A method for sintering calcium zirconate microwave dielectric ceramics at low temperature

A microwave dielectric ceramic and low-temperature sintering technology is applied in the field of low-temperature sintering calcium zirconate microwave dielectric ceramics, which can solve the problem that electrodes cannot be co-fired, and achieve the effects of improving the sintering environment, reducing the sintering temperature, and having good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

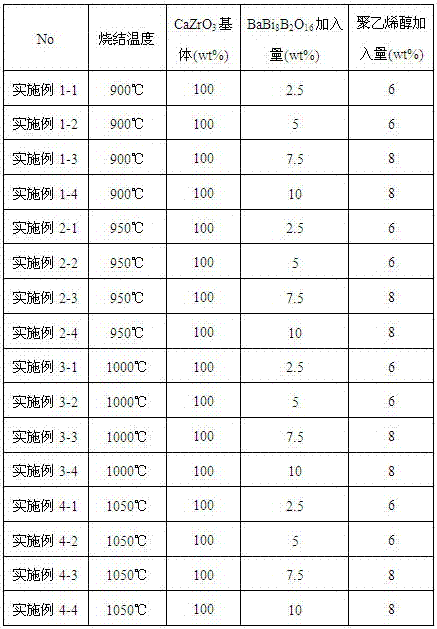

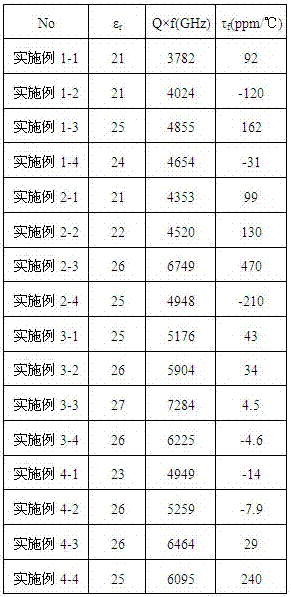

[0022] The invention is illustrated in detail in the following examples, in which all parts and percentages are by weight unless otherwise indicated.

[0023] Such as figure 1 The preparation technological process of described embodiment comprises the following processes:

[0024] Step 1. Analytical pure BaCO 3 、H 3 BO 3 、 Bi 2 o 3 Powder by mass ratio m (BaCO 3 ) : m (H 3 BO 3 ) : m (Bi 2 o 3) = 1:4:2 ratio to make a mixture, put it into a nylon ball mill tank, and press BaBi respectively 8 B 2 o 16 180~200% and 150~160% of the weight of the mixture are added with zirconia balls and absolute ethanol as ball milling aids, and ball milled in a planetary ball mill for 8~12 hours at a speed of 200~220r / min; The slurry is dried in a drying oven at 120°C for 8 hours; the dried mixture is ground in an agate jar, and the ground mixture is passed through a 120-mesh standard sieve; the sieved mixture is put into a corundum crucible , and then placed in a muffle furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com