A horizontal self-locking assembled wall panel and its construction method embedded in a building wall

A self-locking, horizontal technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of poor earthquake resistance and the inability to install wall tie bars, etc., to achieve good earthquake resistance, fast and convenient assembly construction, and enhance integrity and the effect of shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

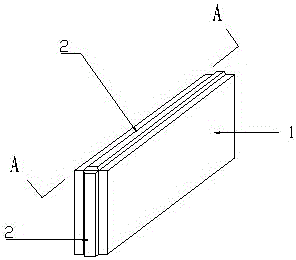

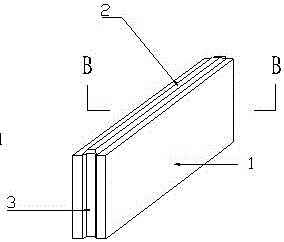

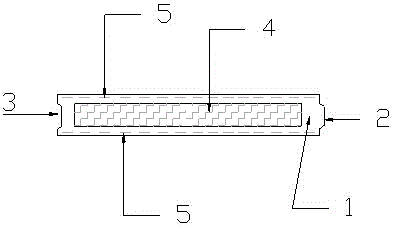

[0017] Such as Figure 1~Figure 3 As shown, a horizontal self-locking assembled wall panel and its embedded light steel keel wall structure. The specifications of horizontal self-locking assembled wall panels are: 2400×600×120 / 95 / 70; 1200×300×120 / 95 / 70. The horizontal self-locking assembled wall panel is composed of glass fiber mesh cloth (5), surface-enhanced fluid microporous lightweight concrete matrix 1 and rock wool insulation core board 4. Insulation core board 4 has a bulk density greater than 100kg / m 3 rock wool insulation board.

[0018] Fluid lightweight concrete matrix 1 uses fast-hardening cementitious materials and light aggregates (cinder, drama end) as raw materials, which are transported to the computer batching system through reamers and buckets, and then sent to the fast mixer after being weighed by the batching system , Stir the fluid special lightweight concrete into a slurry, turn it over and pour it into a special group of mold cavities. The fluid lig...

Embodiment 2

[0026] The construction of the horizontal self-locking assembled wall panel embedded in the light steel keel wall of the steel structure building is the same as the above, only the load-bearing steel bracket 8 and the light steel keel wall steel part 7 are welded or bolted to the main structure. The connection is fixed by riveting.

[0027] The two above-mentioned embodiments both form a self-insulating wall structure with light steel keels embedded in horizontal self-locking assembled panels.

Embodiment 3

[0029] When the shear wall structure system is used for external insulation construction of the building wall, 8 load-bearing steel brackets are set on the shear wall layer by layer (or 3 meters high). On the supporting eaves, the horizontal self-locking assembled wall panels 12 with thin specifications and single tenons are used to paste and assemble the thin specification single tenon, which is the form of external heat preservation. When assembling, at the same time, set the light steel keel of the wall according to the height of every three blank slabs 6. Install the light steel keel 6 horizontally on the convex and concave tenon of the horizontal self-locking assembled wall panel 12, and use the light steel keel connecting wall steel part 7 to connect and fix firmly with the shear wall with expansion bolts. The compact composite thermal insulation wall structure of the composite horizontal self-locking assembled panels outside the shear wall meets the thermal insulation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com