Wind-sorting drum lead-power machine

A drum lead and drum technology, which is applied in the field of winnowing type drum lead powder machine, can solve the problems of increasing power consumption of powder raising, many auxiliary devices, temperature control error, etc., and achieves reduction of equipment cost and power consumption, and temperature control hysteresis effect Small, the effect of reducing the cost of milling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

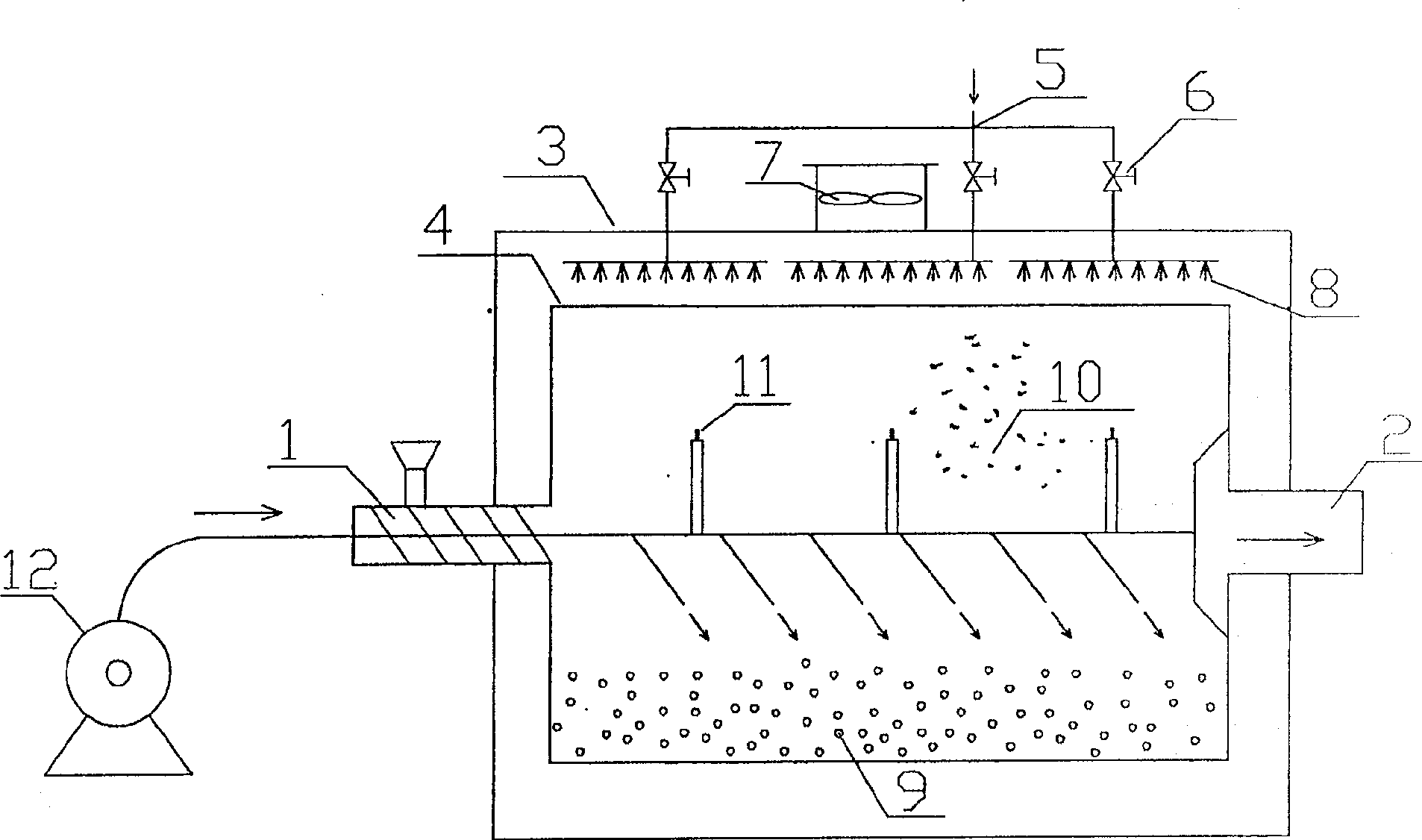

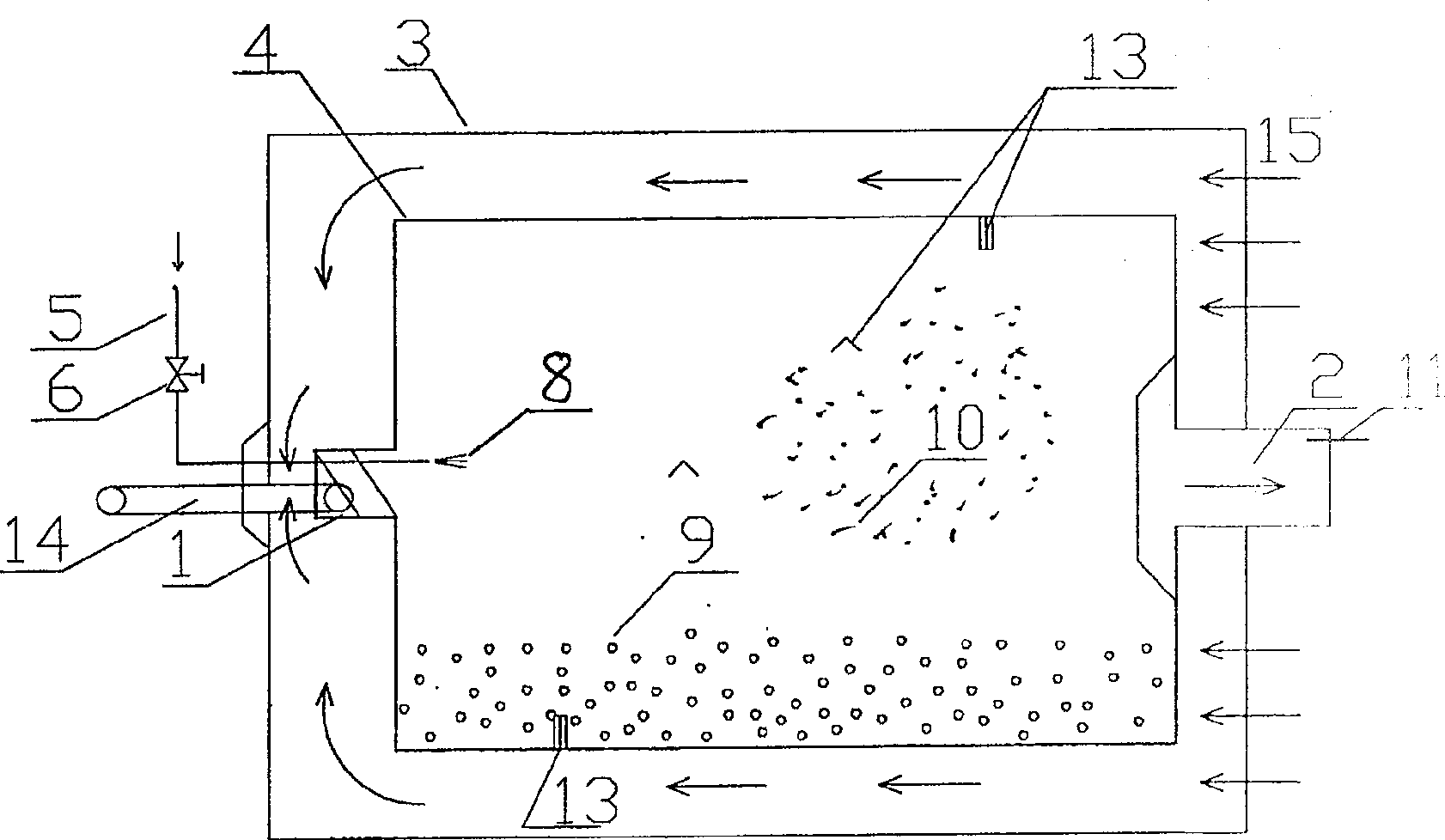

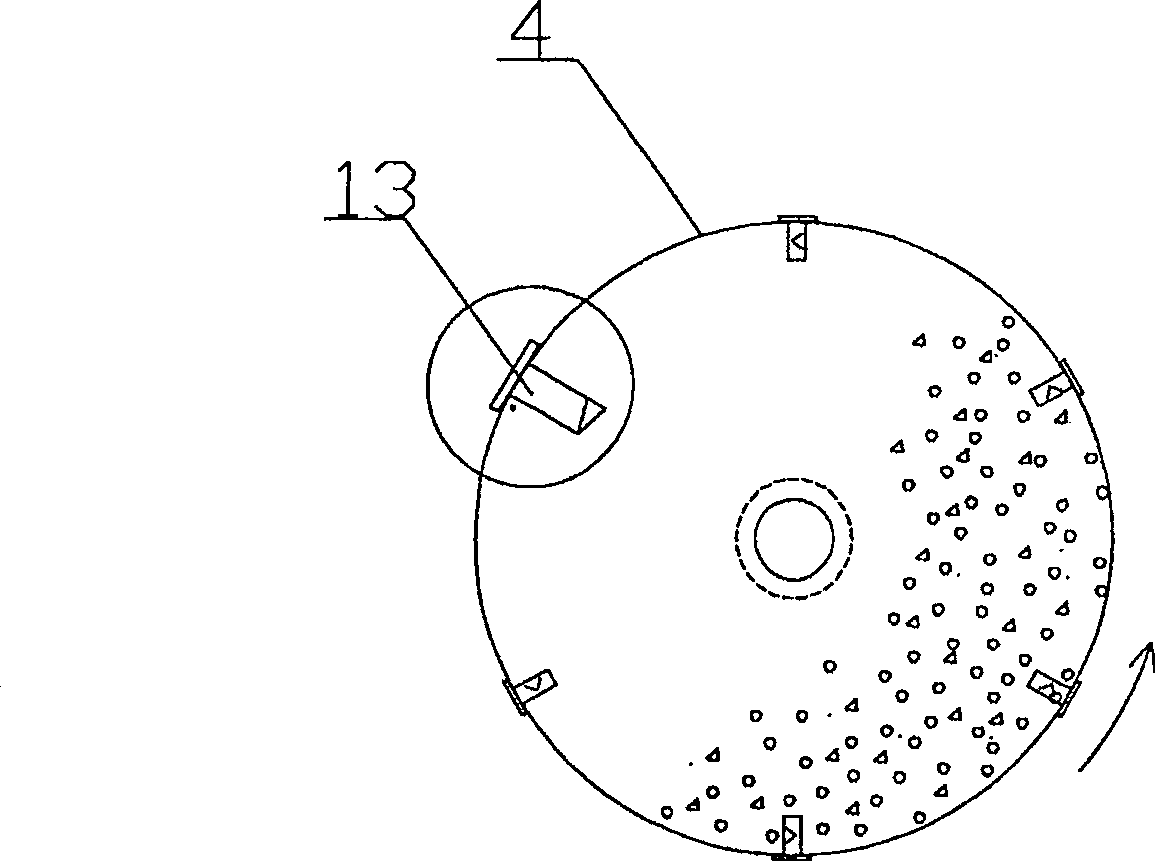

[0024] Embodiment 1: see figure 2 , 3 , air separation drum lead powder machine, comprising a rotating drum 4 and a larger fixed outer casing 3 with interlayer space, the drum feed and air inlet 1 are located in the interlayer space, and one end of the feed inlet axially extends into the drum feed inlet, One end protrudes from the circulating feeding belt 14 outside the casing to continuously deliver lead pellets 9 to the rotating drum, and an air inlet 15 is provided on the discharge end surface of the casing. The cooling water spray nozzle 8 extends from the outside of the casing to the drum 4 in the axial direction through the feeding and air inlet 1, the cooling water 5 is controlled by the valve 6, and the other end of the drum protrudes out of the casing and the exhaust outlet 2 is equipped with a temperature measuring Device 11. The inner surface of the drum 4 is axially and radially uniformly arranged with several radially protruding conical tips facing the directio...

Embodiment 2

[0025] Example 2: see Figure 4 , as in the embodiment, wherein the lead particle feeding device is: there is an inclined blanking arc plate 16 extending into the feeding port similar to the cement mixer feeding device above the drum feeding port, and there are two blanking funnels 17 passing through the casing above the drum feeding port. or together to replace the circular feed belt.

[0026] In addition, the feed and air inlets can also be set separately; the temperature detector 11 can also be as figure 1 There are multiple settings in the drum, etc., and some insubstantial changes all belong to the protection scope of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com