Rotary-wing drone with gearless-drive and fast-mounting propellers

An unmanned aircraft, unmanned rotor technology, applied in the direction of rotorcraft, toy planes, unmanned aerial vehicles, etc., can solve the problems of reduced size of unmanned aircraft, easy loss of locking parts, and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the invention will be described, which are given as non-limiting examples only, and many variations of the different elements described are conceivable without departing from the framework of the invention.

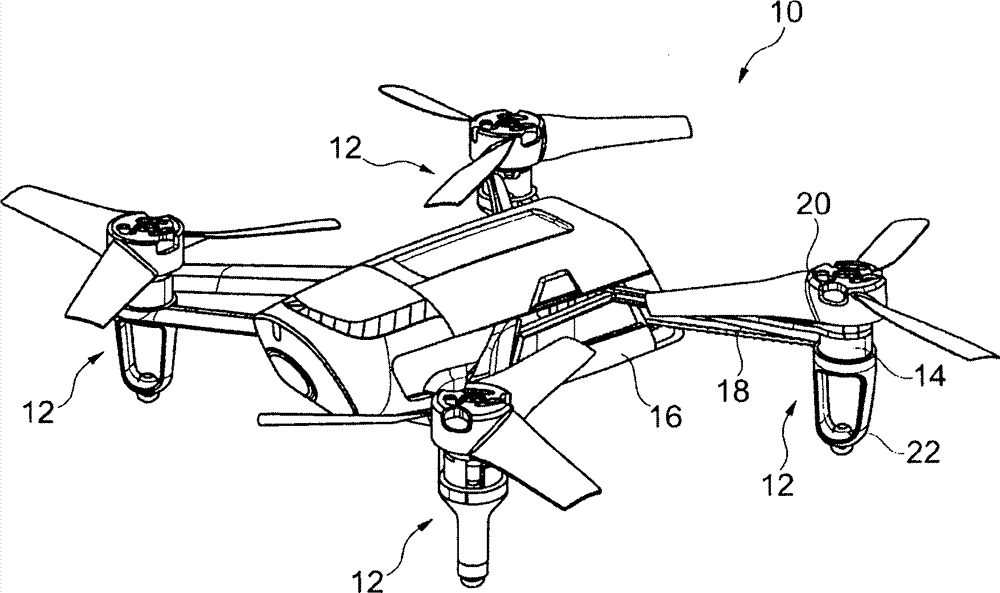

[0031] exist figure 1 In , reference numeral 10 generally denotes an unmanned aircraft of the quad-propeller helicopter type having four propulsion systems 12 . Each propulsion system 12 includes a fixed portion 14 housing a drive motor and connected by brackets 18 to a fuselage 16 of the drone. The motor of each propulsion system drives in rotation a respective propeller 20 extending in an approximately horizontal plane above the fixed part 14 and support 18 . In the bottom position, the propulsion unit is extended by a stirrup 22 to form a base by which the drone can be supported on the ground.

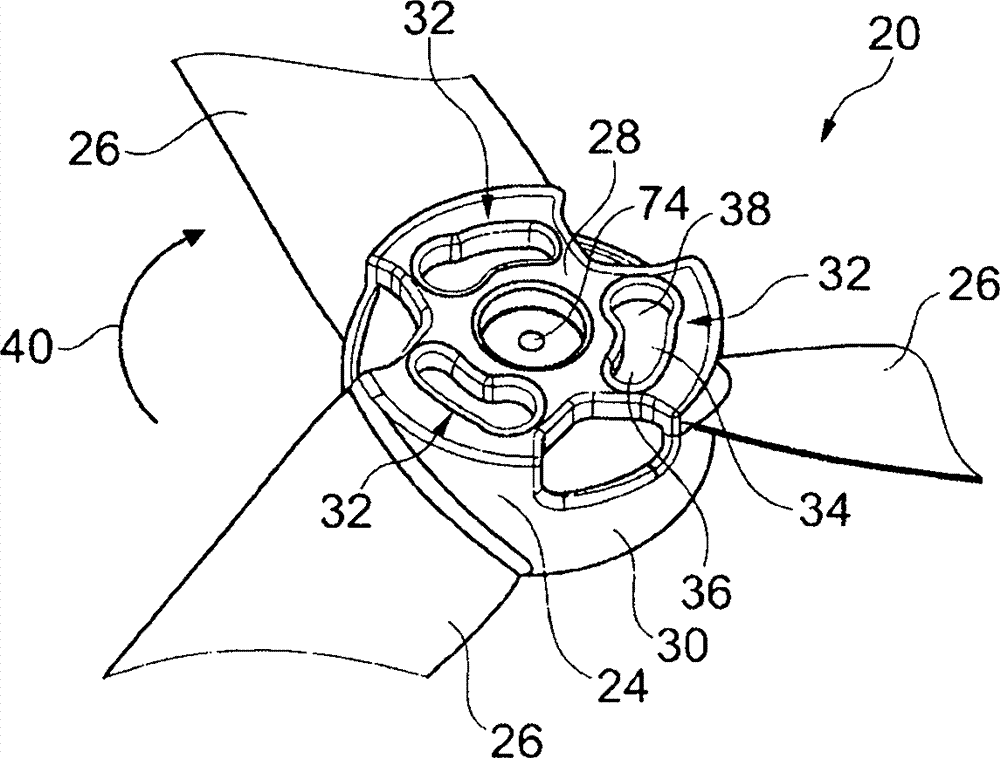

[0032] figure 2 Shows a perspective view of the central part of the propeller of an unmanned aircraft according to the invention, shown in fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com