Patents

Literature

40results about How to "With thermal insulation and energy saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant polyurethane material as well as preparation method and application thereof

InactiveCN102464880AGood waterproof compactnessGood heat insulation and sound insulationHeat proofingSound proofingHalogenChemistry

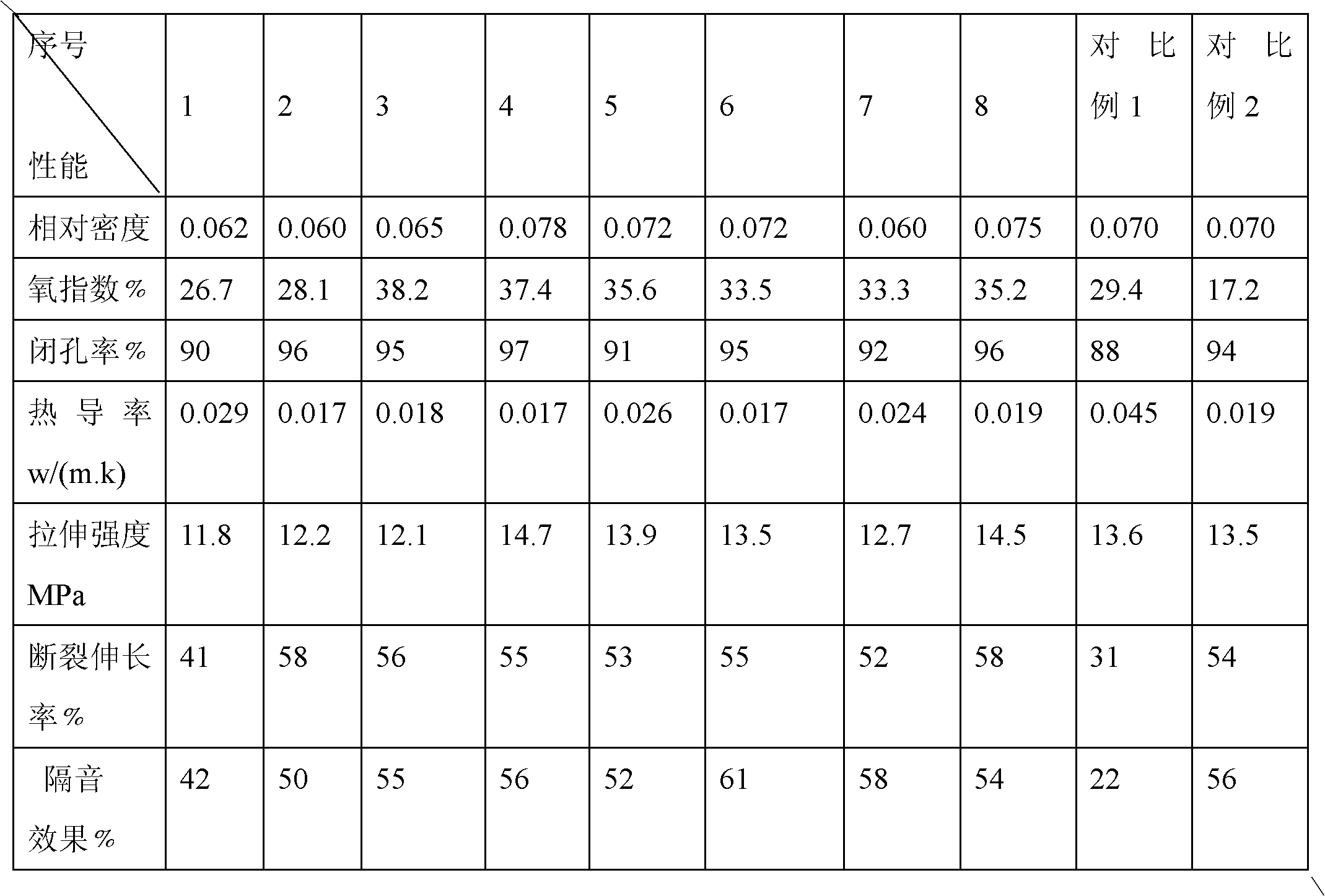

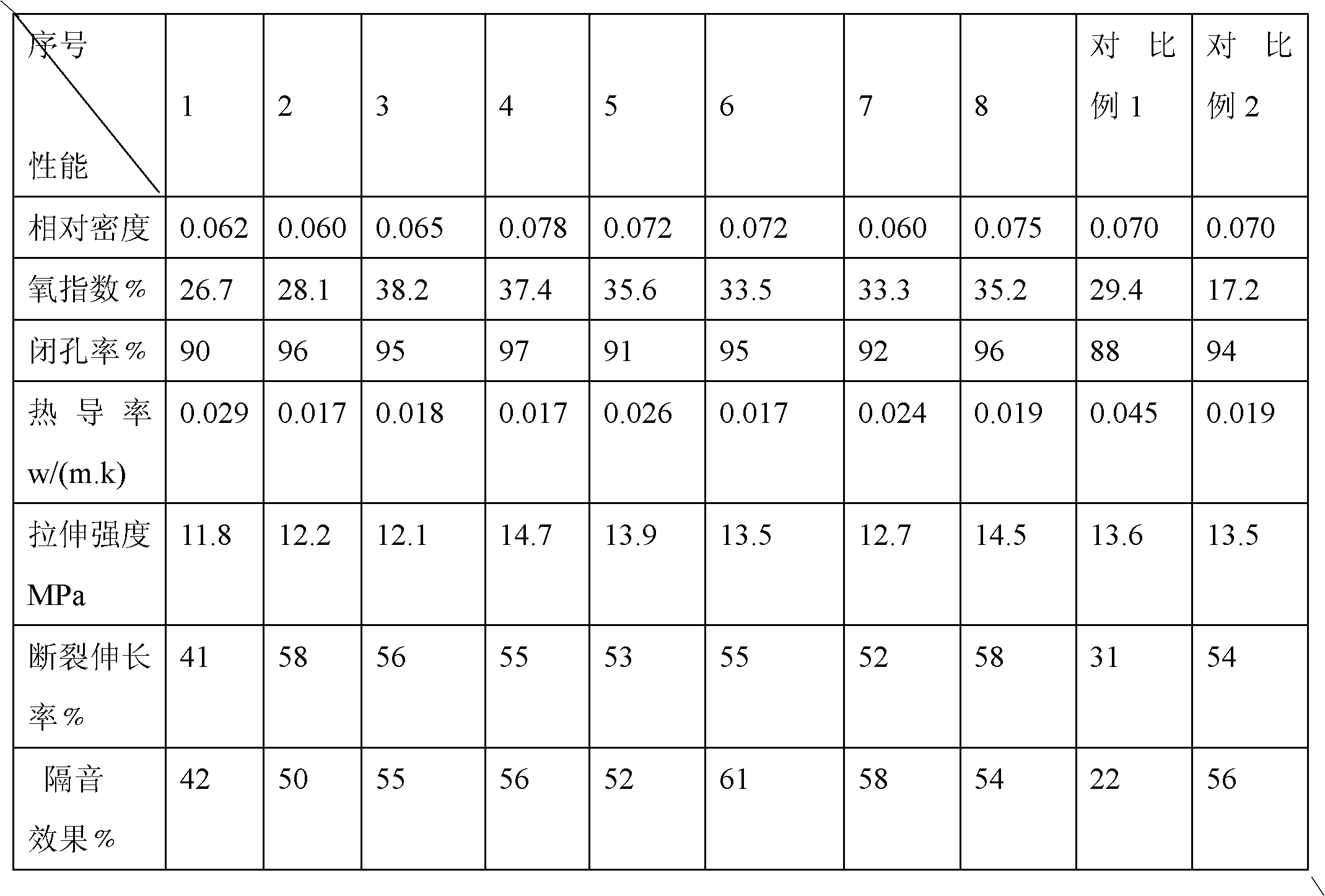

The invention belongs to the technical field of high molecular material modification and discloses an energy-saving environment friendly sound insulation flame retardant polyurethane material as well as a preparation method and application thereof. The flame retardant polyurethane material consists of the following components in parts by weight: 100 parts of polyether, 120-145 parts of polyurethane reactive monomer, 4.5-12 parts of foaming agent, 1.5-2.5 parts of foam stabilizer, 20-40 parts of polyester, 0.5-10 parts of compatilizer, 0-2.5 parts of amine catalyst, 0-2 parts of tin catalyst, 10-20 parts of fire retardant, 0-3 parts of flame retardant synergist and 10-20 parts of heat insulation and sound insulation assistant. Compared with the prior art, the energy-saving environment friendly sound insulation flame retardant polyurethane material provided by the invention is light in weight, high in strength, good in waterproof compactness, environment friendly due to no halogen, good in heat preservation, heat insulation and sound insulation effects and good in flame retardance and fireproofness up to the V-0-grade standard of UL-94 when being used as a foam building board. The material can be widely applied to various national economy fields such as the building board and the like.

Owner:GUANGXI LISHENG STONE CO LTD

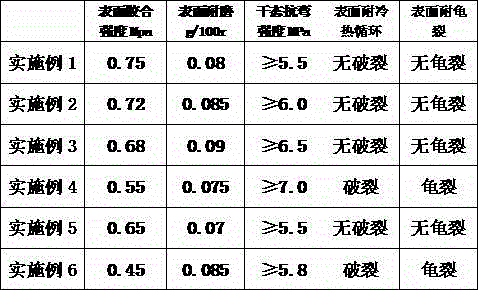

Decorative wall material diatom ooze

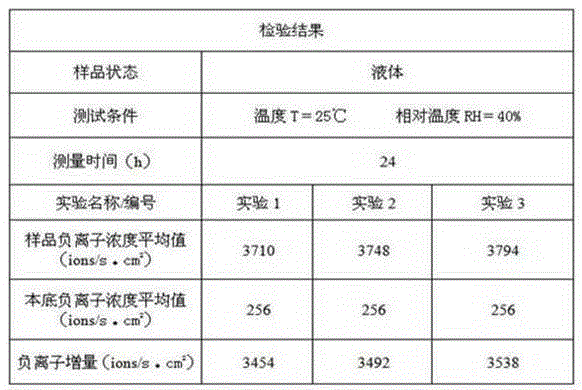

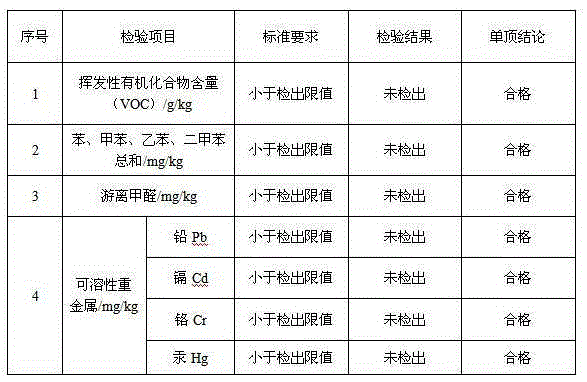

The invention discloses decorative wall material diatom ooze. The decorative wall material diatom ooze is prepared from the following raw materials: 325-mesh kieselguhr, 325-mesh talcum powder, a plant coagulant, white cement 325#, hydroxyethylmethylcellulose (HEMC), negative ion powder, a nano-photocatalyst, lignocelluloses, strain cellulose, 200-mesh coarse whiting, a dry powder defoaming agent, a dry powder retarder, titanium dioxide, mica powder, inorganic bentonite, 80 to 120-mesh snowflake white, multifunctional powder, a water reducing agent, gluconic acid sodium salt, attapulgite and bamboo charcoal powder. The decorative wall material diatom ooze is low in cost, the elimination rate and dissolution rate to formaldehyde dissociated in indoor air reach up to not less than 96 percent, and European standards and national standards are completely met; the decorative wall material diatom ooze not only has the efficacies of preventing fire and retarding inflaming, removing odor, adjusting indoor humidity and disinfecting, reducing noise and sound, insulating and saving energy, improving sleep, cleaning trash and self-cleaning and the like, but also can enable the humidity of air to be kept between 40 to 60 DEG C, the heat-insulating property of the decorative wall material diatom ooze is 2 times or above that of a current diatom ooze coating, 3400 negative oxygen ions or above can be released every second from each square centimeter, far infrared rays also can be released, and the decorative wall material diatom ooze has a healthcare function on a human body.

