Mold for large-size ultrathin washing machine plastic backing plate

A washing machine, large-size technology, applied in the field of molds for large-size ultra-thin washing machine plastic backplanes, to achieve the effect of infusion in place, simple structure, and rapid prototyping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions and beneficial effects of the present invention will be clearer and more definite by further describing the specific embodiments of the present invention in conjunction with the accompanying drawings.

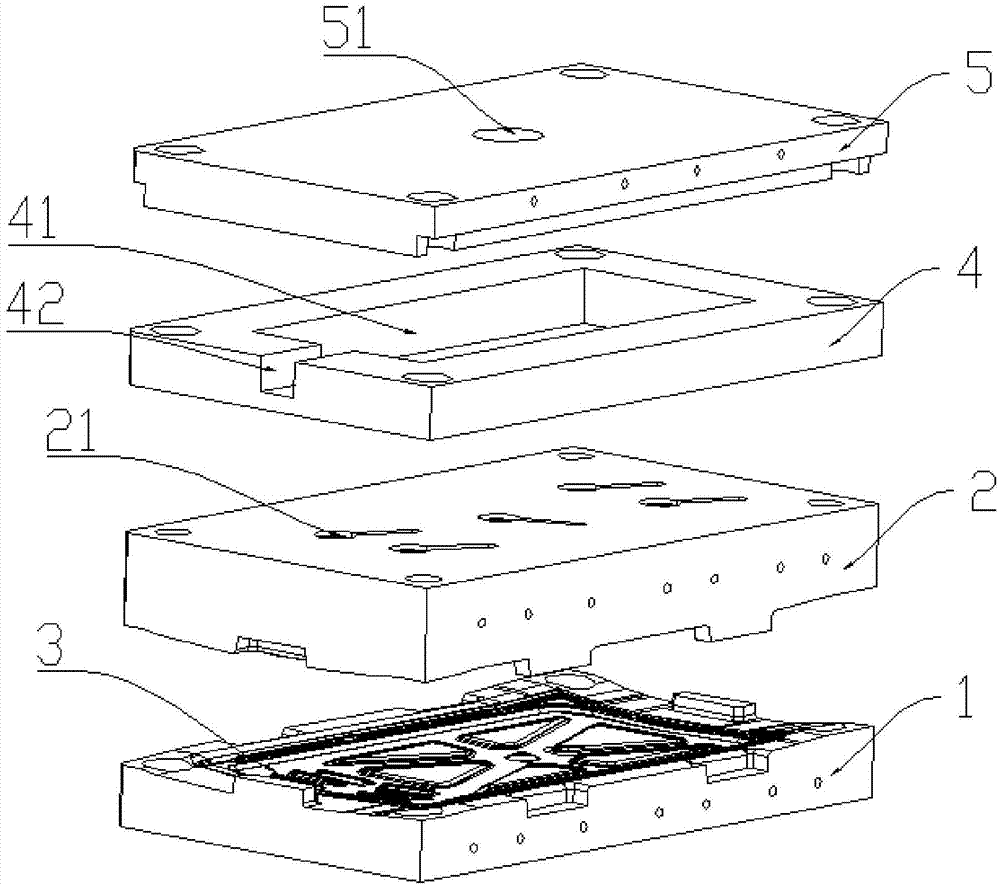

[0011] See attached figure 1 , the present invention includes a fixed mold 1 and a movable mold 2 cooperating with each other, a mold core groove 3 is provided between the fixed mold 1 and the movable mold 2; a hot mold 4 and an upper mold 5 are arranged above the movable mold 2, so that The upper mold 5 is located above the hot mold 4, and it is characterized in that: the movable mold 2 is provided with more than five vertical injection ports 21, and the injection ports 21 are evenly distributed on the movable mold 2;

[0012] Further, the hot mold 4 is provided with a pouring groove 41 matching with the injection port 21, and the hot mold 4 is provided with an overflow groove 42 matching with the pouring groove 41;

[0013] Further, the upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com