Semi-automatic electromagnetic riveting device of conical-tubular-structure workpiece

A semi-automatic and electromagnetic riveting technology, which is applied in the field of electromagnetic riveting devices, can solve the problems of difficult riveting and poor practicability of workpieces with conical cylindrical structures, and achieves the effects of good practicability, convenient adjustment, quick clamping and fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

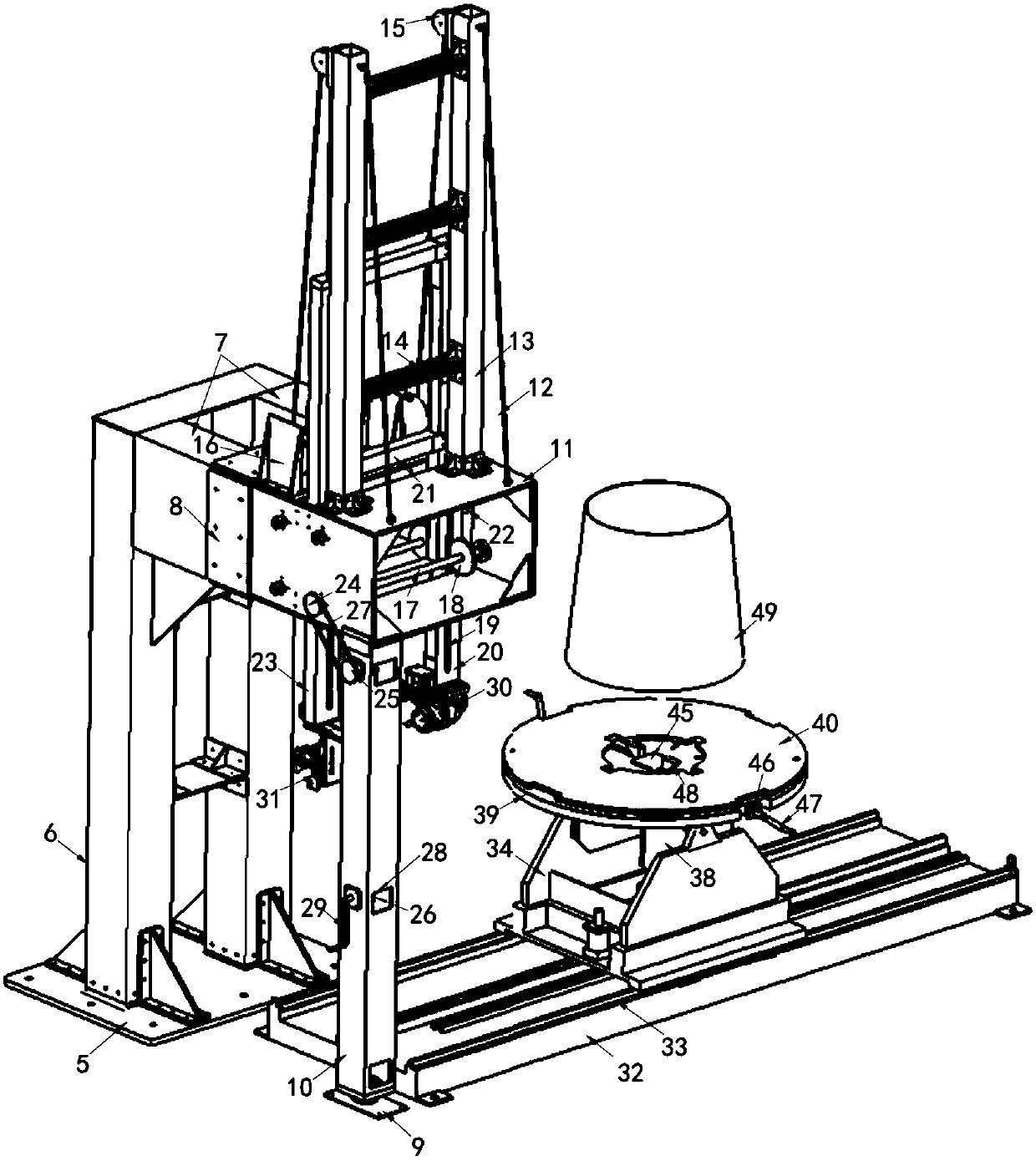

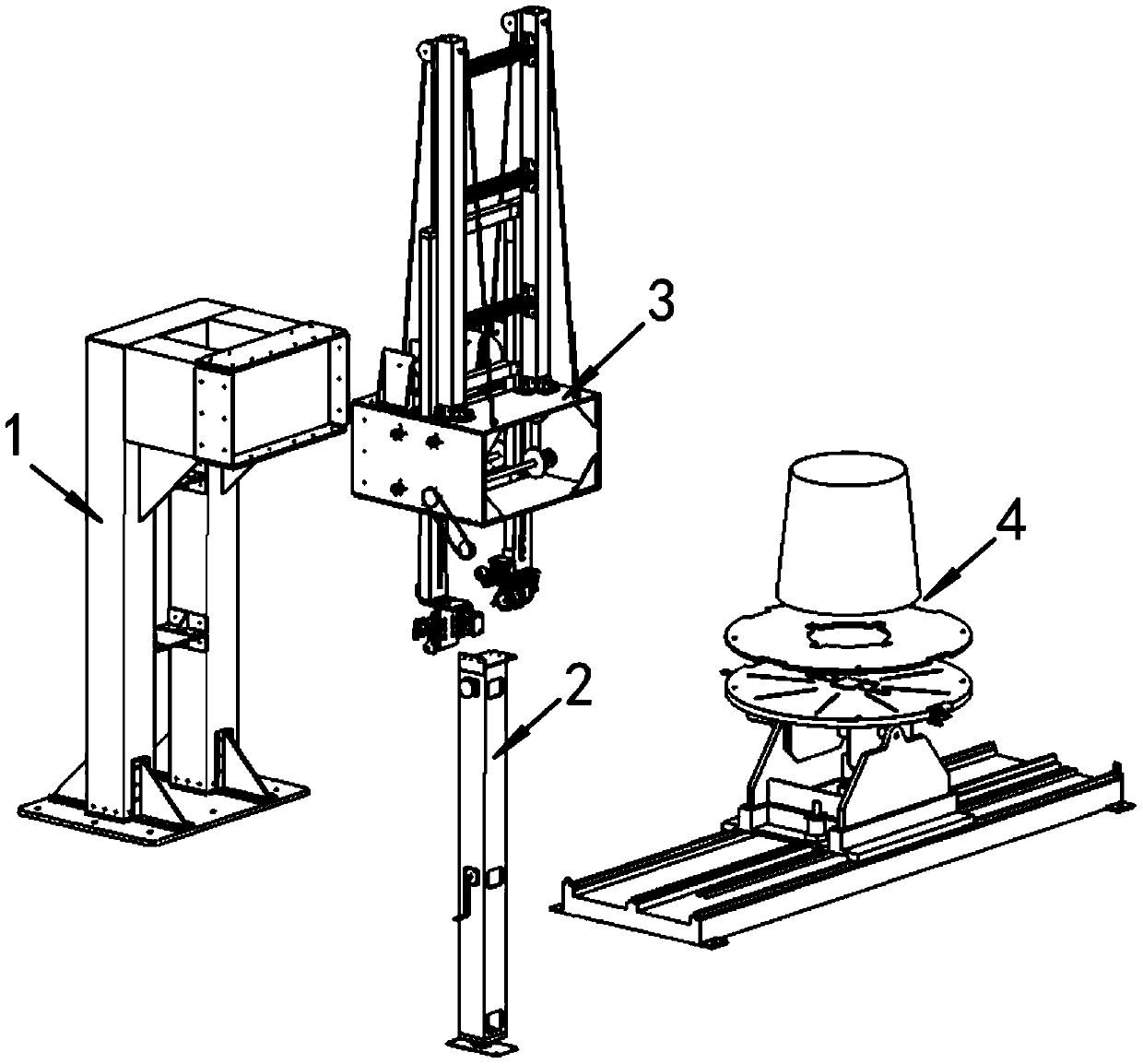

[0017] The following examples refer to Figure 1-6 .