Owner:广东涂乐师新材料科技有限公司

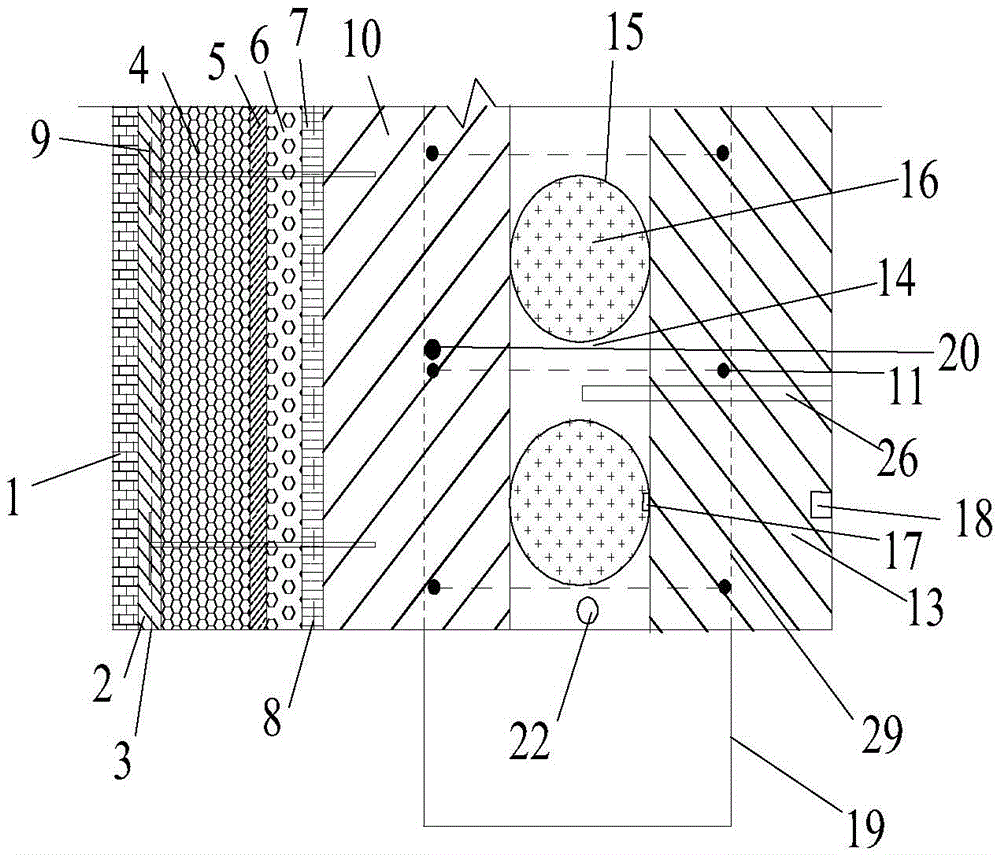

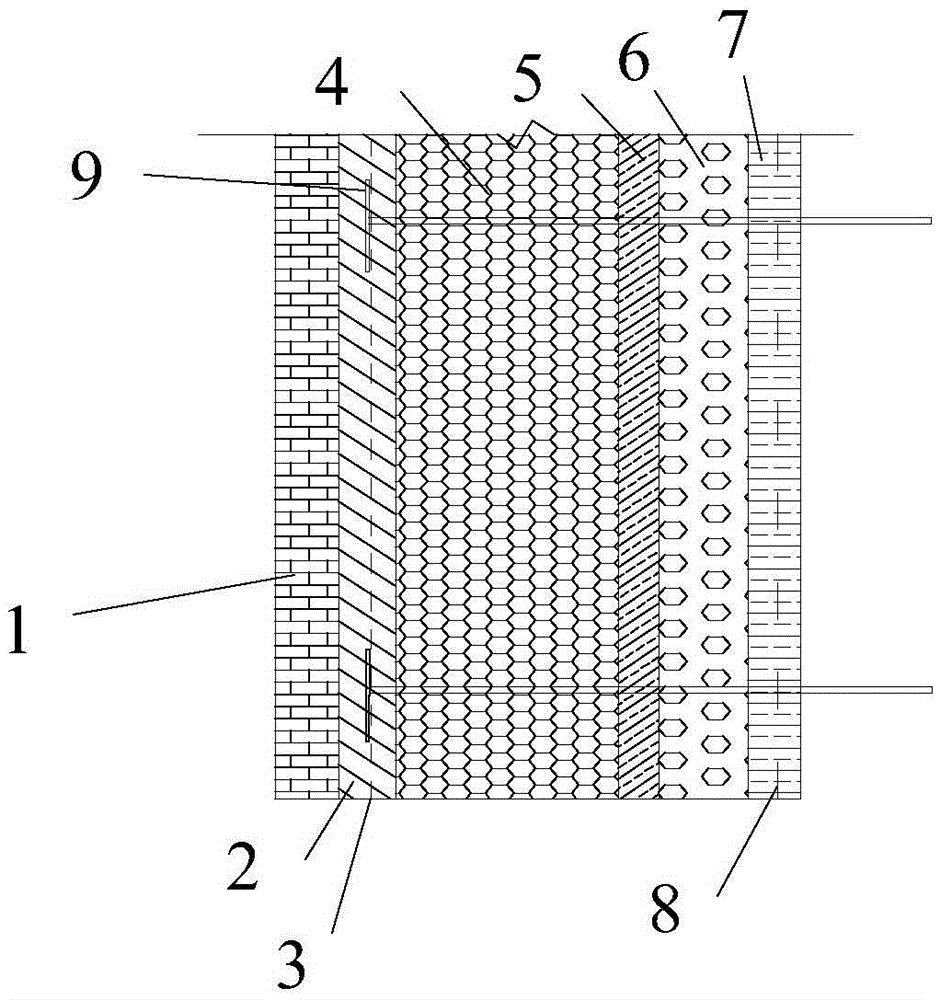

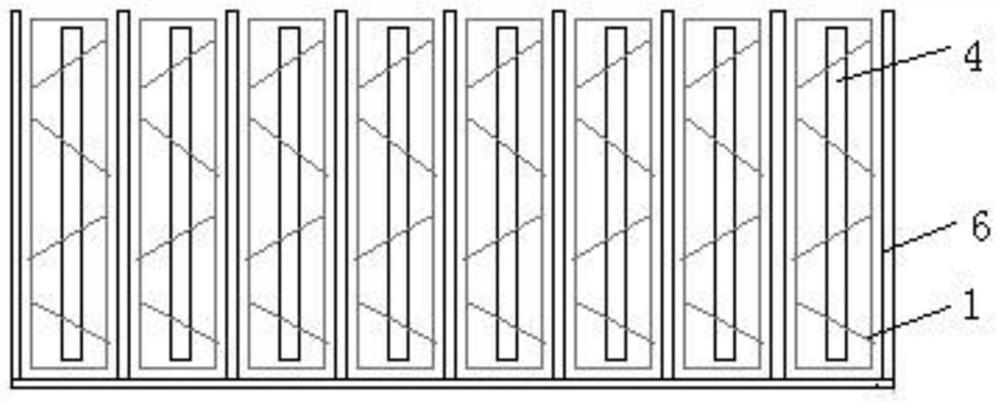

Fabricated concrete composite wallboard structure

InactiveCN105569260AImprove lateral force resistanceIncrease overturning forceBuilding componentsLine tubingWhole body

The invention provides a fabricated concrete composite wallboard structure. The fabricated concrete composite wallboard structure comprises an outer wallboard arranged towards the outside of a building, an inner wallboard arranged towards the inside of the building, and a reinforcing rib located between the outer wallboard and the inner wallboard, wherein the outer wallboard, the reinforcing rib and the inner wallboard are tied to form a whole body via a net rack; a functional compound layer is adhered to the outer surface of the outer wallboard; a part extending out of the outer wallboard, the reinforcing rib and the inner wallboard of the net rack is combined with cast-in-place concrete to form a hidden beam; a core hole used for reducing self weight of the structure is formed in the reinforcing rib along a vertical direction; a pipeline channel arranged along an axial direction of the core hole and used for laying pipelines is arranged in the core hole; and / or the core hole is also filled with core hole filling materials used for preserving heat and insulating heat; a pipeline box corresponding to the pipeline channel is pre-buried in the inner wallboard. Through type and quantity of the core hole filling materials, different heat preservation requirements in southern and northern regions are met; type and thickness of sound absorbing layers can be adjusted to meet the sound insulation requirement of the building, so that the application range of the multifunctional fabricated concrete composite wallboard is extended.

Owner:CENT SOUTH UNIV +1

Nanometer silver carbon based inner wall coating

The invention provides a nano-silver carbon silicon interior wall paint. Calcium powder and diatomite powder crushed into 300 meshes to 400 meshes of fine powder, perlite powder and active carbon powder crushed into 50 meshes to 70 meshes of fine powder are mixed and added with nano-silver and water to be blended into slurry state to form the paint. The paint of the invention utilizes the nano-silver broad-spectrum high-efficiency sterilization (virus killing) mechanism, and the coconut shell carbon and diatomite adsorption filtration energy-conservation principle to accct on the surface of the wall, and is characterized by sterilization, mold resistance, adsorption, air purification, negative ion releasing, fireproofness, fire retardation, heat preservation, energy conservation, etc., and remedies and solves all the disadvantages of traditional wall materials. The paint of the invention is applicable to the decoration and fitment of all interior walls as the wall materials.

Owner:吉林省嘉鹏硅藻土研发有限责任公司

Nanometer silver carbon based inner wall prime

The invention provides a nano-silver carbon-based interior wall basic paint. Active carbon powder crushed into 800 meshes to 1200 meshes of fine powder, calcium powder crushed into 300 meshes to 400 meshes of fine powder and pearlite powder crushed into 50 meshes to 70 meshes of fine powder are mixed and added with nano-silver, an organic adhesive and water to form the paint of the invention. The paint of the invention utilizes the nano-silver broad-spectrum high-efficiency sterilization (virus killing) mechanism, and the coconut shell carbon and diatomite adsorption filtration energy-conservation principle to act on the surface of the wall, and is characterized by sterilization, mold resistance, adsorption, air purification, negative ion releasing, fireproofness, fire retardation, heat preservation and energy conservation, etc., and remedies and solves all the disadvantages of traditional wall materials. The paint of the invention is applicable to the decoration and fitment of all interior walls as the wall materials.

