Glass-welded convex low-altitude glass by glass welding with edge sealed by sealing grooves and strips and production method thereof

A low-altitude glass, sealing strip groove technology, applied in glass forming, glass re-forming, glass manufacturing equipment and other directions, to achieve high sealing strength and air tightness, eliminate variable deformation, eliminate the effects of edge sealing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

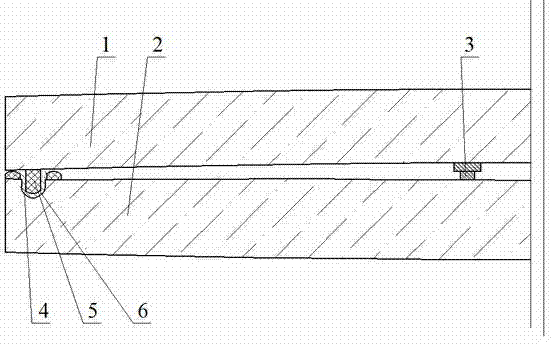

[0034] Example: see figure 1, The convex low-altitude glass is composed of an upper glass 1 and a lower glass 2, the peripheries of the two pieces of glass are welded together by glass solder 4, and the middle is a low-altitude layer. Its production method is as follows: first, cut two flat glasses of required size according to the shape and size of the convex low-altitude glass produced, set up a sealing groove 6 at the peripheral welding place of the lower glass 2, and perform edging, chamfering, cleaning, and drying. Use mechanical spraying technology to prepare the sealing strip 5 at the peripheral welding place of the upper glass 1 and the periphery of the sealing groove of the lower glass, and prepare the support 3 on the upper and lower glass with a glue dispenser; In the furnace, heat up to the softening temperature of the glass at 550-750°C, rely on the gravity of the glass itself to make the glass downwards to form a convex surface, and then cool down to room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com