A long-travel constant contact elastic side bearing and vibration reduction method for railway freight cars

A railway freight car, long-stroke technology, applied in the direction of the device for lateral relative movement between the chassis and the bogie, can solve the problems of small stiffness change, large vertical stroke, small permanent deformation, etc., to achieve increased radial stiffness, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

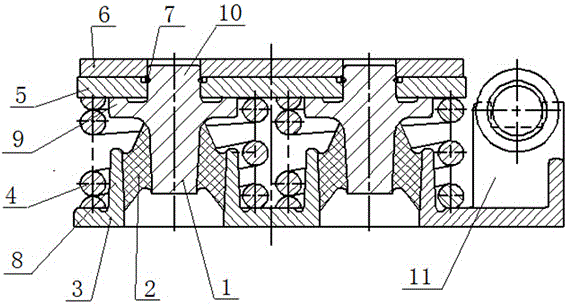

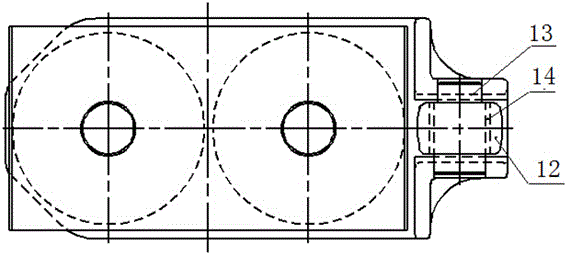

[0039] By attaching Figure 1-2 It can be seen that the present invention relates to a long-stroke, constant-contact elastic side bearing, which includes a side bearing lower body 3, a side bearing upper body 1, a side bearing bearing plate 5, a rubber body 2, and a metal spring 4. The side bearing upper body 1 is vulcanized into a whole by the rubber body 2, and is connected to the side bearing bearing plate 5 through the end of the side bearing upper body 1 to form two bushing rubber springs placed in parallel, which serve to transmit the side bearing longitudinal direction The function of the load: A metal spring 4 is fitted on the outside of each bushing rubber spring. The metal spring 4 is located between the side bearing lower body 3 and the bearing plate 5, and bears most of the vertical load of the side bearing.

[0040] The metal spring 4 is sleeved outside the contact sleeve 8 vulcanized by the side support lower body 3 and the rubber body 2, and the contact sleeve 8 of...

Embodiment 2

[0047] The principle of the second embodiment is the same as that of the first embodiment, including the side bearing lower body, the side bearing upper body, the side bearing bearing plate, the rubber body and the metal spring. The side bearing lower body and the two side bearing upper bodies are vulcanized into one by the rubber body. The whole body is connected with the side bearing bearing plate through the end of the side bearing upper body to form two bushing rubber springs placed in parallel, which play the role of transmitting the longitudinal load of the side bearing; set on the outside of each bushing rubber spring There is a metal spring, which is located between the lower body of the side bearing and the bearing plate, and bears most of the vertical load of the side bearing.

[0048] The metal spring is sleeved outside the vulcanized contact sleeve of the side bearing lower body and the rubber body, and the contact sleeve of the side bearing lower body is used as the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deflection | aaaaa | aaaaa |

| Deflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com