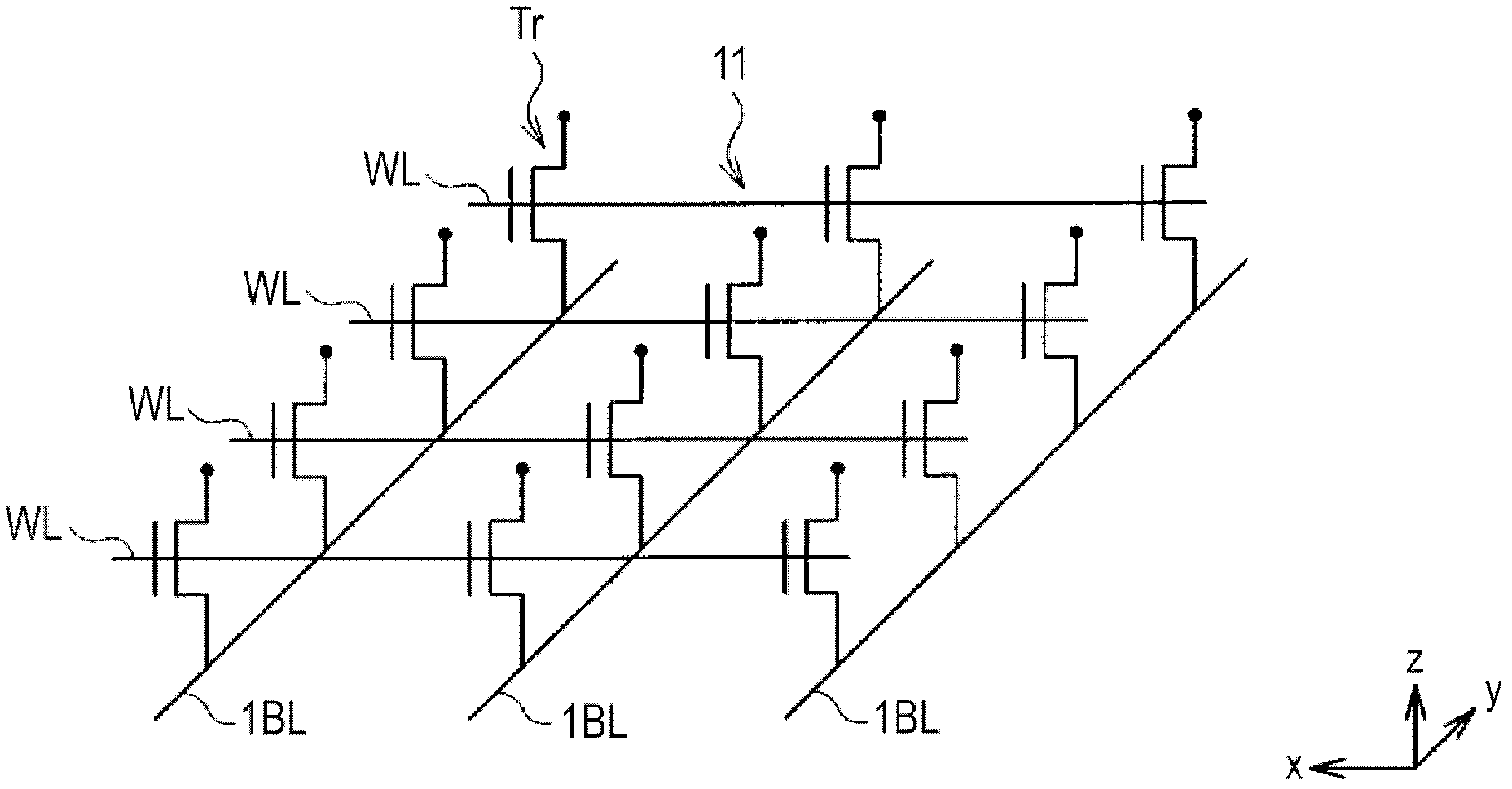

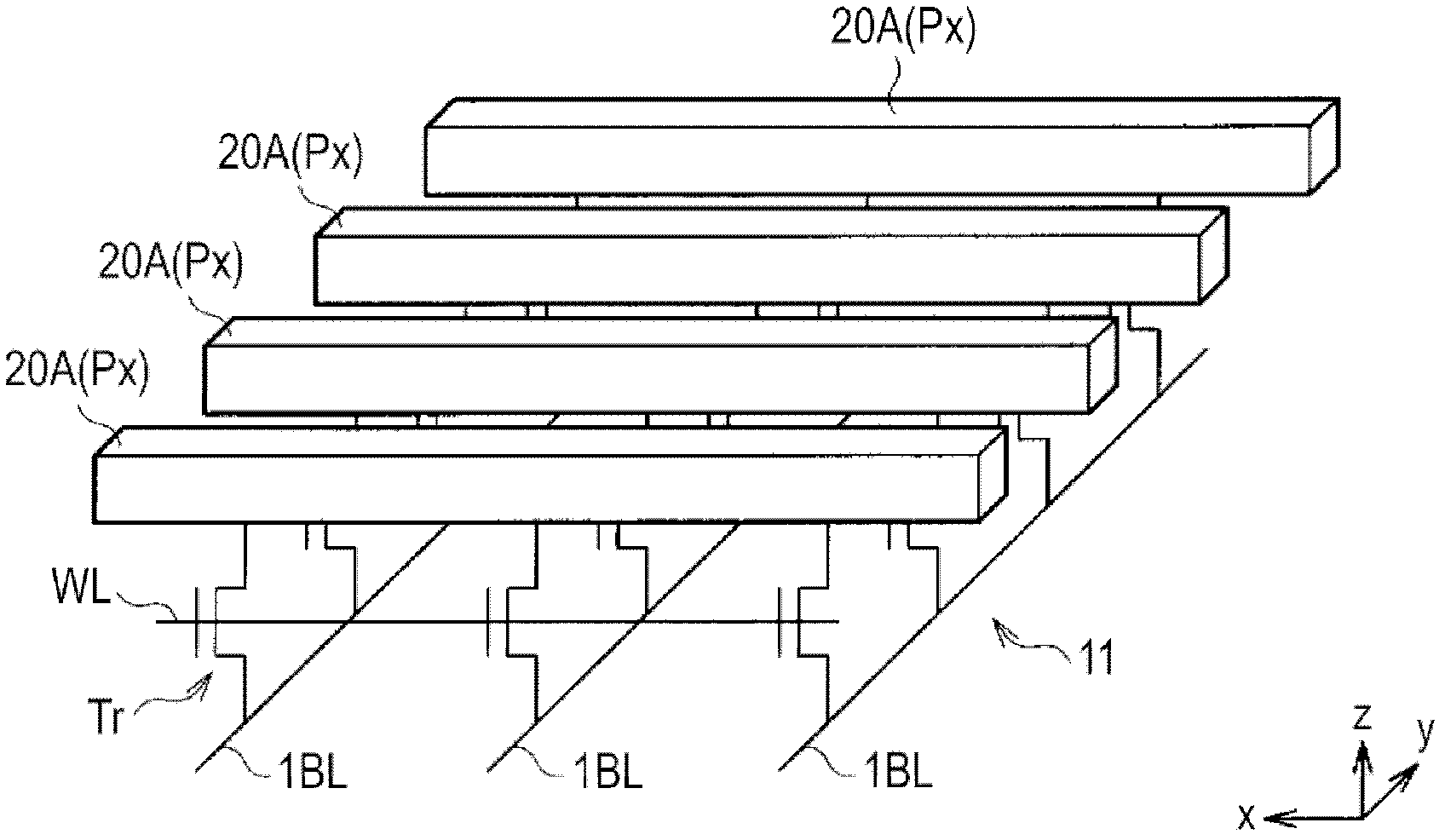

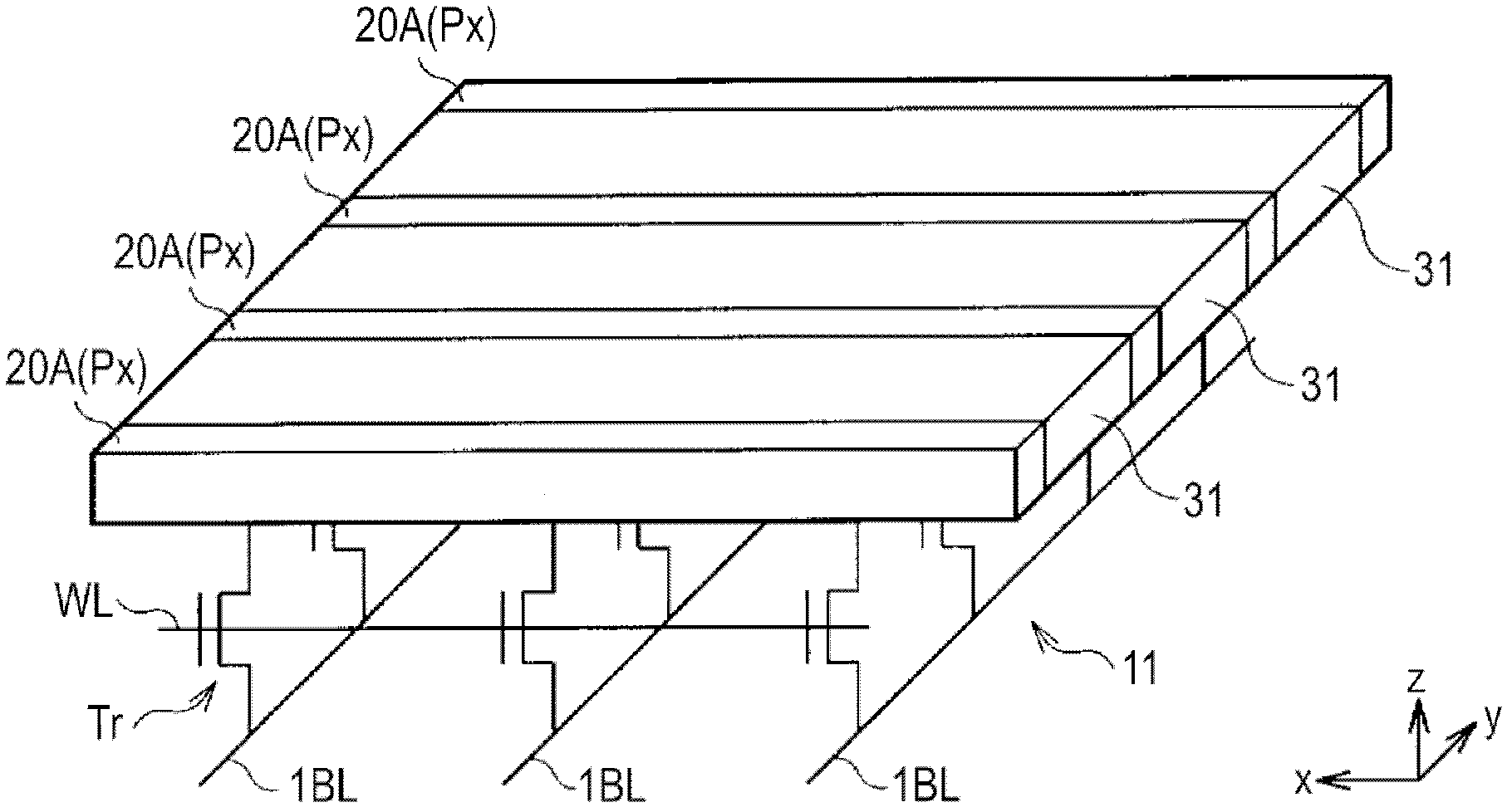

[0038] Figure 1-Figure 6 and Figure 12 The manufacturing method of the storage device according to the first embodiment of the present invention is shown in order of procedures. First, if figure 1 As shown, on the substrate 10 ( figure 1 not shown, see Figure 7 ) to form a transistor array 11, and the substrate 10 is a silicon wafer or the like. In the transistor array 11, the first bit lines 1BL and the word lines WL are formed in a matrix state, and at the same time, the transistors Tr are arranged at intersections of the first bit lines 1BL and the word lines WL. One of the source and the drain of the transistor Tr is connected to a lower electrode 20 (to be described later) of each memory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com