Clamping weighing device for car damper

A technology of weighing device and clamping device, applied in static weighing. It can solve the problems that the wheel clamp and the static rail scale cannot be well matched, the depth of the dumper's foundation pit increases, and the investment cost increases, so as to achieve the effect of light weight, compact structure and improved operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

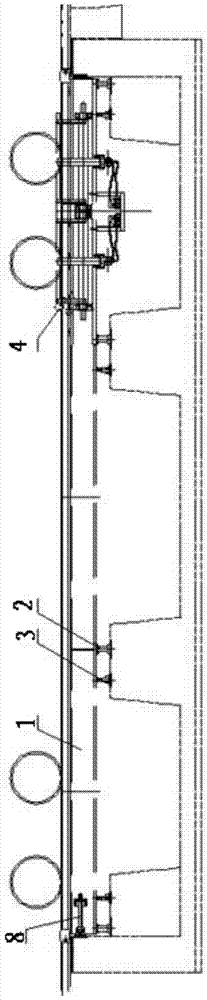

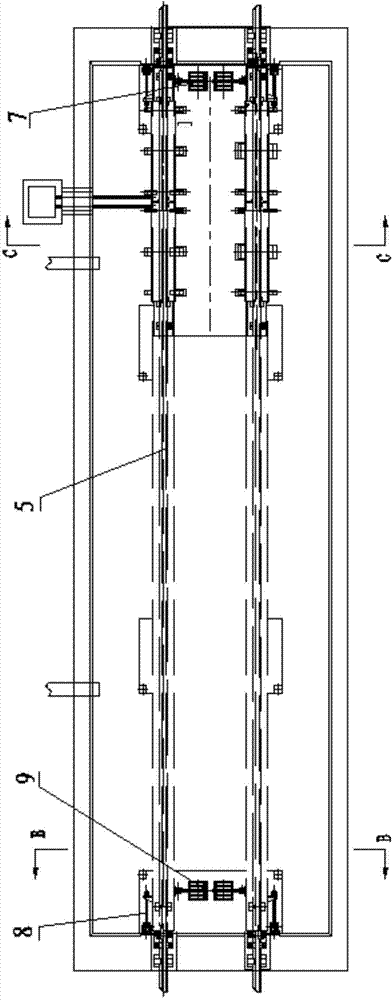

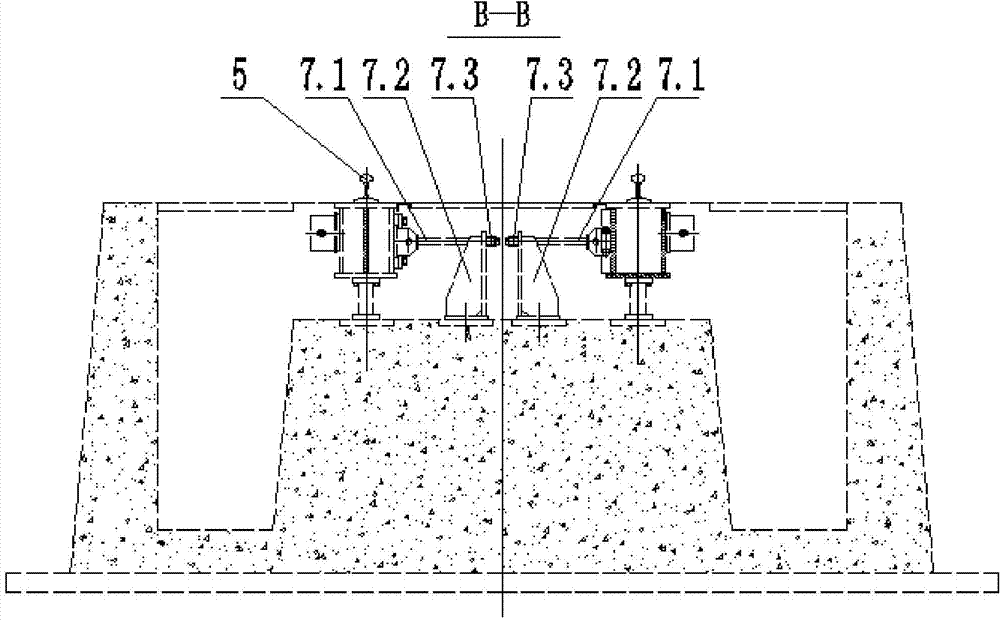

[0024] The embodiment is a clamping and weighing device for a dumper with four transverse tensioning devices 7 and four longitudinal tensioning devices 8 . As shown in the attached picture.

[0025] The clamping and weighing device for the dumper is set on the railway track at the entry end of the dumper. The gondola car first passes through the weighing device and then enters the dumper for dumping. The weighing device includes a platform 1, a pressure sensor 2, a clamping device 4, a lateral Tensioning device 7 and longitudinal tensioning device 8; platform 1 is an integral platform of steel structure, on which platform 1 is provided with running track 5 of a railway gondola car, running track 5 is placed on the track beam of platform 1, and foundation pit is set under platform 1; The pressure sensor 2 is connected to the data processing instrument through a signal l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com