Owner:NORTHEAST NORMAL UNIVERSITY

Solar water heater

ActiveCN104180535ASave energyReduce consumptionSolar heating energyConstruction materialSolar waterArchitectural engineering

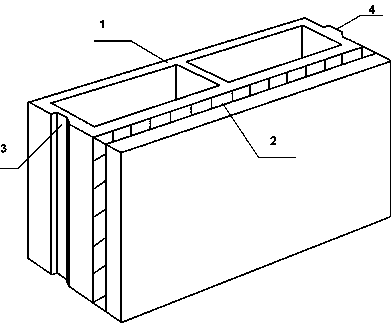

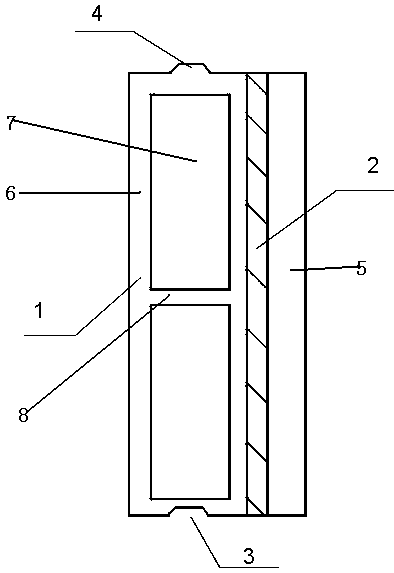

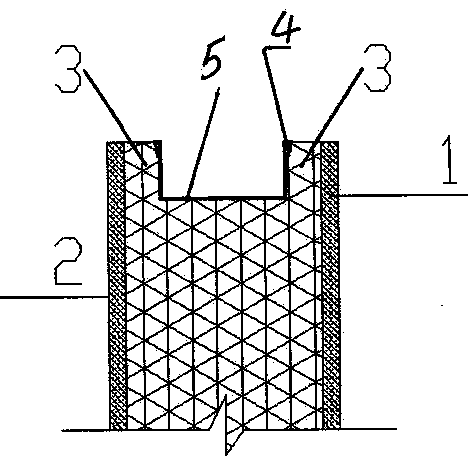

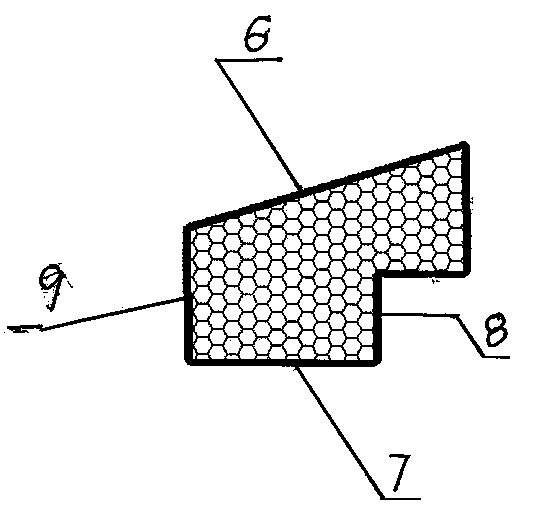

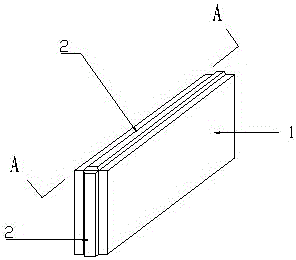

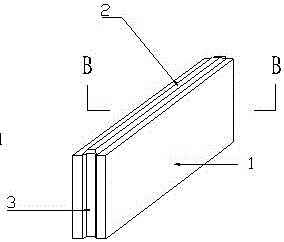

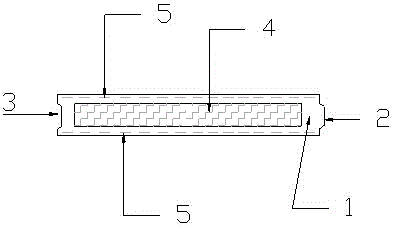

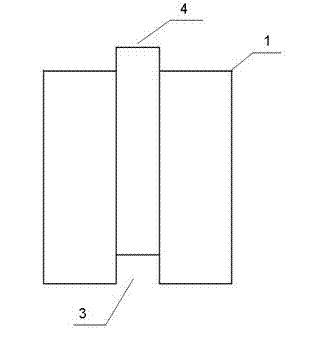

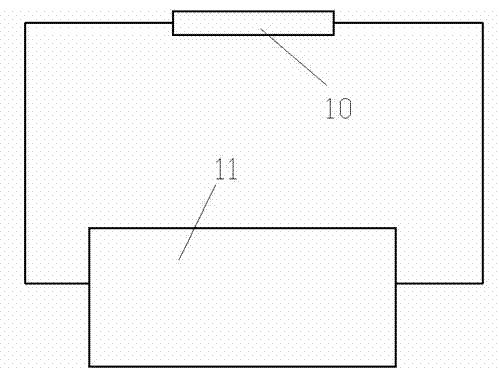

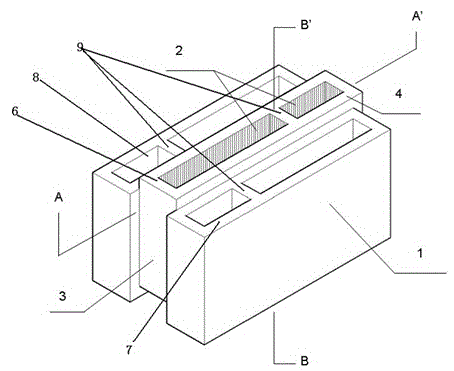

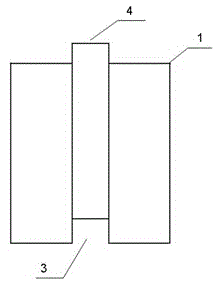

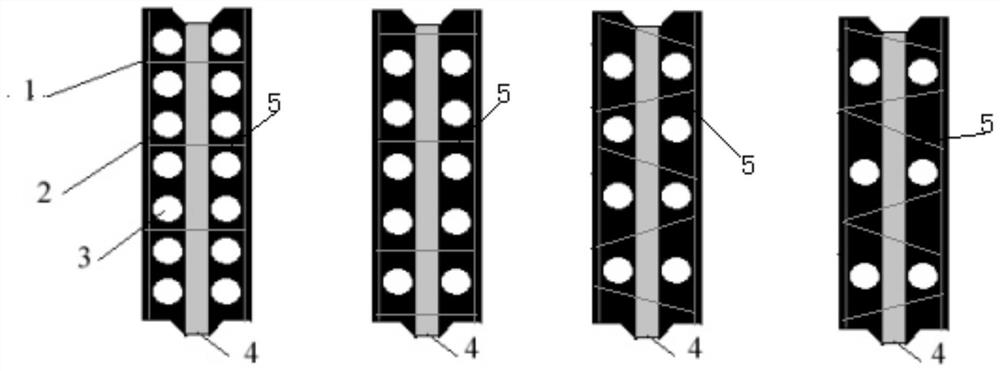

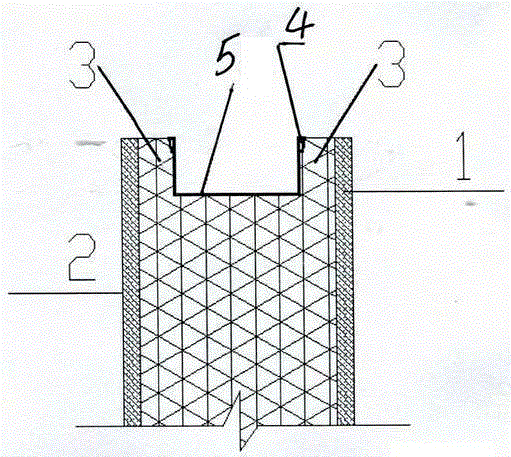

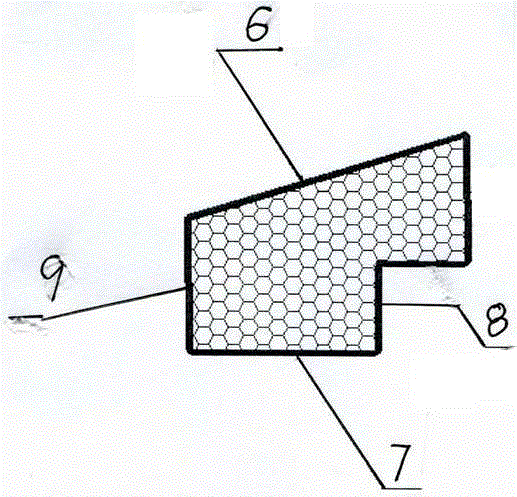

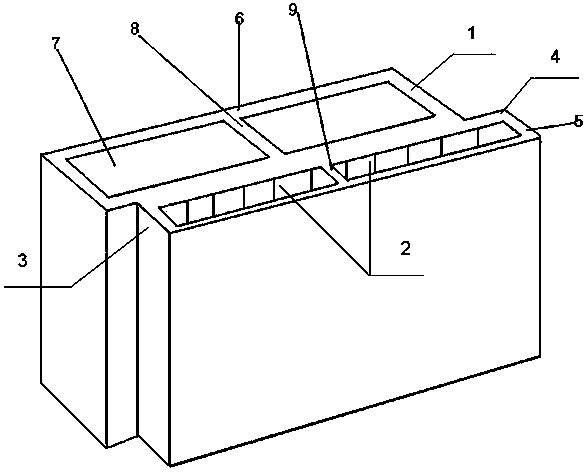

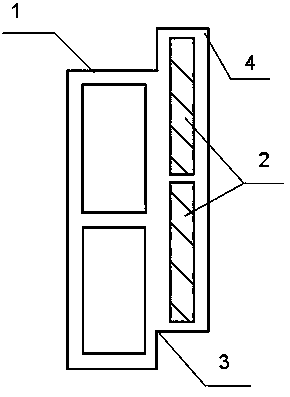

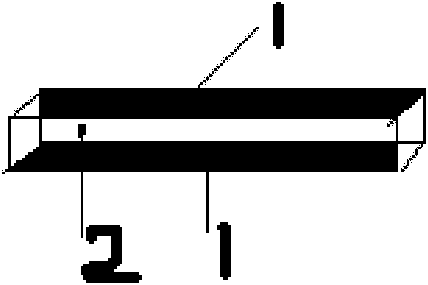

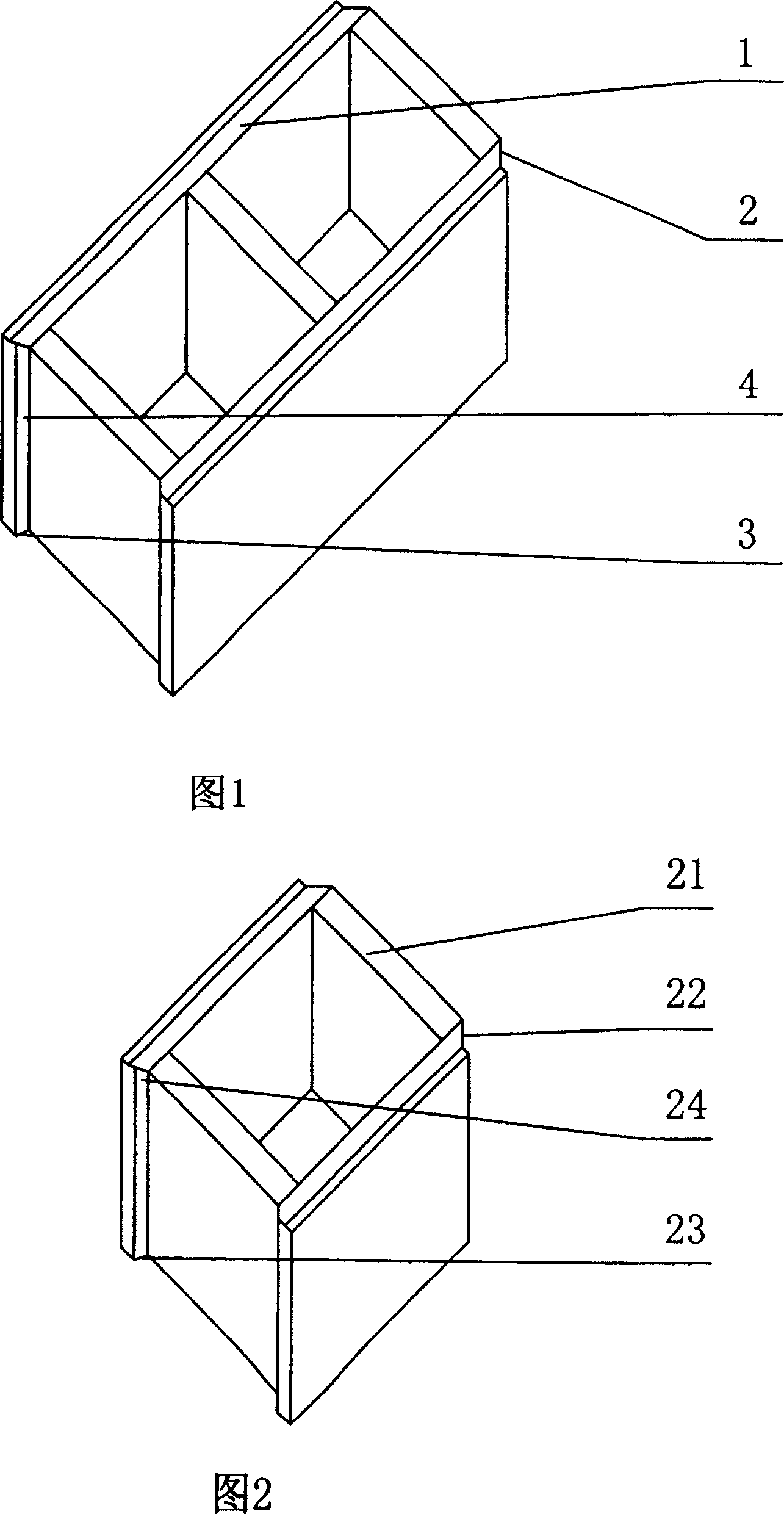

The invention discloses a solar water heater, which comprises a water tank for storing heated hot water, wherein the water tank is of a cubic structure, and a heat-preservation layer is arranged on the outside of the cubic structure; the heat-preservation layer is a heat-preservation building block; the heat-preservation building block is formed by seamlessly and closely combining a concrete substrate (1) and a vacuum insulation panel (2); the vacuum insulation panel (2) divides the concrete substrate (1) into two parts, and the two parts are closely adhered to form a sandwich structure; a mortise (3) and a glossal groove (4) are arranged on the left and right sides of the heat-preservation building block. The solar water heater is provided with the heat-preservation building block, so that the loss of heat is effectively prevented, and energy resources are saved.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

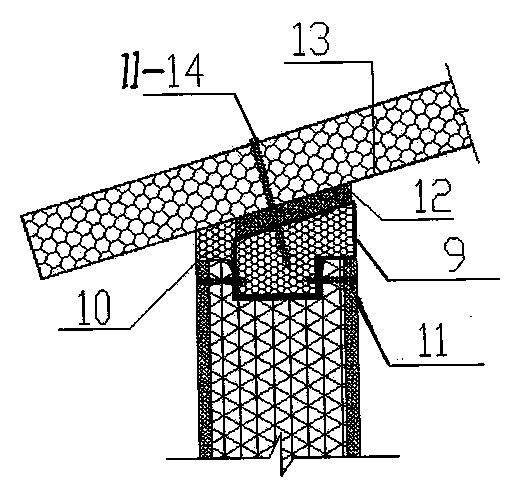

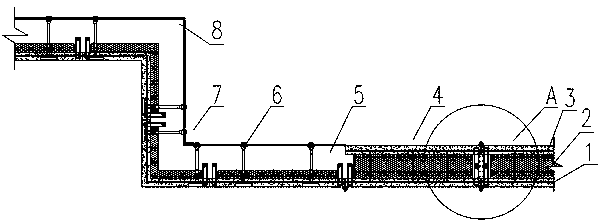

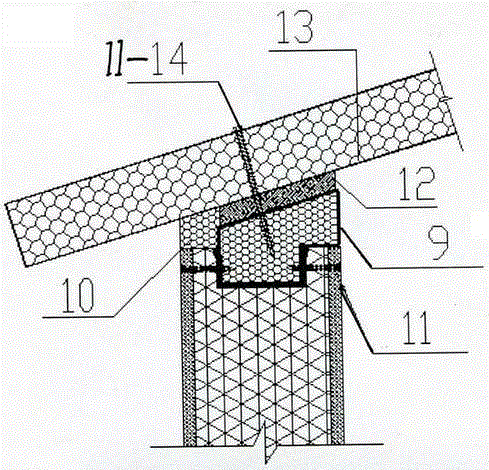

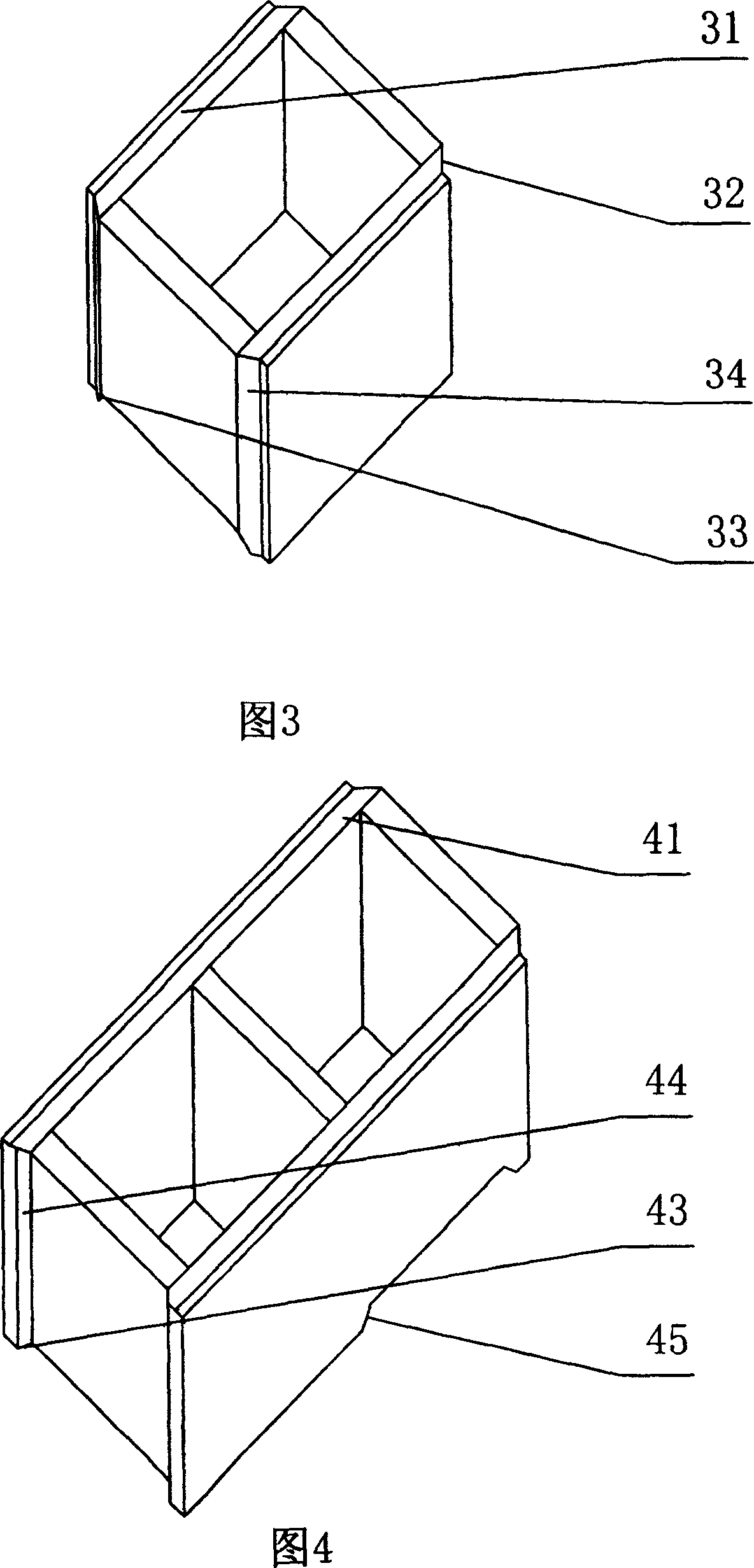

Pitched roof and wallboard connected cold and hot broken bridge structure

