Adjustable cab double-torsion-bar turnover mechanism and assembling method

A technology of overturning mechanism and cab, which is applied in the field of truck cab overturning system, which can solve the problems of increased user cost, inconvenient adjustment, and difficult maintenance, etc., and achieves the effects of reduced maintenance cost, simple and convenient adjustment operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments, and the following description is only exemplary and does not limit the protection scope of the present invention.

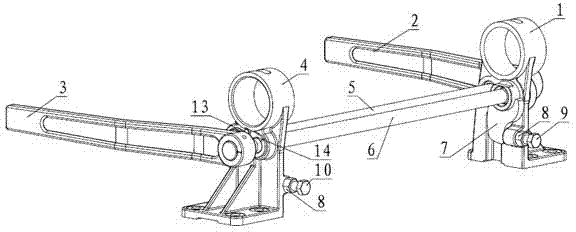

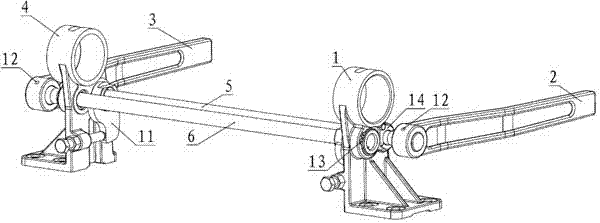

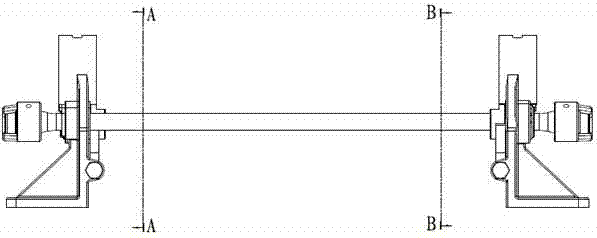

[0037] Reference attached Figure 1 to Figure 8 , an adjustable cab double torsion bar turning mechanism, including a support group, an adjustment group, a torsion arm group and a torsion bar group, wherein the support group includes a left support 1 and a right support 4, a left support 1 and a right The support 4 is relatively installed on the left and right sides of the frame at a certain distance; the adjustment group includes the left adjustment plate assembly, the right adjustment plate assembly 7, the left adjustment bolt nut assembly and the right adjustment bolt nut assembly, refer to the attached Figure 9 Wherein the left adjusting plate assembly 11 and the right adjusting plate assembly 7 all include a sleeve body 15 and a support plate frame 16 fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com