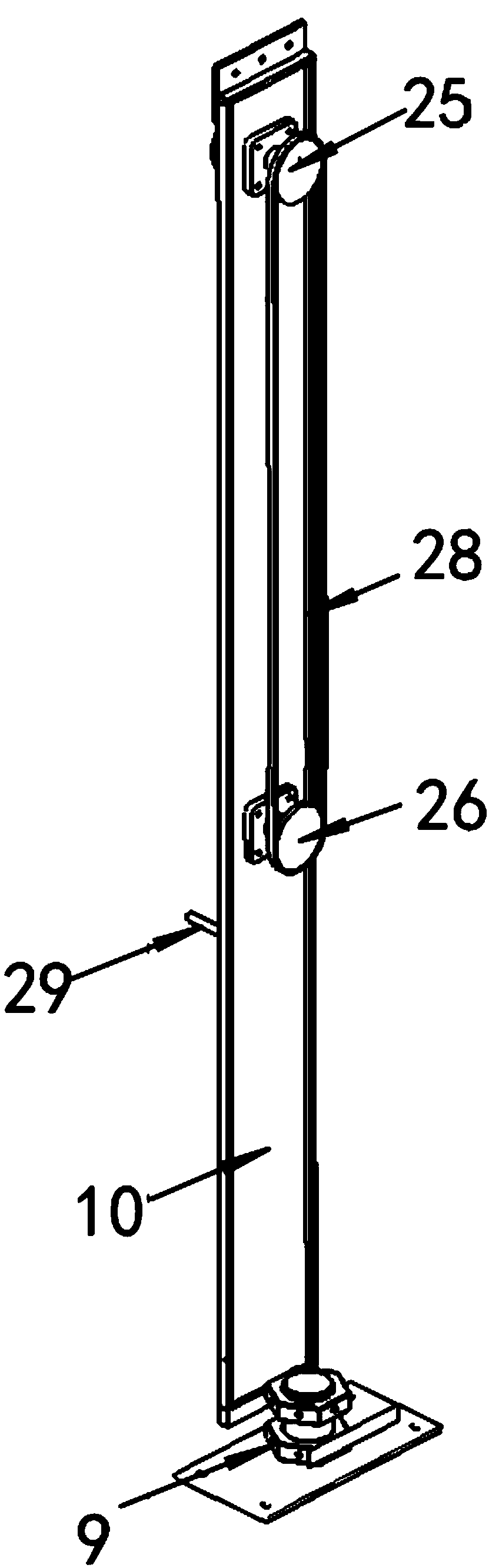

[0018] The semi-automatic electromagnetic riveting device for conical cylindrical structural parts of the present invention includes a fixed support frame 1 , a support column assembly 2 , a riveting execution assembly 3 and a positioner assembly 4 . The crossbeam 7 of the fixed support frame 1 is fixedly connected with the fixed box 11 of the riveted executive assembly 3 through the connecting plate 8, and the bottom plate 5 of the fixed support frame 1 is fixed on the foundation by anchor bolts to play a role of fixed support; the support column assembly 2 The supporting column 10 and the fixed box 11 of the riveting executive assembly 3 are connected by bolts, the lower end of the supporting column assembly 2 is fixed on the foundation through the adjustable base 9 of the supporting column, and the level of the fixed box 11 is ensured by adjusting the supporting height; the riveting executive assembly 3 Ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com