The invention discloses a pitched roof and wallboard connected cold and hot broken bridge structure. A groove in the upper end of a wallboard contains an insert, the insert of the groove is filled with a special-shape sectional material, a heat preservation sealing layer is arranged at the lap joint position of the special-shape sectional material and a roof panel, the heat preservation sealing layer is pasted on the slope at the upper end of the special-shape sectional material and forms the broken bridge with a pitched roof plate, and the pitched roof plate is fastened with the special-shape sectional material through a fastening part and a heat preservation layer. The structure is convenient to install, has the heat preservation, energy saving, good sealing and sound insulation, and can improve structural overall strength, rigidity and stability of an integrated residence house.

Owner:河南德霖集成房屋有限公司

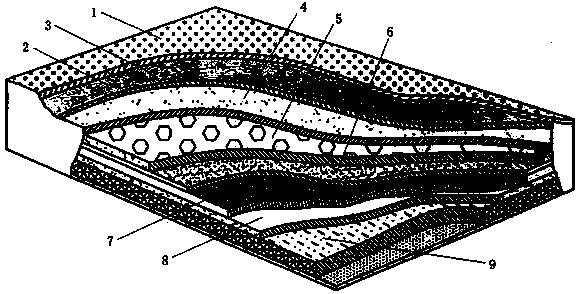

Bionic sleep multifunctional multi-layer structure mattress

InactiveCN108324007AImprove microcirculationImprove immunityElectrotherapyStuffed mattressesMedicineFar infrared

The invention discloses a bionic sleep multifunctional multi-layer structure mattress, which comprises a mattress main body and a mattress outer coating layer, wherein a bamboo fiber antibacterial carbon crystal cloth weaving layer, a magnet layer, a silver fiber anti-radiation layer, a latex pressure-retarding layer, a far infrared heat generation element layer, a negative ion cotton layer, a Chinese herb fiber layer and an elastic multi-layer coconut fiber layer are sequentially superposed from top to bottom to form the mattress main body, the mattress main body is coated with the mattress outer coating layer, the mattress outer coating layer and the bamboo fiber antibacterial carbon crystal cloth weaving layer are fixed through sewing, and the layers are adhered through natural latex. The bionic sleep multifunctional multi-layer structure mattress of the present invention has characteristics of water resistance, oil resistance, antibacterial property, negative ion release, good elasticity, toughness, durability, safety, comfort, health and environmental protection.

