Glass magnesium decorative board manufacturing process

A manufacturing process and decorative board technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of easy-fading surface effect design, low surface bonding strength, insufficient clarity, etc., to achieve bright color, High surface bonding strength and good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

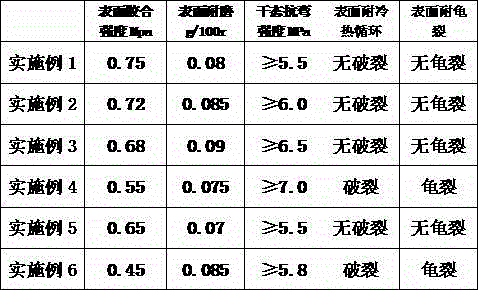

Examples

Embodiment 1

[0035] Example 1 A glass magnesium plate with a thickness of 5 mm is used as the base plate,

[0036] Follow the steps below:

[0037] Step (1): Configure the melamine resin adhesive:

[0038] The base material glue is composed of the following raw materials in the weight ratio: 140kg of formaldehyde solution with a concentration of 36.8% to 37.2% by weight, 110kg of melamine, 65kg of soft water, and 8kg of caprolactam;

[0039] The additives are added after the base glue is made, 0.65kg penetrating agent, 0.32kg antisticking agent, 0.48kg release agent, 0.48kg curing agent and 6.5kg brightening agent.

[0040] The penetrating agent is W7-320 penetrating agent produced by Germany Discovery Star, and its main component is surfactant; the curing agent is 710 curing agent produced by German Woods, and the main component is acidic substances; the release agent is 523 produced by German Woods Release agent, the cured plate is easy to separate from the stainless steel plate after...

Embodiment 2

[0055] Example 2 A glass magnesium plate with a thickness of 9 mm is used as the base material,

[0056] Follow the steps below:

[0057] Step (1): Configure the melamine resin adhesive:

[0058] The raw materials of the base glue are 120kg of 37% formaldehyde solution, 95kg of melamine, 60kg of soft water, and 6kg of caprolactam;

[0059] Auxiliaries are added after the base glue is made, 0.281kg penetrating agent, 0.14kg anti-sticking agent, 0.03kg release agent, 0.14kg curing agent and 0.281kg brightening agent.

[0060] The penetrating agent is alkylbenzene sulfonate; the anti-sticking agent is a solvent-based silicone release agent; the release agent is a purchased melamine resin release agent; the curing agent is a curing agent purchased from Hangzhou Linan Mingsheng Chemical Co., Ltd.; The brightener is phenylacetic acid.

[0061] The preparation method of melamine resin adhesive is to mix formaldehyde and soft water and adjust its pH value to between 9.0 and 9....

Embodiment 3

[0076] Example 3 A glass magnesium plate with a thickness of 12 millimeters is used as a substrate,

[0077] Next follow the steps below:

[0078] Step (1): Configure the melamine resin adhesive:

[0079] The raw materials of the base glue include 140kg of 37.2% formaldehyde solution, 115kg of melamine, 70kg of soft water, and 10kg of caprolactam;

[0080] The additives are added after the base material glue is made, 1kg penetrating agent, 0.67 kg anti-adhesive agent, 1 kg release agent, 0.35 kg curing agent and 3.35 kg brightening agent.

[0081] The penetrating agent is W7-320 penetrating agent produced by Germany Discovery Star, and its main component is surfactant; the curing agent is 710 curing agent produced by German Woods, and the main component is acidic substances; the release agent is 523 produced by German Woods Release agent, the cured plate is easy to separate from the stainless steel plate after pressing.

[0082] Configuration method Mix formaldehyde with so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com