Knitting Method Of Braided Fabric And Manufacturing Method Of Braided Fabric

A technology of braided fabrics and fabric parts, which is applied in the field of braided fabrics and braided fabrics, which can solve the problems of poor workability in setting operations and achieve the effect of easy setting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

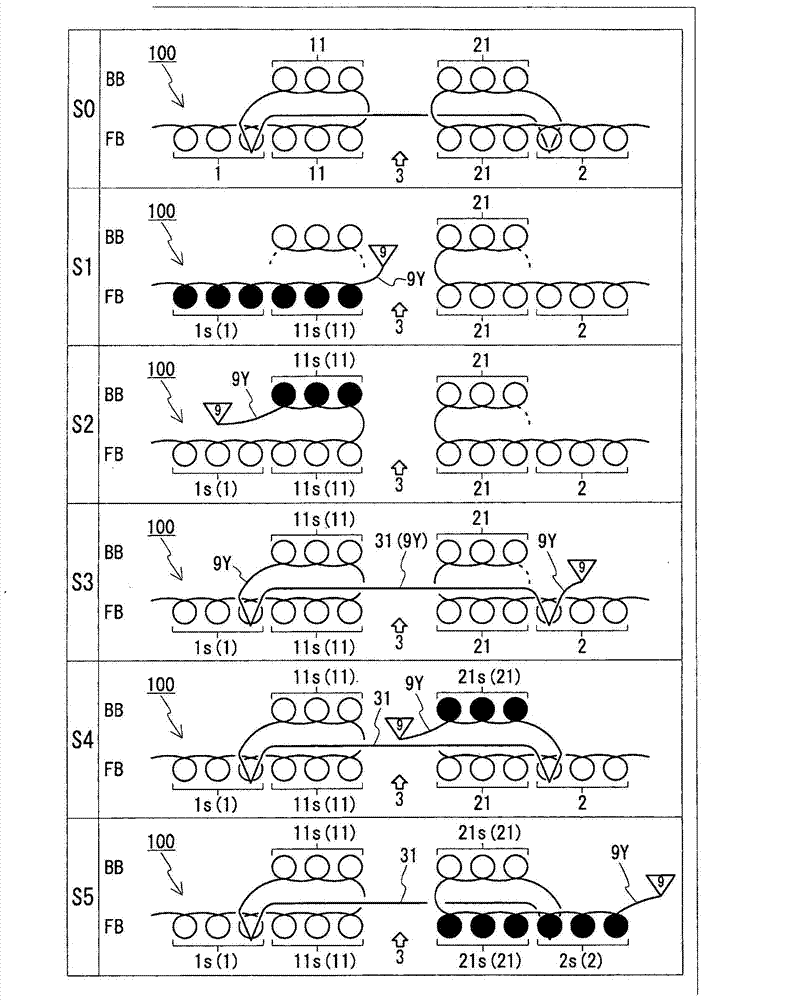

[0029] "the whole frame"