Owner:黄 建华

Method for manufacturing hollow brick by using non-recyclable waste

ActiveCN104446179AImprove performance indicatorsSave resourcesSolid waste managementBrickHazardous substance

The invention provides a method for manufacturing a hollow brick by using non-recyclable waste. The method comprises the following steps: firstly, crushing the non-recyclable waste and then passing through a belt with a magnet to recover metals; separating and drying organic matters and inorganic matters in the crushed non-recyclable waste in a flotation device; finally crushing the obtained inorganic matters and organic matters, mixing the inorganic matters, the organic matters and cement, adding water and stirring into slurry; putting into a mold, and carrying out vibration molding or pressure molding; and carrying out natural curing to form a hollow brick product. Compared with a traditional hollow brick, the hollow brick produced by the method has the advantages that all performance indices are improved at different extents; meanwhile, the hollow brick is simple in preparation process and high in practicability; a traditional treatment method for stacking and filling the non-recyclable waste is changed; consumption of soil resources and emission of toxic and harmful substances are reduced; and cyclic utilization of resources is achieved on the bases of environment protection and energy conservation.

Owner:青岛福创环境科技有限公司

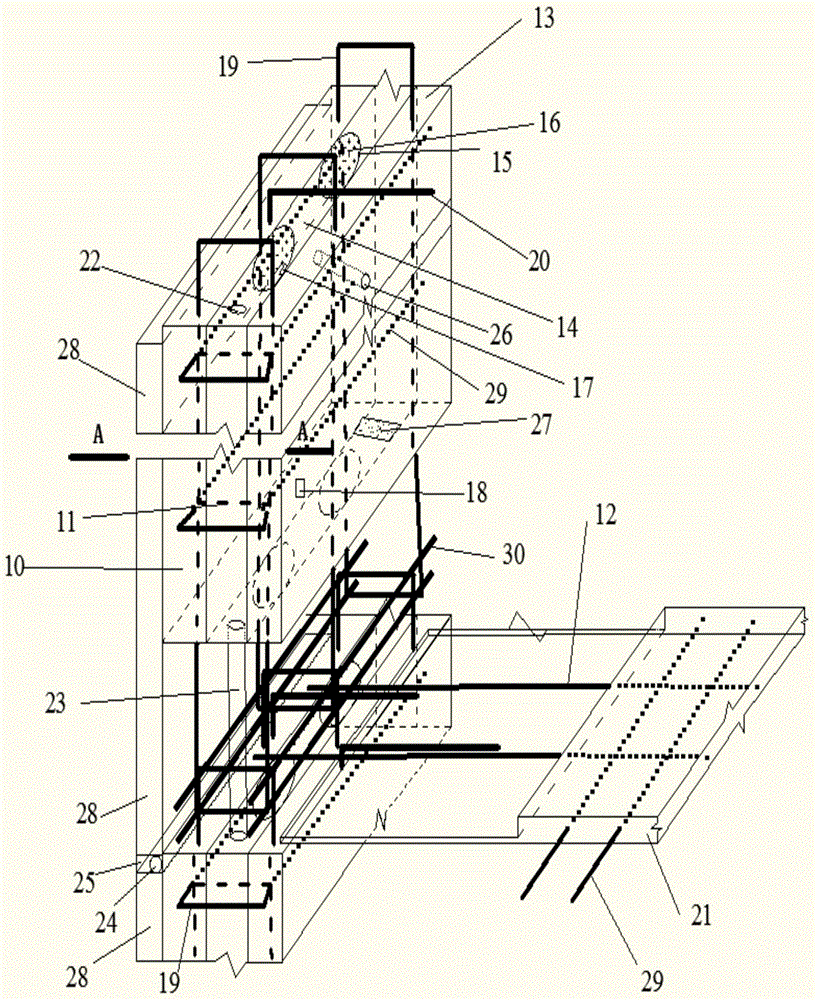

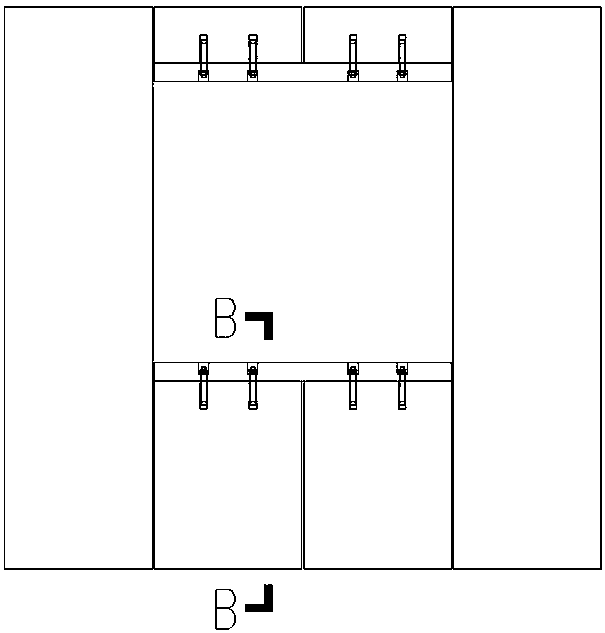

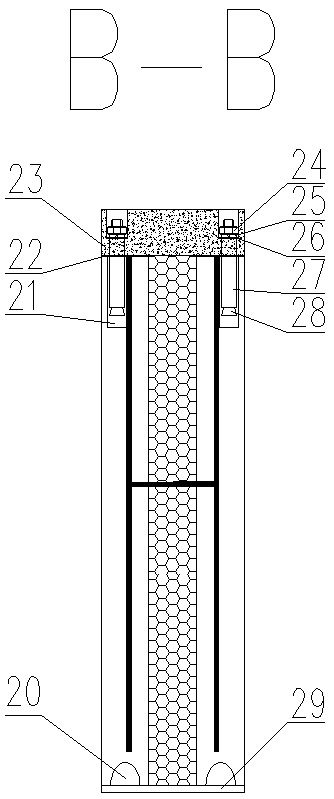

A horizontal self-locking assembled wall panel and its construction method embedded in a building wall

ActiveCN104763098BImprove integrityImprove seismic performanceWallsClimate change adaptationKeelFireproofing

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES +1

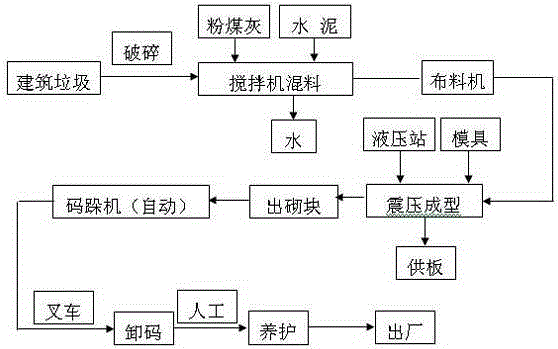

Method for producing wall material with construction waste

InactiveCN105198305AHigh compressive and tensile indexConvenience for masonrySolid waste managementPulverised fuel ashConstruction aggregate

The invention relates to a method for producing a wall material with construction waste. The method includes the steps that the construction waste is smashed to meet the particle requirement for standby application; the construction waste serving as main aggregate, flyash serving as secondary aggregate and a binding material as well as cement and water which serve as gelatinizing materials for improving strength are stirred and mixed evenly by a certain ratio; the mixed materials mixed evenly are fed into a mold and a hydraulic pressure station to be formed in a vibrated and pressed mode; cut blocks are formed through a feeding plate, fed to a stacker crane to be stacked and then unstacked; after unstacking, the finished product is obtained through manual curing. The construction waste concrete is fully used, the produced wall material is high in strength, resources and cost are saved, and the method has great social benefits and economic benefits.

Owner:陕西九长建设总公司

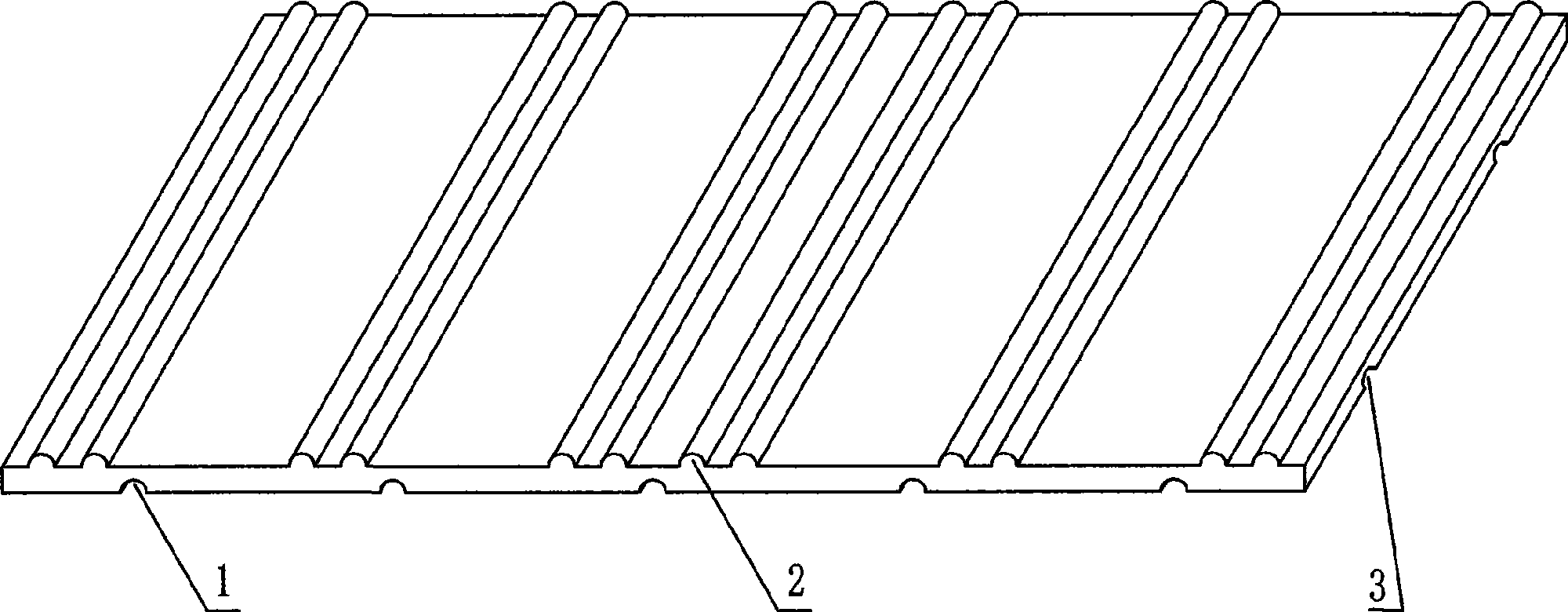

Solar water heater

ActiveCN104214979ASave energyReduce consumptionSolar heating energyConstruction materialCompound aInsulation layer

The invention discloses a solar water heater, which comprises a water tank, wherein the water tank is used for storing heated hot water and is of a cube structure, a heat insulation layer is arranged outside the cube structure, the heat insulation layer is a heat insulation building block and is formed by compounding a concrete substrate (1) and a vacuum heat insulation plate (2), the vacuum heat insulation plate (2) is positioned in an open groove of the concrete substrate (1), and mortices (3) and glossal grooves (4) are formed at the upper and lower sides and the left side and the right side of the heat insulation building block. The solar water heater has the advantages that the heat insulation building bock is adopted, the heat loss is effectively prevented, and the energy sources are saved.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Environment-friendly module component for steel structure building beam column decoration and production method thereof

InactiveCN111892354ASolid density is highHigh compressive strengthCeramicwareFoaming agentArchitectural engineering

The invention relates to an environment-friendly module component for steel structure building beam column decoration and a production method thereof. The environment-friendly module component is prepared from the following raw materials by mass: 240-300 parts of a cementing material, 240-300 parts of fine aggregate, 0.5-1.5 parts of a foaming agent, 0.5-1.5 parts of a foam stabilizer, 0.5-1.5 parts of a reinforcing material and 240-330 parts of water, wherein the ratio of water to materials is 0.50-0.55; the environment-friendly module component product is non-toxic and harmless, the water absorption rate is low, and the service life is longer than 50 years; while industrial wastes are fully utilized, the consumption of raw materials and energy sources is reduced, the working environmentof industrial workers is improved, and the production and construction efficiency is improved.

