A device for semi-coke CDQ and waste heat utilization of rotary kiln dry distillation powder

A rotary kiln and semi-coke technology, which is applied in the direction of unloading device, waste heat treatment, coke cooling, etc., can solve the problems that cannot meet the requirements of rotary kiln dry distillation semi-coke, small production capacity, etc., and achieve favorable manufacturing, thermal conductivity and thermal resistance The effect of large and reduced heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

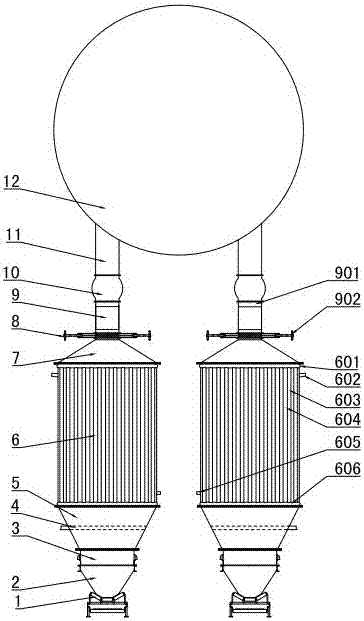

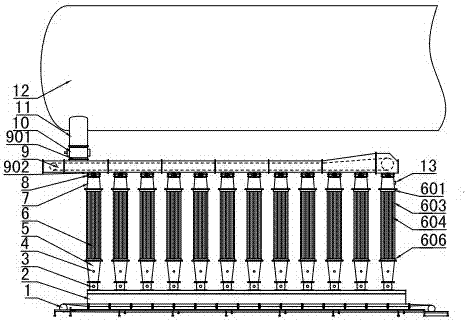

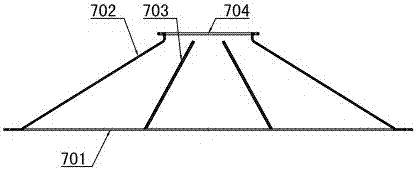

[0021] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~3 The present invention will be further described.

[0022] Refer to attached Figure 1-2 : A device for blue carbon CDQ and waste heat utilization of rotary kiln dry distillation powder, including two high-temperature unloading valves 10, two high-temperature-resistant scraper conveyors 9, twenty-four screw gates 8, and twenty-four fabrics 7, twenty-four heat exchangers 6, twenty-four water-cooled jackets 5, twenty-four discharge valves 3, two conveyors 1 and level detectors 13. A high-temperature discharge valve 10 is respectively provided at the lower ends of the two discharge pipes 11 of the rotary kiln 12, and the lower end of each high-temperature discharge valve 10 is tightly connected with a feed port 901 of a high-temperature-resistant scraper conveyor 9 and connected. Twelve outlets 902 are evenly spaced at the bottom of each high-temperature-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com