Electromagnetic Insert Type Concrete Vibrator

A plug-in, concrete technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of large transmission loss, small action surface, low transmission efficiency, etc., to achieve no working noise, vibration action surface Large, no transmission loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

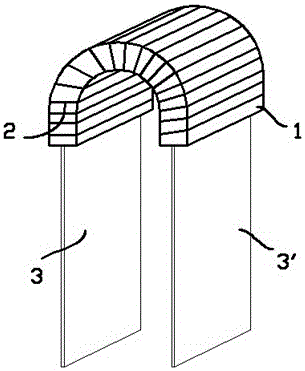

[0014] exist figure 1 In the first shown embodiment, the electromagnetic insert type concrete vibrator includes a horseshoe-shaped iron core 1, and an excitation coil 2 wound on the horseshoe-shaped iron core 1; the two magnetic poles of the horseshoe-shaped iron core 1 respectively A silicon steel sheet 3, 3' is extended downward, and the two silicon steel sheets 3, 3' are parallel to each other; the exciting coil 2 is electrically connected to an alternating power supply (not shown).

[0015] For the above-mentioned concrete vibrator, the AC power supply provides sinusoidal alternating current of 100 Hz to 200 Hz, and its frequency is basically the same as that of a traditional vibrator of 5000 r / min to 10000 r / min.

[0016] When the electromagnetic insert type concrete vibrator is working, the two silicon steel sheets 3, 3' are inserted into the concrete; since an alternating current is applied to the horseshoe-shaped iron core 1, the magnetic pole direction of the horsesho...

Embodiment 2

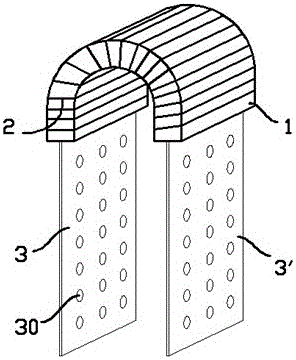

[0018] figure 2 Shown is the second embodiment of the electromagnetic insert type concrete vibrator, which differs from the first embodiment in that: the silicon steel sheets 3, 3' are evenly distributed with through holes 30 on the surface; During the vibration process of the silicon steel sheet 3, 3', the concrete near the surface of the silicon steel sheet can flow on both sides of the silicon steel sheet through the through hole 30 when being squeezed by the silicon steel sheet, thereby avoiding the deformation of the silicon steel sheet. After the silicon steel sheet is pulled out, the concrete leaves a sheet socket.

Embodiment 3

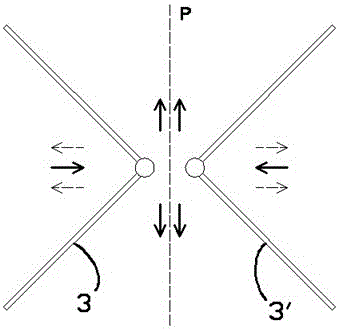

[0020] image 3 The bottom view of the silicon steel sheet 3, 3' in the shown embodiment three of the vibrator is different from the silicon steel sheet in the first embodiment in that the silicon steel sheets 3, 3' in the third embodiment are folded at right angles plate, and the two silicon steel sheets 3, 3' are symmetrical with respect to the symmetry plane P of the horseshoe-shaped iron core, and the two silicon steel sheets open angle outward and face away from each other.

[0021] According to the scheme of embodiment three, when the two silicon steel sheets 3, 3' are attracted to each other and approach each other, the outer surface of the opening angle of the silicon steel sheet just pushes outward the concrete in the direction perpendicular to the displacement direction of the silicon steel sheet; during this process , the moving direction of the silicon steel sheet and its pushing direction to the concrete are as follows: image 3 Indicated by the solid arrow.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com