Owner:ANGANG CONSTR CONSORTIUM

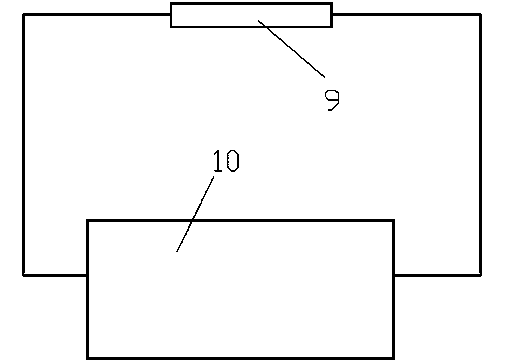

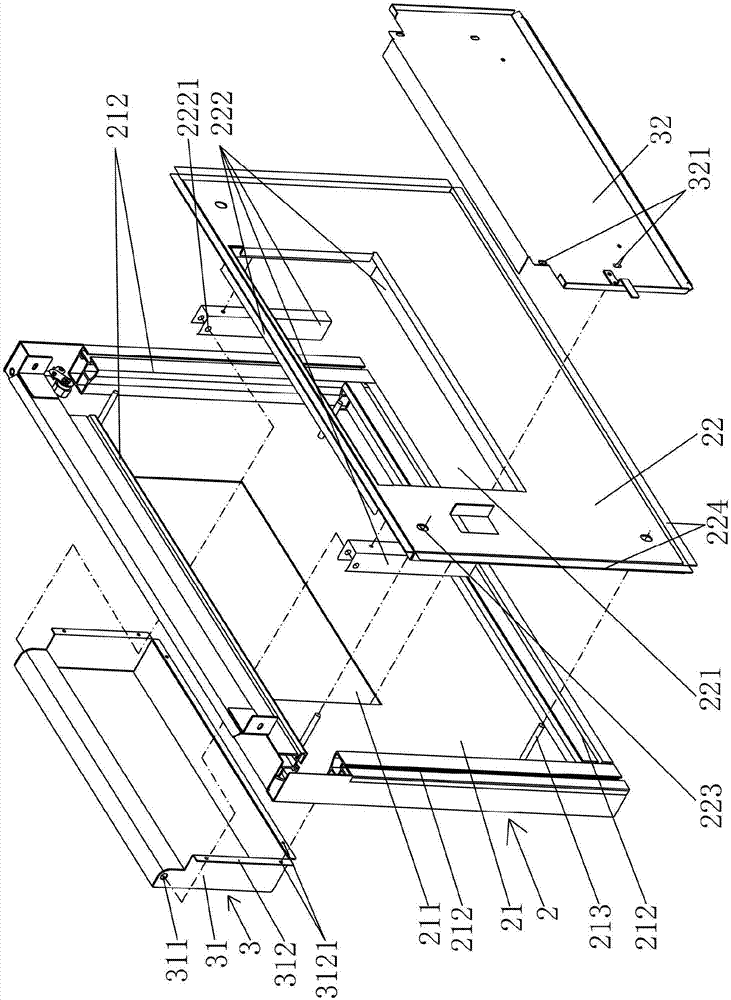

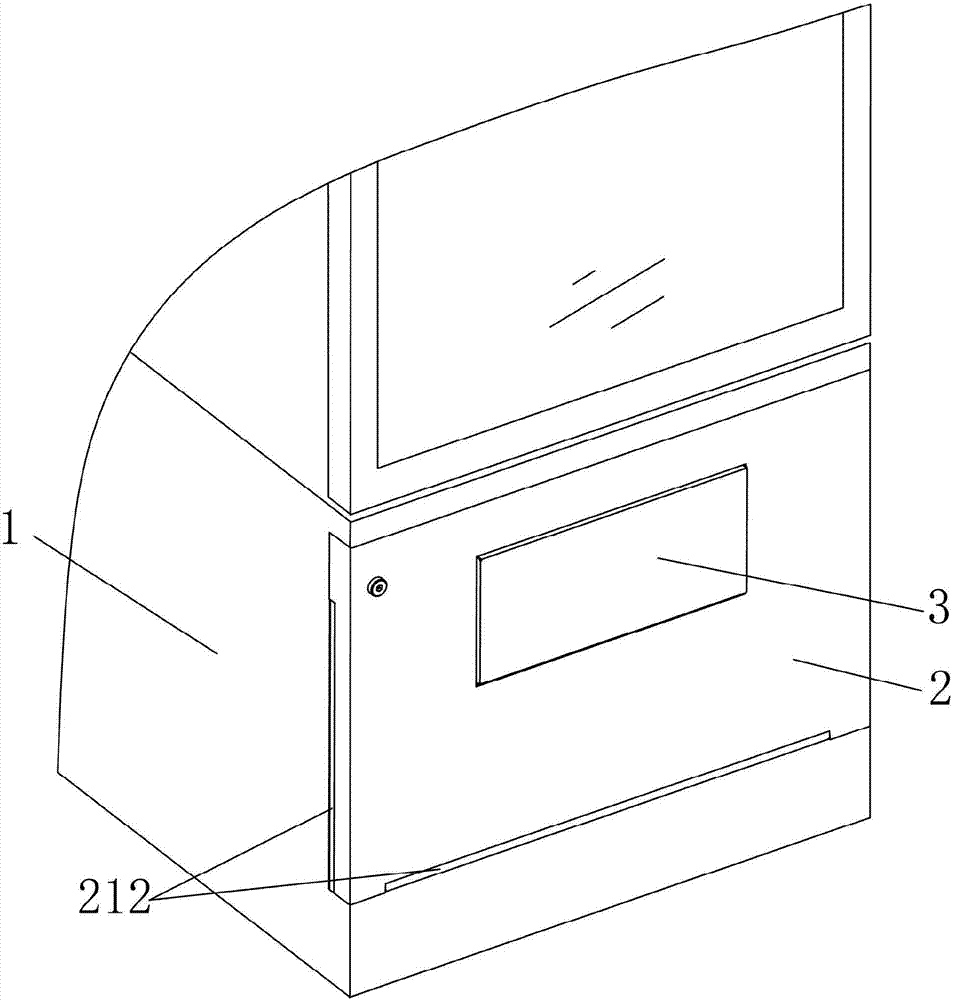

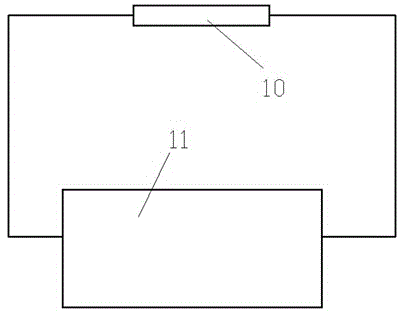

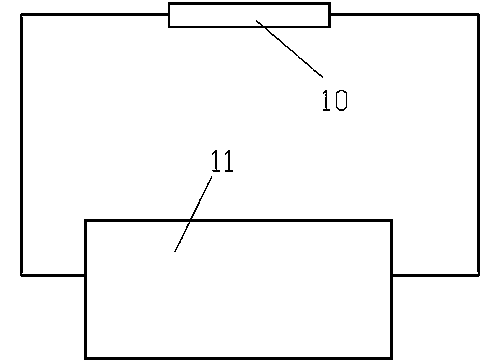

Vending machine with object taking opening with bridge-cutoff structure

InactiveCN107221078AWith thermal insulation and energy savingImprove sealingCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringLocking plate

The invention discloses a vending machine with an object taking opening with a bridge-cutoff structure. The vending machine comprises a vending machine body, a locking plate is mounted below the front side of the vending machine body, and an object taking door is arranged on the locking plate. The vending machine is characterized in that the locking plate includes an outer locking plate and an inner locking plate, the inner locking plate is mounted in the middle of one side of the outer locking plate, an inner locking plate object taking opening is formed in the inner locking plate, an outer locking plate object taking opening is formed in the outer locking plate, an outer cold insulation strip is arranged on the periphery of the outer side of the outer locking plate, faces one side surface of the inner locking plate and is blocked between connecting gaps of the outer locking plate and the vending machine body, condensation at the edge of the gaps is prevented, the inner locking plate is positioned in the outer cold insulation strip, an inner cold insulation strip is fixed on one side surface of the inner locking plate facing the outer locking plate around the inner locking plate object taking opening, the object taking door is mounted on the inner cold insulation strip of two sides of the inner locking plate object taking opening, and the inner cold insulation strip is blocked at the object taking openings of the outer locking plate and the inner locking plate, so that condensation on the periphery of the outer locking plate object taking opening is prevented. The vending machine has the advantages that temperature is kept, energy is saved, sealing is good and condensation prevention effect is better.

Owner:苏州富士宝电器有限公司

Solar system

ActiveCN104879929ASave energyReduce consumptionSolar heating energyConstruction materialCompound aInsulation layer

The invention discloses a solar water heater, which comprises a water tank, wherein the water tank is used for storing heated hot water and is of a cube structure, a heat insulation layer is arranged outside the cube structure, the heat insulation layer is a heat insulation building block and is formed by compounding a concrete substrate (1) and a vacuum heat insulation plate (2), the vacuum heat insulation plate (2) is positioned in an open groove of the concrete substrate (1), and mortices (3) and glossal grooves (4) are formed at the upper and lower sides and the left side and the right side of the heat insulation building block. The solar water heater has the advantages that the heat insulation building bock is adopted, the heat loss is effectively prevented, and the energy sources are saved.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

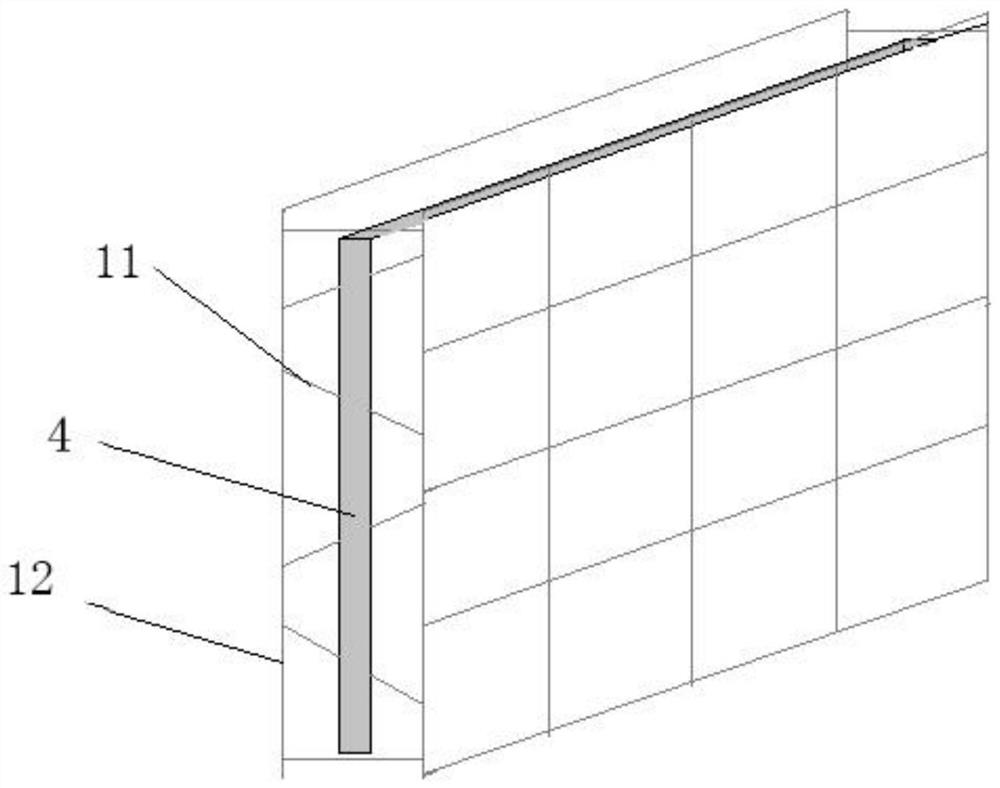

A prefabricated exterior wall structure

ActiveCN107700697BSimple structureEconomically reasonableWallsHeat proofingAccessory structureLoad-bearing wall

The invention discloses a prefabricated fabricated type structure of an external wall, and relates to the field of constructional engineering. The prefabricated fabricated type structure of the external wall is composed of a thermal insulating composite wall standard piece and an auxiliary structure; the thermal insulating composite wall standard piece comprises a prefabricated type external wallload-bearing wall standard piece, a prefabricated type external wall non-bearing wall standard piece and a prefabricated type external wall load-bearing wall internal and external corner standard piece; and the prefabricated type external wall load-bearing wall standard piece is provided with an assembly type oppositely-pulling rod which is used for positioning and installing of a load-bearing wall construction formwork. According to the prefabricated fabricated type structure of the external wall, the structure is simple, economical and reasonable, the technology is advanced, using is convenient, and the prefabricated fabricated type structure is the best construction method of a composite wall structure and has good popularizing value.

Owner:河南纽沃建筑科技有限公司

Light and environment-friendly board and preparation method thereof

The invention discloses a light and environment-friendly board. The board is prepared from raw materials in parts by weight as follows: 10-30 parts of waste circuit board aggregates, 15-25 parts of plastic, 10-20 parts of reed stalk, 7-13 parts of perlite, 13-18 parts of starch, 5-10 parts of ceramsite, 4-7 parts of glass beads, 15-25 parts of fly ash, 8-17 parts of active nano calcium carbonate, 2-5 parts of methyl cellulose, 3-4 parts of lignin, 2-3 parts of a flame retardant, 3-8 parts of a Chinese herbal medicine mixture and 1-2 parts of a bactericide. The light and environment-friendly board is light in mass, excellent in performance, energy-saving, environment-friendly, capable of realizing sufficient waste utilization, low in production cost and suitable for popularization.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Method for preparing high-performance composite wallboard by using waste construction waste or industrial waste residue

PendingCN114182874AReduce manufacturing costGood environmental effectConstruction materialCeramicwareInsulation layerProcess engineering

The invention relates to a method for preparing a high-performance composite wallboard by using waste construction wastes or industrial waste residues, the composite wallboard is composed of hard layers with holes, a middle sandwich heat insulation layer and a reinforcing steel reinforcement cage, the upper and lower mesh surfaces of the reinforcing steel reinforcement cage are respectively embedded in the middle of the hard layers with the holes; comprising the following steps: step 1, preparing a base material of a hard layer with holes; step 2, assembling a mold; thirdly, a plastic core-pulling pipe is inserted, and the plastic core-pulling pipe is inserted into the mold along the hole of the plug on one side of the mold and comes out of the other end of the plug with the hollow part; and 4, pouring a hard layer base material with holes, and solidifying and demolding to form the product. According to the invention, the existing construction waste or industrial waste residue is used as the raw material to manufacture and produce the composite wallboard, so that a large amount of waste construction waste or industrial waste residue can be reasonably utilized, waste is turned into wealth, the production cost of the composite wallboard can be greatly reduced, and a good environment-friendly effect is achieved.

Owner:杨博

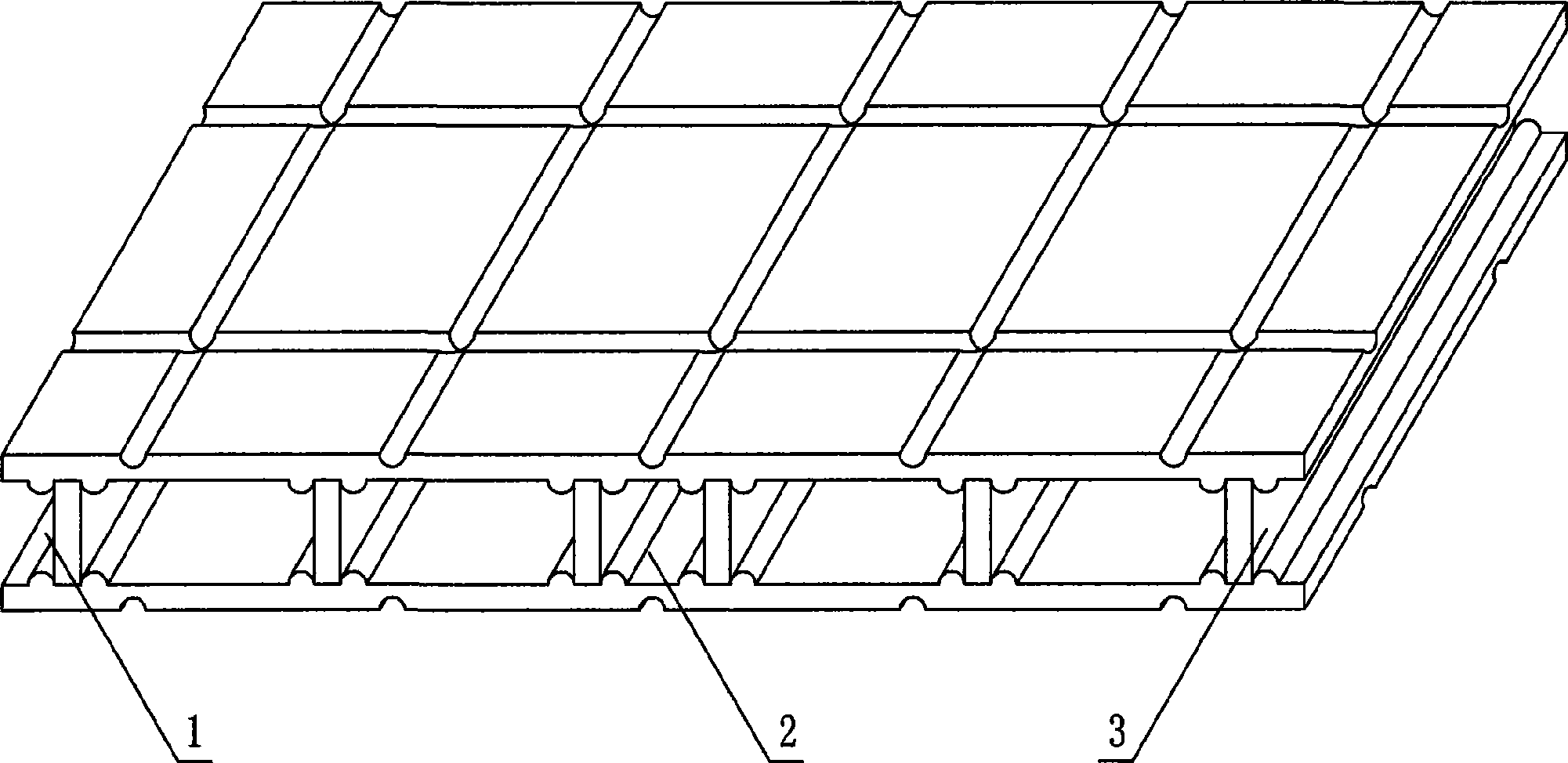

Decorative combination gypsum wall big slab and installation construction method

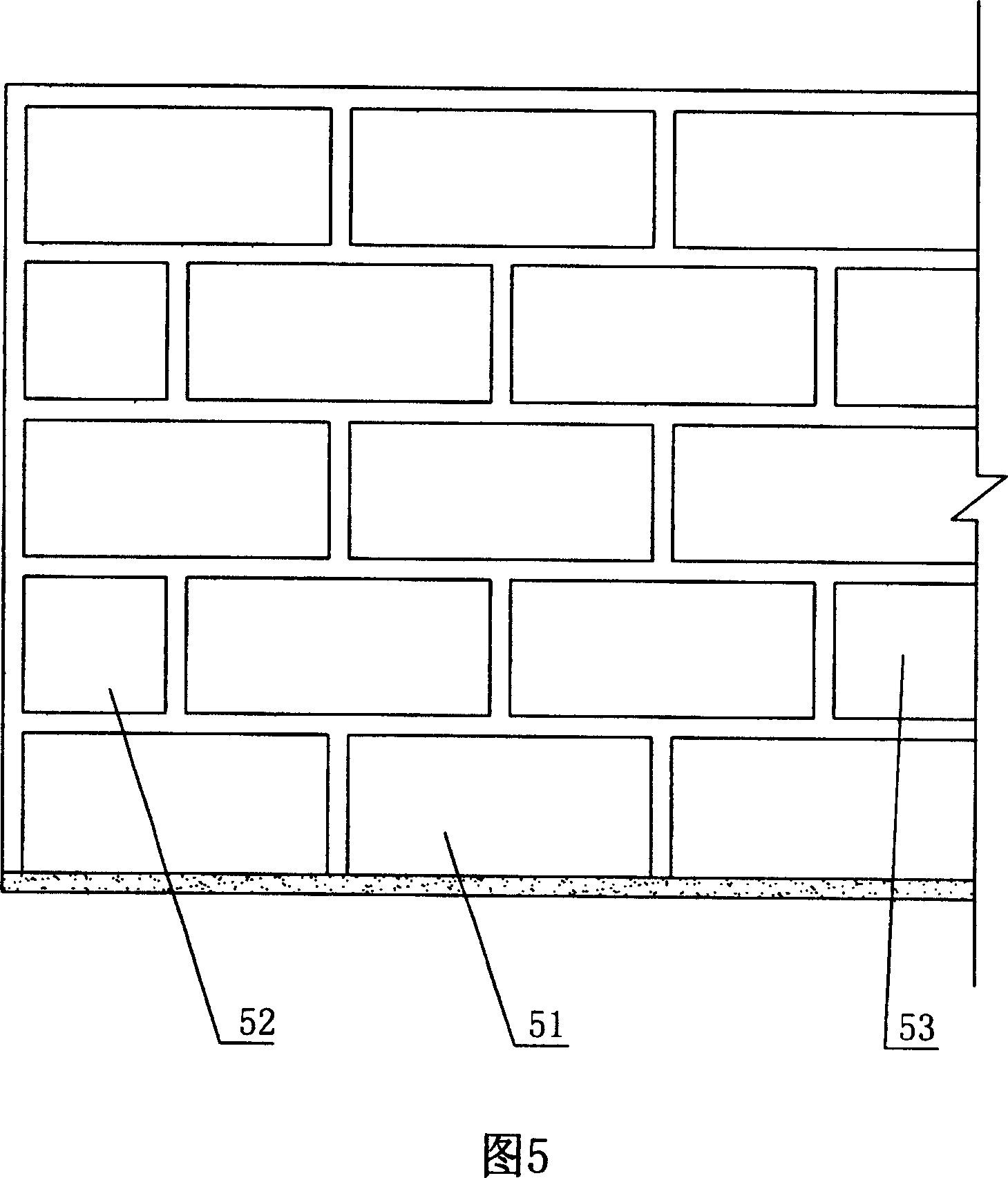

The invention introduces a decorative combined gypsum wall body big plate and a mounting and construction method thereof. The main material of concrete or gypsum and auxiliary materials are compounded together to form the combined big plate. The combined big plate is structurally formed by assembling and combining wall panels and movable ribs. During the installation, the wall panels and the movable ribs are fixed together through gun nails at the external surfaces of the wall panels corresponding to the movable ribs. After fixation, a plurality of rectangular holes 2 and groove-shaped holes 1, 3 are formed between the wall panels, and gypsum slurry or concrete slurry is injected into the rectangular holes or the groove-shaped holes through mechanical compression. Therefore, the wall panels and the precast beams of a building are adhered into a whole so as to bring about a firm and reliable wall body.

