Lifting platform system for placing large caisson in water

A lifting platform and platform technology, applied in caissons, buildings, infrastructure engineering, etc., can solve the problems of huge cost, large draft area, and high risk of anchoring and positioning, so as to improve safety, reduce prefabrication and transportation costs, The effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

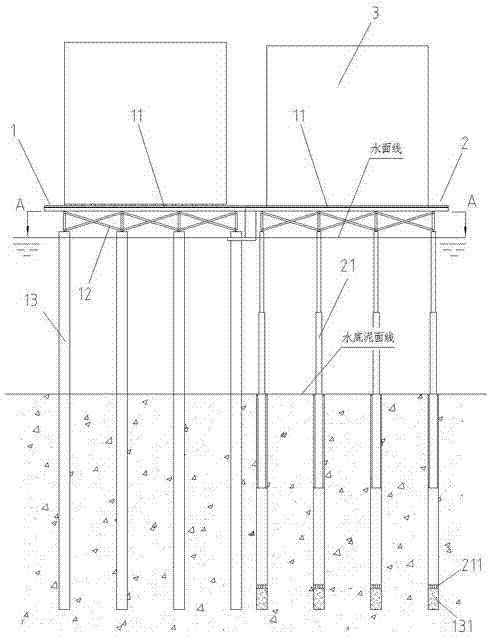

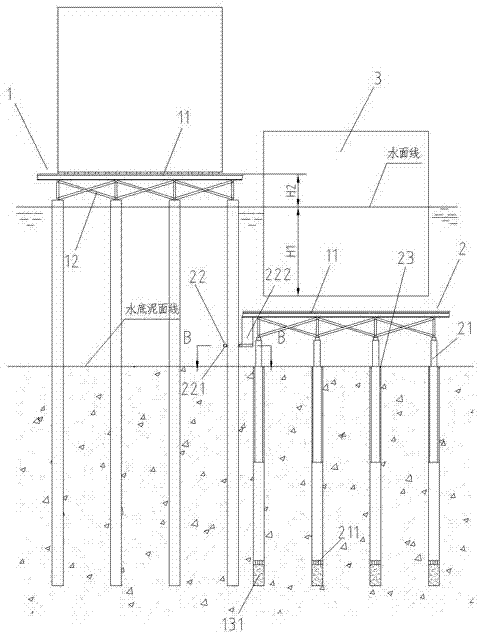

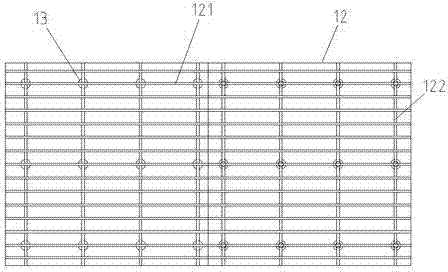

[0019] Such as Figure 1 to Figure 4 As shown, the present invention includes several prefabricated platforms 1 and lifting platforms 2 supported in water, and several prefabricated platforms 1 are spliced into a platform wharf, and its quantity is determined according to the required length of the platform wharf. The left side of the lifting platform 2 leans against the prefabricated platform 1 limit of the platform wharf, and the two adjacent sides of the prefabricated platform 1 and the lifting platform 2 are all inclined to reduce the seam between the two and facilitate the movement of the large caisson 3. The top structures of the prefabricated platform 1 and the lifting platform 2 are the same. From top to bottom, there are panels 11 and grid-structured truss beams 12. The truss beams 12 include multiple longitudinal beams 121 and multiple cross beams 122 th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap