Assembly method of high pressure airless sprayer

A high-pressure airless, assembly method technology, applied in the direction of injection devices, liquid injection devices, etc., can solve the problems that pipelines and mechanical components are easily impacted by foreign objects, components are easily damaged, paints and coatings are easy to pollute pipelines and mechanical components, etc. Achieve the effect of superior spraying performance, low power consumption, and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

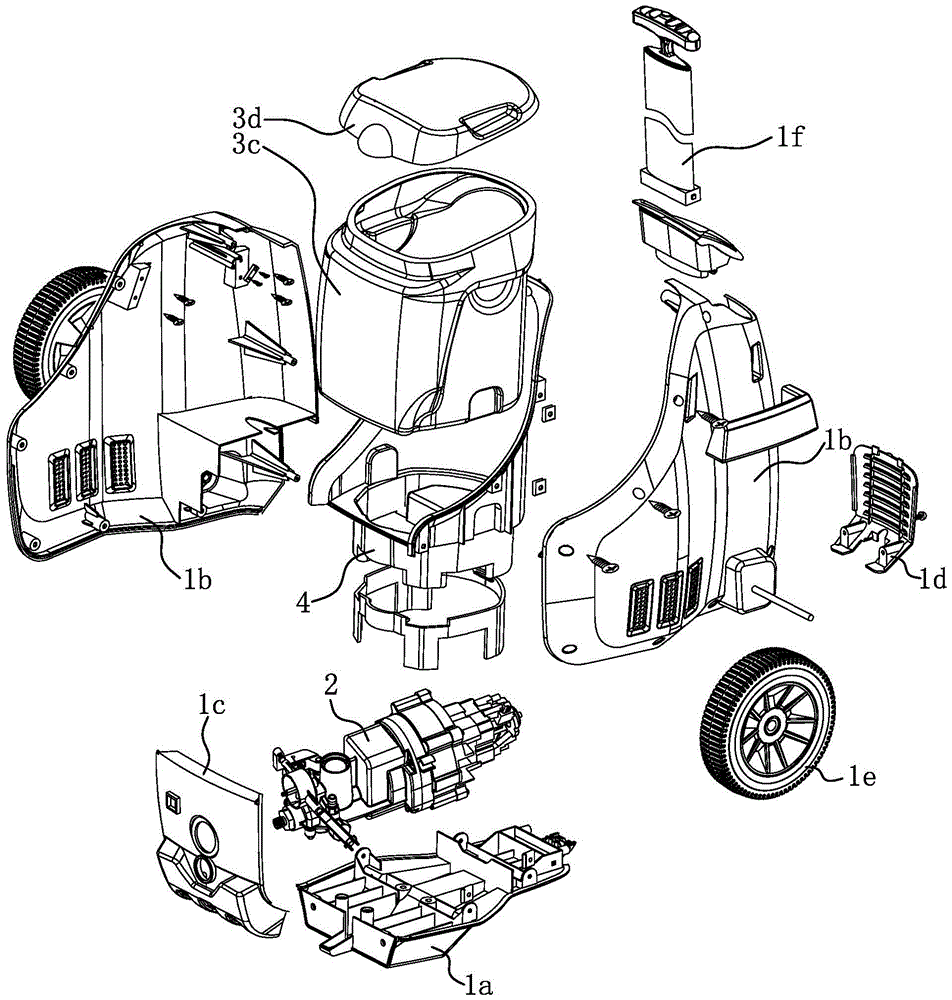

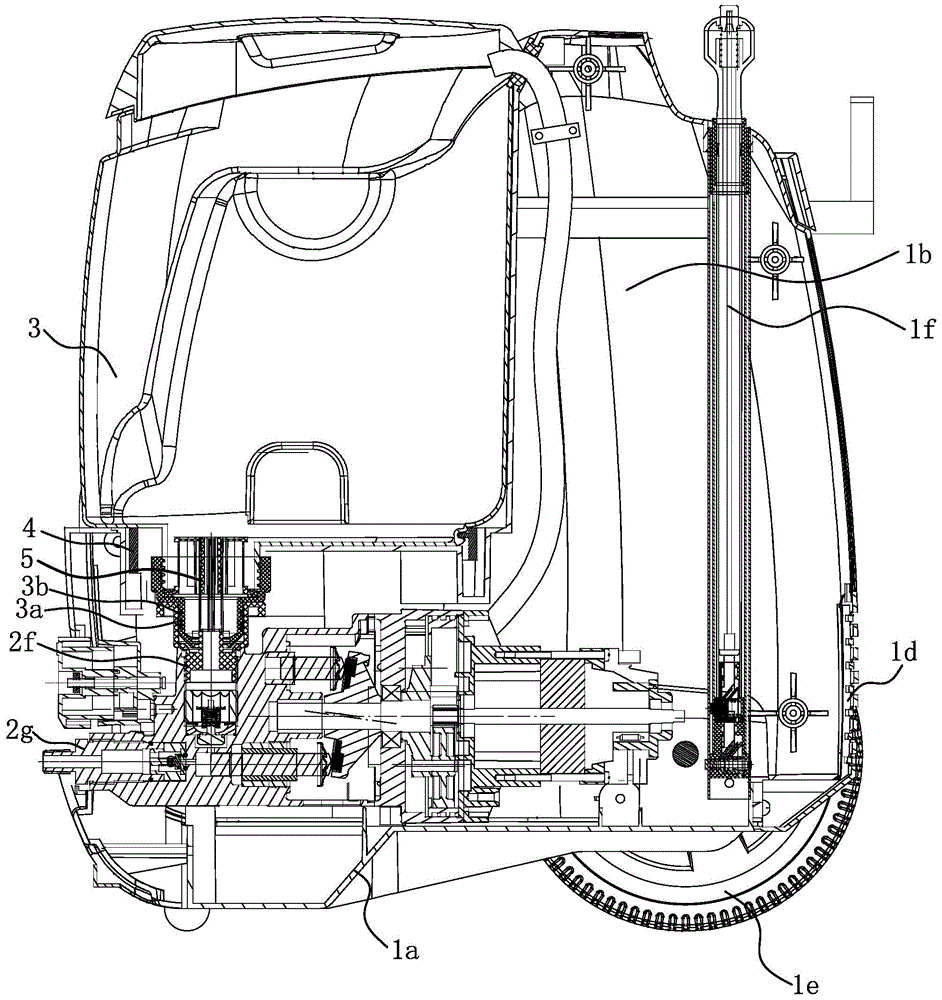

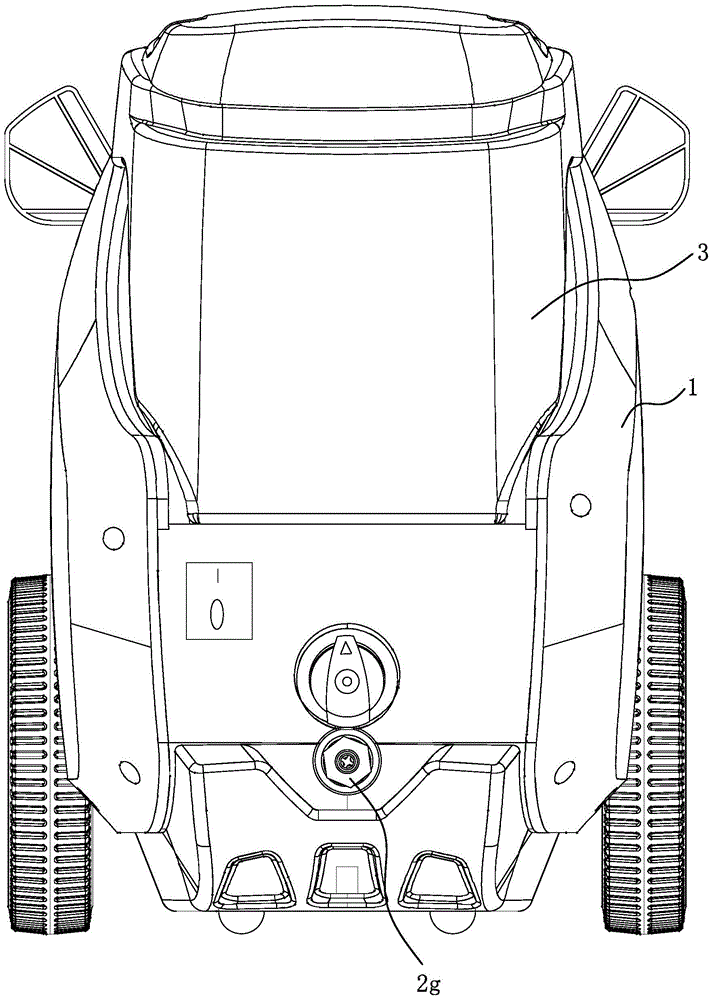

[0026] Such as Figure 1 to Figure 16 As shown, the high-pressure airless sprayer includes a case bag 1, an electric plunger pump 2 and a barrel 3.

[0027] The case bag 1 is a basic part, and the case bag 1 has a cavity. The case bag 1 has a bottom board 1a, two side boards 1b, a front board 1c, a rear cover board 1d, two rolling wheels 1e and a set of telescopic pull rods 1f. The two scroll wheels 1e are installed on the two side plates 1b in one-to-one correspondence. There are a plurality of air holes on the two side panels 1b and one rear cover panel 1d. Both side panels 1b have first handles, so the high-pressure airless sprayer can be pulled and lifted, so it is very convenient to carry.

[0028] The electric pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com