Owner:罗国军

A method of making hollow bricks from non-recyclable waste

ActiveCN104446179BImprove performance indicatorsSave resourcesSolid waste managementBrickHazardous substance

The invention provides a method for manufacturing a hollow brick by using non-recyclable waste. The method comprises the following steps: firstly, crushing the non-recyclable waste and then passing through a belt with a magnet to recover metals; separating and drying organic matters and inorganic matters in the crushed non-recyclable waste in a flotation device; finally crushing the obtained inorganic matters and organic matters, mixing the inorganic matters, the organic matters and cement, adding water and stirring into slurry; putting into a mold, and carrying out vibration molding or pressure molding; and carrying out natural curing to form a hollow brick product. Compared with a traditional hollow brick, the hollow brick produced by the method has the advantages that all performance indices are improved at different extents; meanwhile, the hollow brick is simple in preparation process and high in practicability; a traditional treatment method for stacking and filling the non-recyclable waste is changed; consumption of soil resources and emission of toxic and harmful substances are reduced; and cyclic utilization of resources is achieved on the bases of environment protection and energy conservation.

Owner:青岛福创环境科技有限公司

A method for producing energy-saving panels

The invention belongs to the fields of sheet material processing, and energy saving and environment protection, and specifically relates to a production method of an energy saving sheet material. The production method comprises the following steps: step one, preparing slurry; step two, preparing a base material; step three, moulding; and step four, carrying out maintenance and demoulding. According to the production method, fly ash, waste cement bricks, and waste ceramic are taken as the raw materials, the cost is low, the wastes are utilized, the environment is protected; the produced sheet material has the advantages of thermal insulation performance, energy saving property, high anti-seismic performance, fireproof property, soundproof property, dampness resistance, long lasting effect, capability for nailing, hanging and hoisting, light weight, and convenience for construction, can be sawed, polished, drilled, and nailed, is capable of being spliced at will, can be transported at any time if not being fixed, and can be adhered with cement slurry. The manufacturing technology is the same as that of floor tiles. No special treatment or water soaking is needed, so that a large amount of labor and money is saved. At the same time, the energy saving sheet material obtained by the provided production method has a good thermal insulation effect.

Owner:广西塔锡科技有限公司

Processing method of novel light energy-saving environmental-protection board

ActiveCN101733821BWith thermal insulation and energy savingFireproofSolid waste managementMixing operation control apparatusLight energyPolyvinyl alcohol

The invention discloses a processing method of a novel light energy-saving environmental-protection board, belonging to the field of processing professional technology of building wall body material; the basic technical proposal is that: the novel light energy-saving environmental-protection board is manufactured by the waste polystyrene foam, industrial production waste coal cinder or coal ash, building-removal waste residue, industrial production waste desulfuration gypsum, low-alkali sulphate aluminium cement, special chemical additive and water by weight parts, wherein the special chemical additive is prepared by radiating polyvinyl alcohol, polyacrylic acid, methylcellulose, lignin and boric acid which have a certain weight parts by Co-gamma rays; compared with the traditional wall body material, the novel composite molding board has the advantages of low cost, temperature insulation, energy saving, high-intensity shock resistance, sound insulation, moisture proofing, durability,light weight, simple manufacturing process, convenient construction, and being capable of fastening hangers, is completely accordance to the national green development requirements of energy saving, environment protection and waste utilization, therefore, the processing method of the novel light energy-saving environmental-protection board is an ideal sustainable development green wall body material.

Owner:WUHAN WEIJUN IMPORT & EXPORT TRADE CO LTD

A cold and hot broken bridge structure with sloping roof and wall panels

The invention discloses a pitched roof and wallboard connected cold and hot broken bridge structure. A groove in the upper end of a wallboard contains an insert, the insert of the groove is filled with a special-shape sectional material, a heat preservation sealing layer is arranged at the lap joint position of the special-shape sectional material and a roof panel, the heat preservation sealing layer is pasted on the slope at the upper end of the special-shape sectional material and forms the broken bridge with a pitched roof plate, and the pitched roof plate is fastened with the special-shape sectional material through a fastening part and a heat preservation layer. The structure is convenient to install, has the heat preservation, energy saving, good sealing and sound insulation, and can improve structural overall strength, rigidity and stability of an integrated residence house.

Owner:河南德霖集成房屋有限公司

Nanometer silver carbon based inner wall coating

The invention provides a nano-silver carbon silicon interior wall paint. Calcium powder and diatomite powder crushed into 300 meshes to 400 meshes of fine powder, perlite powder and active carbon powder crushed into 50 meshes to 70 meshes of fine powder are mixed and added with nano-silver and water to be blended into slurry state to form the paint. The paint of the invention utilizes the nano-silver broad-spectrum high-efficiency sterilization (virus killing) mechanism, and the coconut shell carbon and diatomite adsorption filtration energy-conservation principle to act on the surface of thewall, and is characterized by sterilization, mold resistance, adsorption, air purification, negative ion releasing, fireproofness, fire retardation, heat preservation, energy conservation, etc., and remedies and solves all the disadvantages of traditional wall materials. The paint of the invention can be used for the decoration and fitment of all interior walls as the wall materials.

Owner:吉林省嘉鹏硅藻土研发有限责任公司

Glass magnesium decorative board manufacturing process

ActiveCN102991086BWith thermal insulation and energy savingHigh strengthLamination ancillary operationsLaminationPublic placeAdhesive glue

The invention relates to a manufacturing process for a glass-magnesium decorative plate. The glass-magnesium decorative plate is composed of a substrate plate and melamine impregnated paper, wherein the substrate plate is a glass-magnesium flat plate; and the melamine impregnated paper is decorative paper impregnated by melamine glue. The manufacturing process disclosed by the invention comprises the following steps of: impregnating the high-brightness decorative paper, pre-processing the glass-magnesium flat plate, pressing and sticking the glass-magnesium flat plate at a high temperature, so as to obtain the glass-magnesium decorative plate. The manufacturing process disclosed by the invention is easy to operate. The surface of the manufactured decorative plate is attractive in color. The glass-magnesium decorative plate has the special performances of being environment-friendly, energy-saving, light in weight, fireproof and the like and is widely applied in public places, such as suspended ceilings, indoor partition walls and door plates, as well as applied in high-grade places, such as office buildings and entertainment places.

Owner:ZHEJIANG DILONG NEW MATERIAL

A lightweight castable for sintering ignition furnace

ActiveCN107573098BLow thermal conductivityImprove insulation effectCeramicwareThermal insulationSodium phosphates

Owner:武汉钢铁有限公司

Solar water heater

ActiveCN104180546AEnergy savingSave space and materialSolar heating energyConstruction materialSolar waterVacuum insulated panel

The invention discloses a solar water heater, which comprises a water tank for storing heated hot water, wherein the water tank is of a cubic structure, and a heat-preservation layer is arranged on the outside of the cubic structure; the heat-preservation layer is a heat-preservation building block; the heat-preservation building block is formed by combining a concrete substrate (1) and a vacuum insulation panel (2); the vacuum insulation panel (2) is positioned in an open groove of the concrete substrate (1); a mortise (3) and a glossal groove (4) are arranged on the left and right sides of the heat-preservation building block. The solar water heater is provided with the heat-preservation building block, so that the loss of heat is effectively prevented, and energy resources are saved.

Owner:ANHUI KERUIKE INSULATION MATERIAL

Flame retardant polyurethane material as well as preparation method and application thereof

The invention belongs to the technical field of high molecular material modification and discloses an energy-saving environment friendly sound insulation flame retardant polyurethane material as well as a preparation method and application thereof. The flame retardant polyurethane material consists of the following components in parts by weight: 100 parts of polyether, 120-145 parts of polyurethane reactive monomer, 4.5-12 parts of foaming agent, 1.5-2.5 parts of foam stabilizer, 20-40 parts of polyester, 0.5-10 parts of compatilizer, 0-2.5 parts of amine catalyst, 0-2 parts of tin catalyst, 10-20 parts of fire retardant, 0-3 parts of flame retardant synergist and 10-20 parts of heat insulation and sound insulation assistant. Compared with the prior art, the energy-saving environment friendly sound insulation flame retardant polyurethane material provided by the invention is light in weight, high in strength, good in waterproof compactness, environment friendly due to no halogen, good in heat preservation, heat insulation and sound insulation effects and good in flame retardance and fireproofness up to the V-0-grade standard of UL-94 when being used as a foam building board. The material can be widely applied to various national economy fields such as the building board and the like.

Owner:GUANGXI LISHENG STONE CO LTD

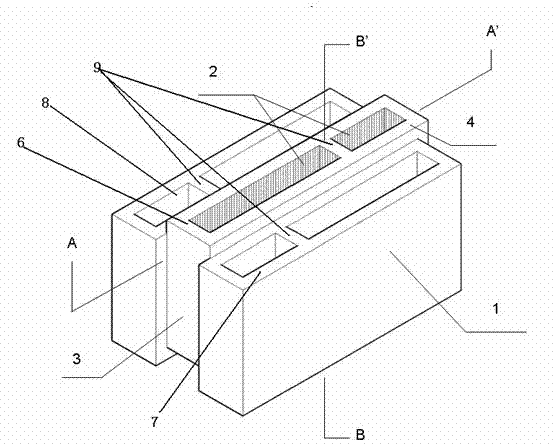

Building blocks and wall building method

InactiveCN1325738CWith sound insulationWith heat insulationWallsArchitectural engineeringBuilding construction

The present invention discloses one kind of building block and its wall building method, and aims at providing one kind of building block with high construction efficiency, low cost, beautiful outer appearance, high waterproof performance and high quality. The building block features that it has boss with bevel and notch with chamfer; and the construction method with the building block is to match the blocks with the bosses and the chamfers. The present invention may be used widely in building engineering.

Owner:李国纯

Nanometer silver carbon based inner wall prime

InactiveCN101323721BSterilization hasAdsorption hasCoatingsActivated carbonActivated charcoal powder

The invention provides a nano-silver carbon-based interior wall basic paint. Active carbon powder crushed into 800 meshes to 1200 meshes of fine powder, calcium powder crushed into 300 meshes to 400 meshes of fine powder and pearlite powder crushed into 50 meshes to 70 meshes of fine powder are mixed and added with nano-silver, an organic adhesive and water to form the paint of the invention. Thepaint of the invention utilizes the nano-silver broad-spectrum high-efficiency sterilization (virus killing) mechanism, and the coconut shell carbon and diatomite adsorption filtration energy-conservation principle to act on the surface of the wall, and is characterized by sterilization, mold resistance, adsorption, air purification, negative ion releasing, fireproofness, fire retardation, heat preservation and energy conservation, etc., and remedies and solves all the disadvantages of traditional wall materials. The paint of the invention can be used for the decoration and fitment of all interior walls as the wall materials.

Owner:NORTHEAST NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com