Rotary fall type flush toilet

A toilet and swivel-type technology, which is applied in flush toilets, water supply devices, buildings, etc., to achieve the effects of rapid drainage, enlarged flushing area, and concentrated water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below through examples, and the purpose is only to better understand the contents of the present invention. Therefore, the examples given are not intended to limit the content of the present invention.

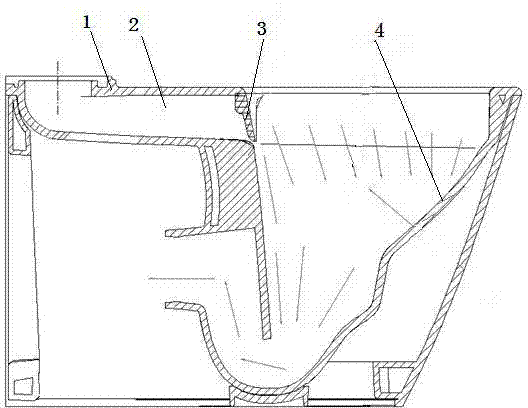

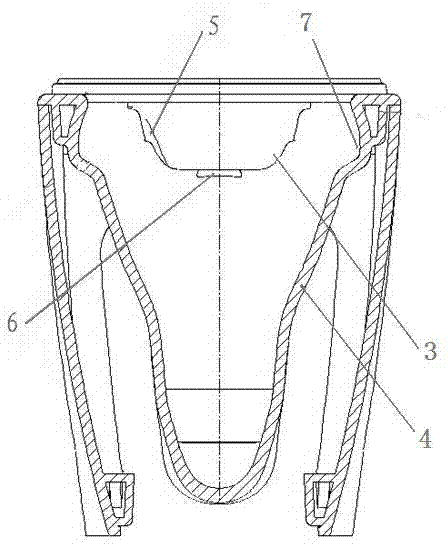

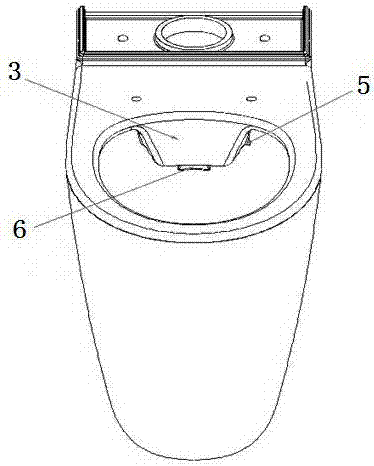

[0021] Referring to the accompanying drawings, the toilet main body 1 is the supporting body of the pot body 4 and the water tank. The inside of the toilet main body 1 is provided with a main water channel 2 connected to the water tank at the position above the rear end. The main water channel 2 is connected with the pot in the toilet main body 1 The inner cavity of the body 4 is connected with a water diversion plate 3, and three gaps are formed between the water diversion plate 3 and the surface of the pot body 4, that is, the gap 5 on both sides and the gap 6 at the bottom, wherein the cross-sectional area of the gap 5 on both sides is 1800 ~2300 square millimeters, the cross-sectional area of the bottom gap 6 is 2300~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com