Localizable drilling machine tapping fixture

A tooling and drilling machine technology, applied in the field of positioning drilling machine tapping tooling, can solve the problems of reducing production efficiency and product accuracy, and achieve the effects of improving low precision, ensuring safety, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

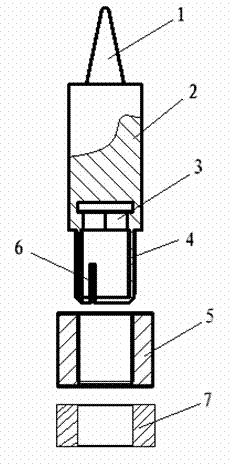

[0014] like figure 1 As shown, a tapping tool for a positionable drilling machine includes a Morse taper sleeve 1 and a tapping tap (not shown in the figure), and a clamping plate 3 is arranged in the Morse taper sleeve 1 sleeve 2, and the clamping plate 3 Cooperate with tapping taps. An adjusting screw 4 and an adjusting nut 5 are arranged at the end of the sleeve 2, and the adjusting screw 4 and the adjusting nut 5 have the same taper. The adjustment screw 4 is provided with an adjustment gap 6 . At the same time, in order to ensure the accuracy of tapping, a fixed ring 7 is arranged between the tooling and the workpiece. The fixed ring 7 is arranged coaxially with the spindle of the drilling machine. During the tapping process, the tap passes through the fixed ring 7 to determine the position of the tap. Guaranteed machining accuracy.

[0015] Specifically, the tapping tool for the drilling machine in the present invention is connected to the drilling machine through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com