Combined harvester with good power performance

A technology of combine harvester and dynamic performance, which is applied in the direction of harvesters, cutters, and lifting devices of agricultural machinery, etc., can solve the problems of harvesting and missing cutting of grain ears that cannot be lodged, and achieves good dynamic performance, reduces economic losses, Reduce the effect of missed cuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

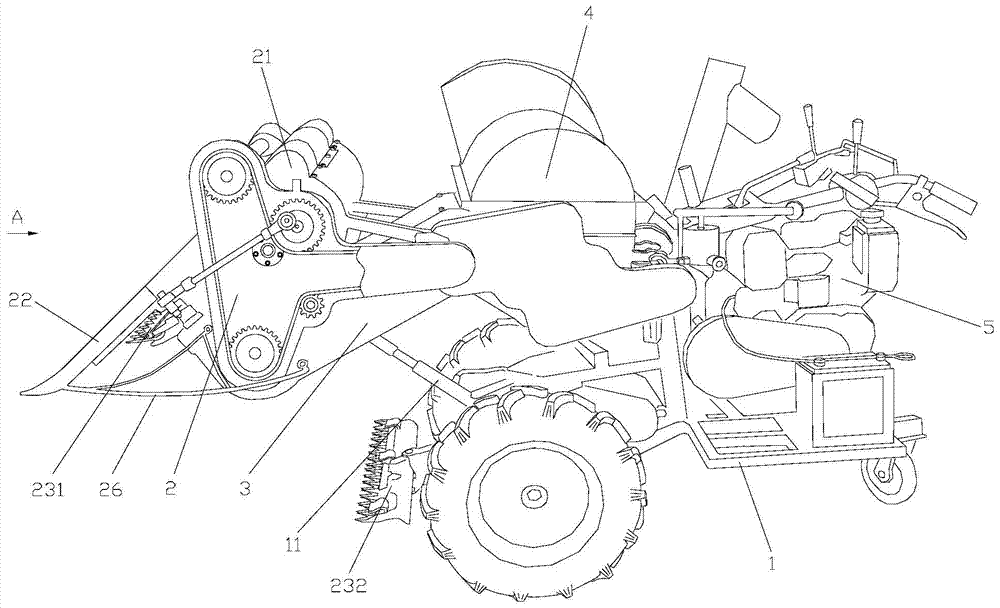

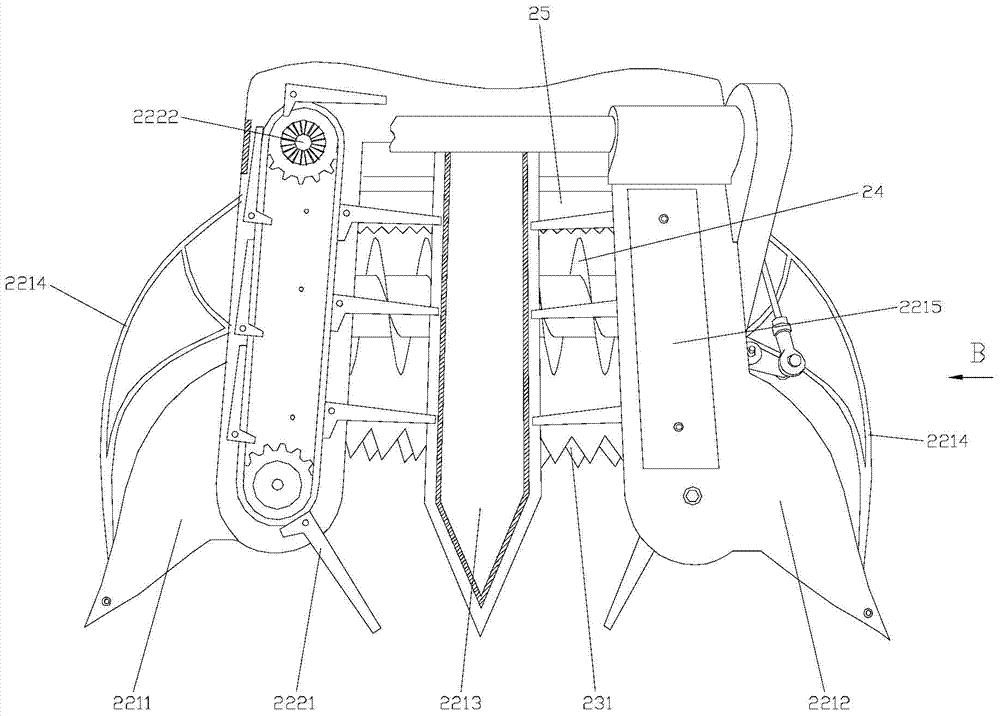

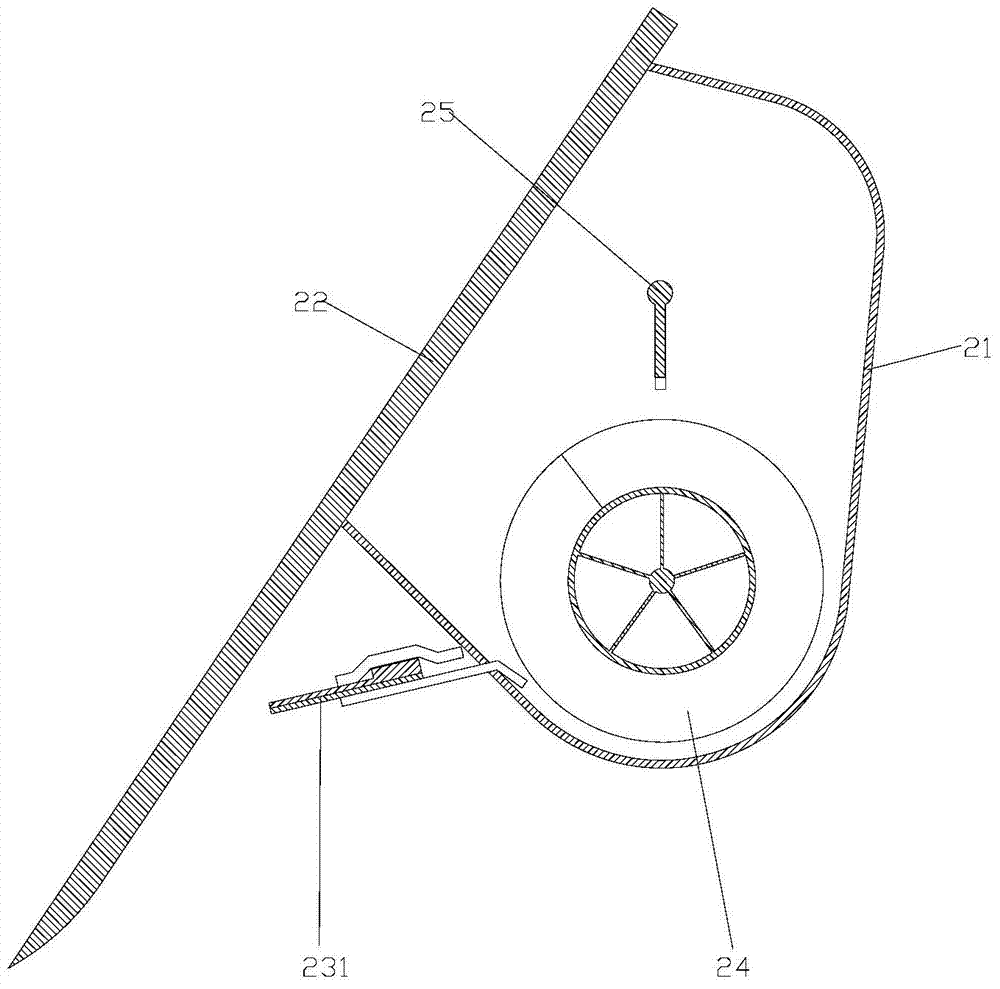

[0023] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Partial view of A, image 3 for figure 2 Partial sectional view of B direction, Figure 4 It is a partial sectional view of the grain divider, Figure 5 It is a schematic diagram of the flywheel structure; as shown in the figure: the good combine harvester of the present embodiment includes a walking car body 1, a harvesting part 2, a conveying device 3, a threshing part 4 and an engine 5, and the harvesting part 2 is arranged on The front part of the walking vehicle body 1 includes a bracket shell I21, a grain raising device 22, a cutting edge 23 and a push auger 24, and the grain raising device 22 includes a grain dividing part 221 and a grain raising part 222, and the grain dividing part 221 It is fixedly arranged on the front part of the bracket shell I21 and its upper end is inclined backward. The grain holding part 222 includes a grain holding finger 2221 that can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com