Bi-material vertical injection molding device

An injection molding, dual-material technology, applied in the field of dual-material vertical injection molding equipment, can solve problems such as low efficiency, achieve high efficiency, wide applicability, and reduce injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

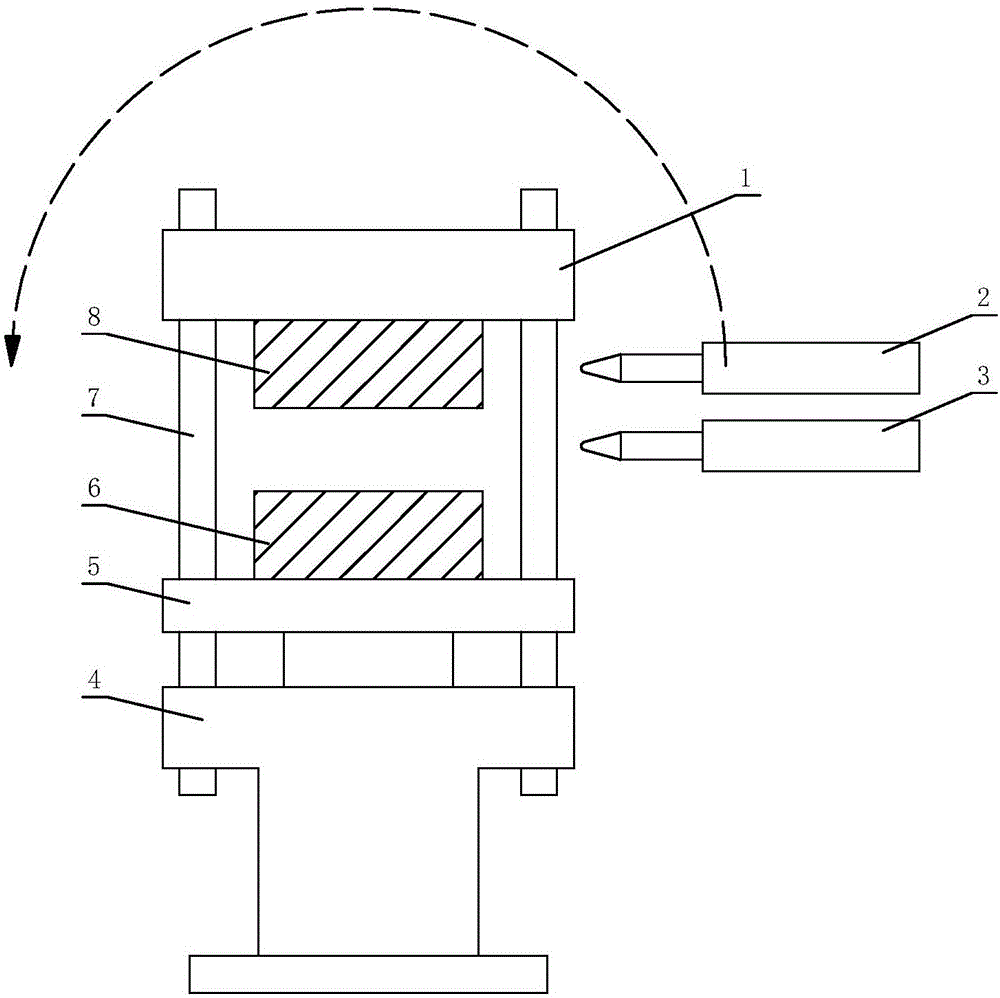

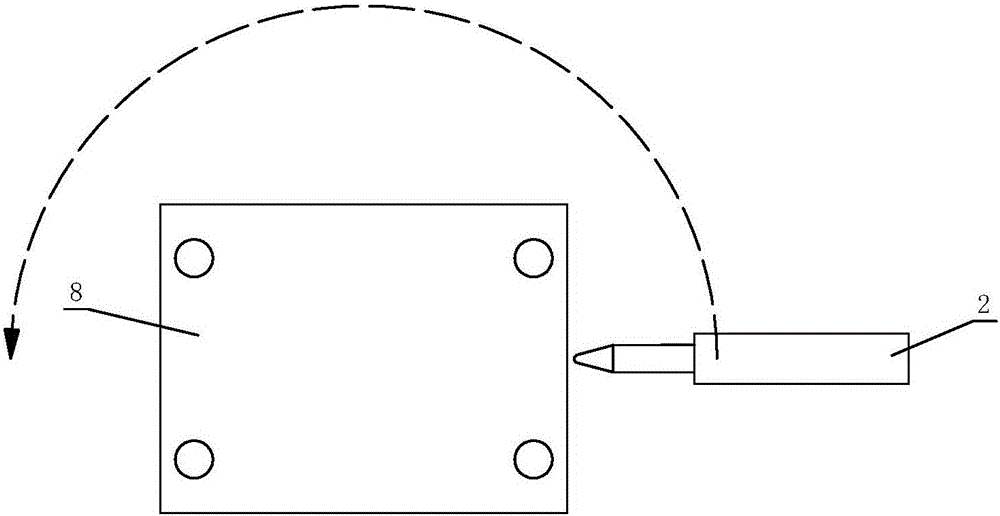

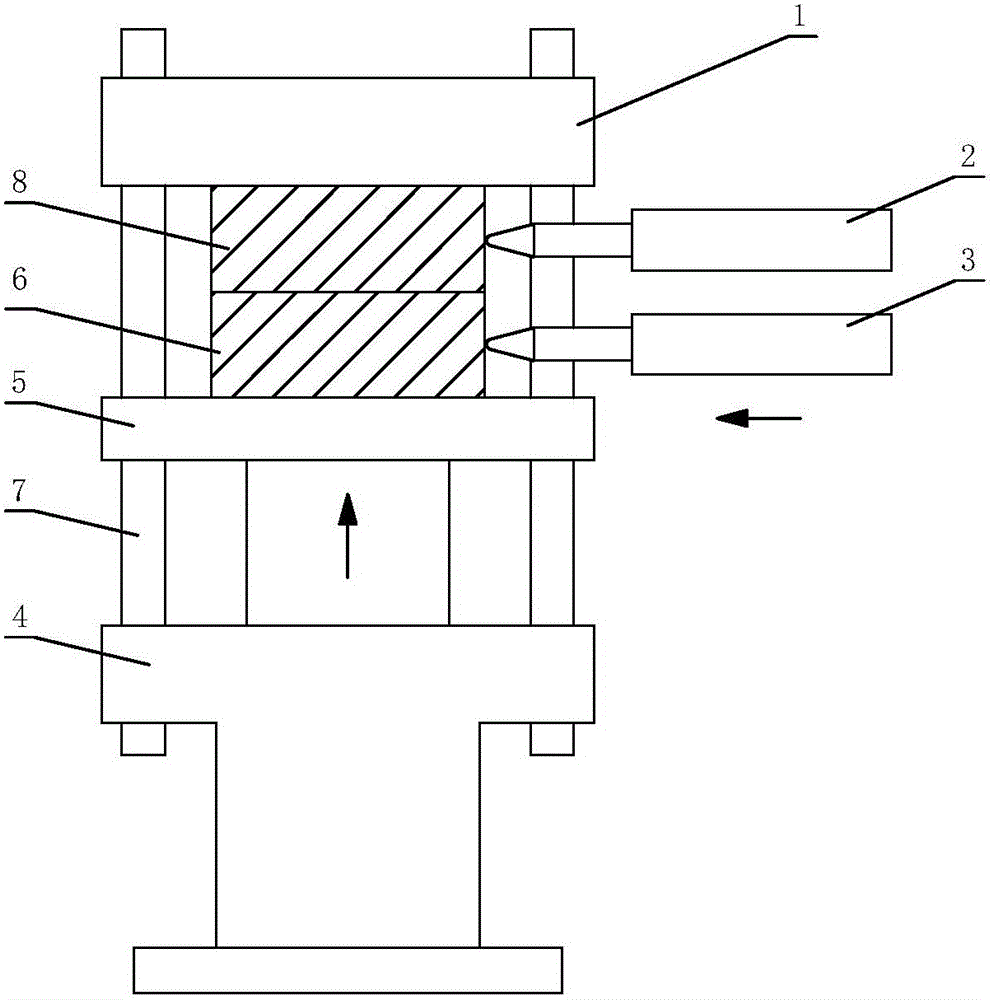

[0019] see Figure 1-Figure 3 , the dual-material vertical injection molding equipment includes an upper mold 8 and a lower mold 6 for vertical clamping. The upper mold 8 and the lower mold 6 are respectively equipped with an upper injection device 2 and a lower injection device 3. The upper injection The device 2 and the lower injection device 3 are independent of each other and do not interfere with each other; in the mold-locked state, the upper injection device 2 and the lower injection device 3 inject glue to the upper mold 8 and the lower mold 6 respectively. The top of the upper mold 8 is equipped with an upper template 1, and the bottom of the lower mold 5 is equipped with a lower template 5. The upper template 1 and the lower template 5 are relatively positioned and moved by setting the column 7, so that the upper mold 8 and the lower mold 6 are vertically locked. mold. This structure also includes the mold clamping master cylinder 4, which is the power source for mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com