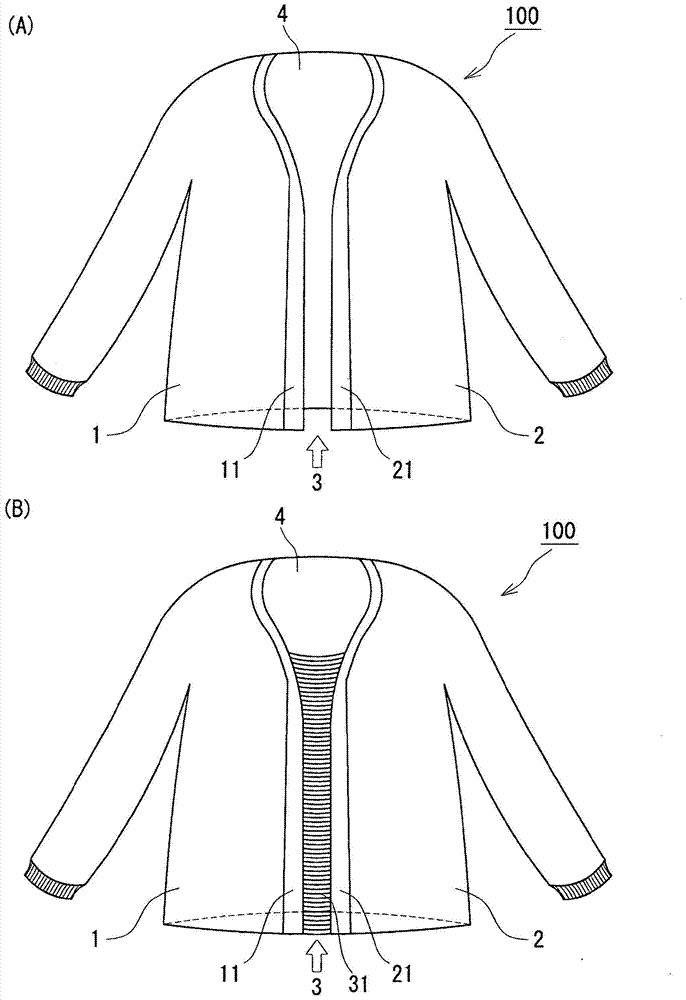

[0030] In Embodiment 1, it is explained that figure 1 Production example of the cardigan (knitted fabric) 100 shown in (A). This cardigan 100 includes a right front garment part (first knitted fabric part) 1, a left front garment part (second knitted fabric part) 2, and a rear garment part 4. A spacer 3 is formed between the 2. Moreover, a bag-shaped right side edge (first edge) 11 is formed at the end of the partition 3 side of the right front garment part 1, and a bag-shaped right edge (first edge) 11 is formed at the end of the partition 3 side of the left front garment part 2. Left edge portion (second edge portion) 21 .

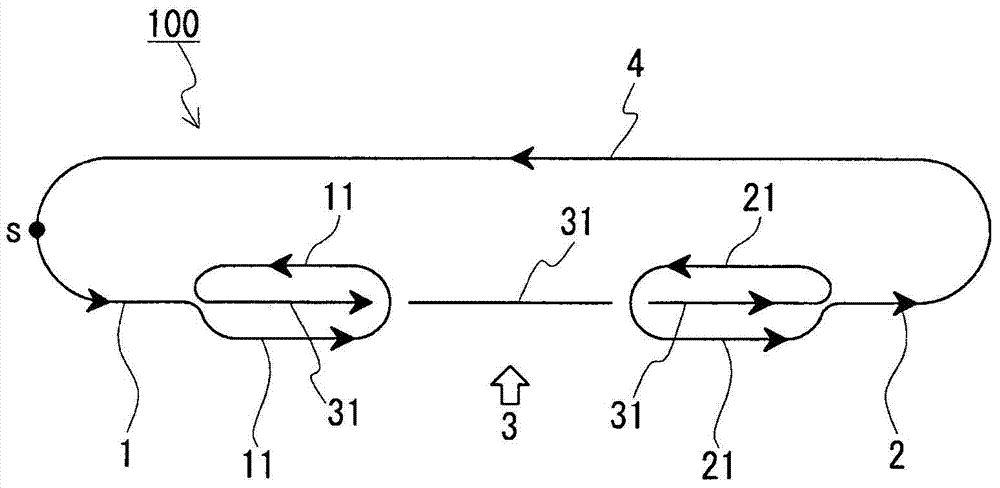

[0031] figure 1 (A) cardigan 100 through pair with figure 1 The cardigan 100 woven in the state shown in (B) is processed (which processing will be described later). figure 1 (B) Cardigan 100 with figure 1 The cardigan 100 of (A) is different in that, in the partition part 3 including the neck opening, the position corre...

Embodiment approach 2

[0055] Utilize the weaving method of braided fabric of the present invention, can weave such as Figure 4 Shown is a vest 101 with a partition 3 formed between the right front 1 and left front 2 panels. Best with Embodiment 1's image 3 The overlapping yarn portion (not shown) in the partition portion 3 is formed in the same manner.

[0056] Here, armholes are formed in the vest 101 . The armhole can be regarded as a partition 3 formed between the front panels 1 and 2 and the rear panel 4 arranged in the front and rear. Therefore, it is also possible to form a lapping yarn portion in the armhole, and connect the front garment parts 1, 2 and the rear garment part 4 by the lapping yarn part. exist Figure 5 shown in Figure 4 An example of the knitting sequence of the sections shown by the double-dashed lines. Figure 5 The observation method is the same as that of Embodiment 1 figure 2 same.

[0057] in the Figure 5 In the case of "s" as the starting point, it is pos...

Embodiment approach 3

[0060] In Embodiments 1 and 2, an example of knitting a tubular knitted fabric was described. In contrast, in Embodiment 3, based on Image 6 A knitting example of a single-layer knitted fabric having a partition will be described.

[0061] Image 6 This is a schematic diagram of the cardigan 100 knitted in a planar unfolded state. This cardigan 100 is a single-layer knitted fabric obtained by knitting from the hem side of the front parts 1 and 2 and finishing knitting at the hem side of the back part 4 . In this cardigan 100, the front parts 1 and 2 are knitted while forming the overlapping yarn part 31 at the open part 3. In this case, it is preferable to alternately repeat [1] and [2] shown below.

[0062] [1] Knitting for one course is performed in the order of right front part 1→right edge part 11→lapping yarn part 31→left edge part 21→left front part 2.

[0063] [2] Knitting for one course is performed in the order of left front part 2→left edge part 21→lapping yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com