Checking system of warehouse materials

A material and warehouse technology, used in logistics, instruments, data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

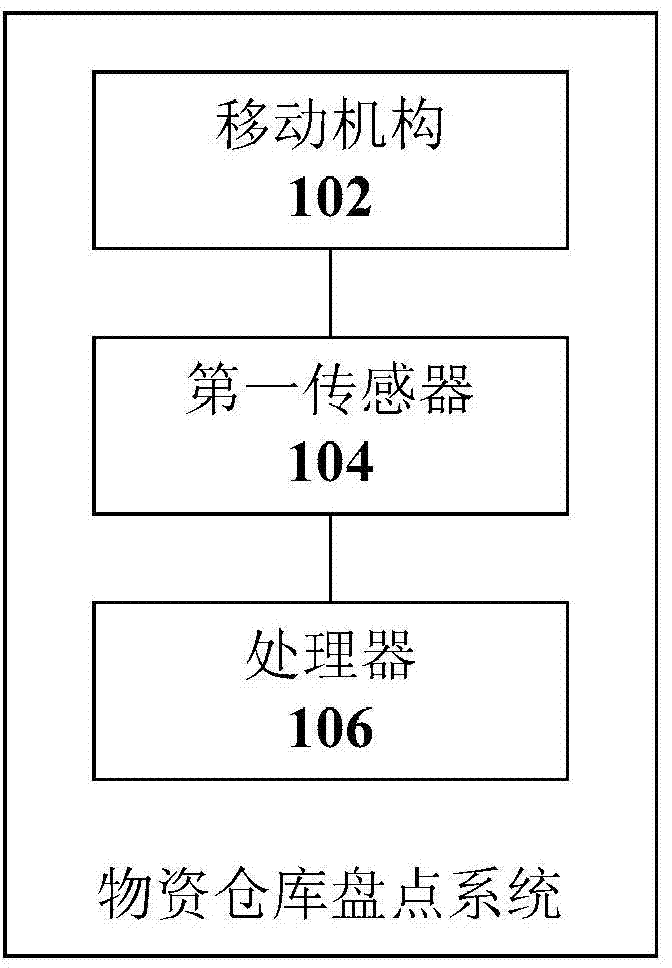

[0024] According to an embodiment of the present invention, a material warehouse inventory system is provided, such as figure 1 As shown, the system includes:

[0025] 1) The moving mechanism 102 is used to move in the material warehouse. The moving path of the moving mechanism 102 corresponds to a predetermined storage location set, and the predetermined storage location set includes a predetermined storage location in the material warehouse for each of the multiple materials to be counted;

[0026] 2) The first sensor 104 is arranged on the moving mechanism 102, and is used to follow the moving mechanism 102 to sense the materials actually stored in each predetermined storage location, and output an identification signal corresponding to the actually stored materials;

[0027] 3) The processor 106, connected to the first sensor 104, is used to judge according to the identification signal whether each predetermined storage location in the set of predetermined storage location...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com