Internal and external corner plastic template

A technology of plastic formwork and internal and external corners, which is applied in the direction of formwork/formwork components, connection parts of formwork/formwork/work frame, and construction components on site. It can solve the problems of plastic formwork without internal and external angles, and achieve convenience Manual operation, reducing workload and ensuring the effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

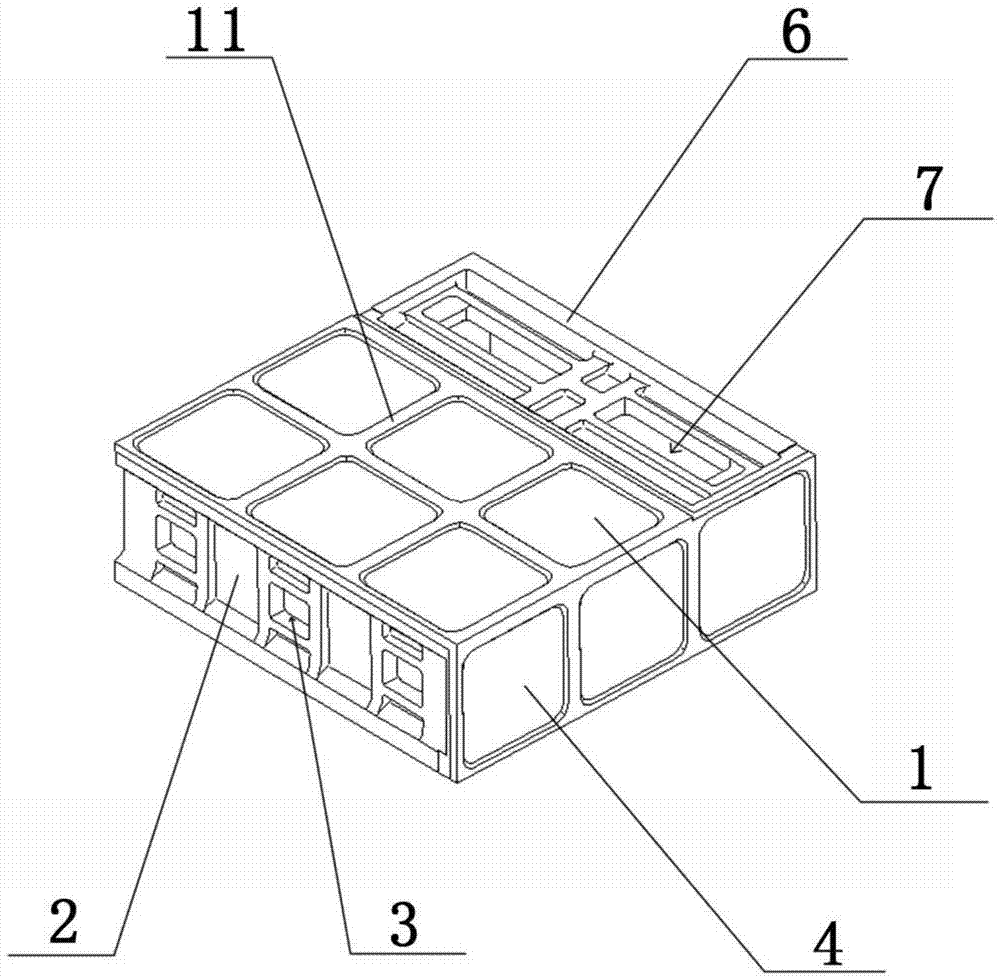

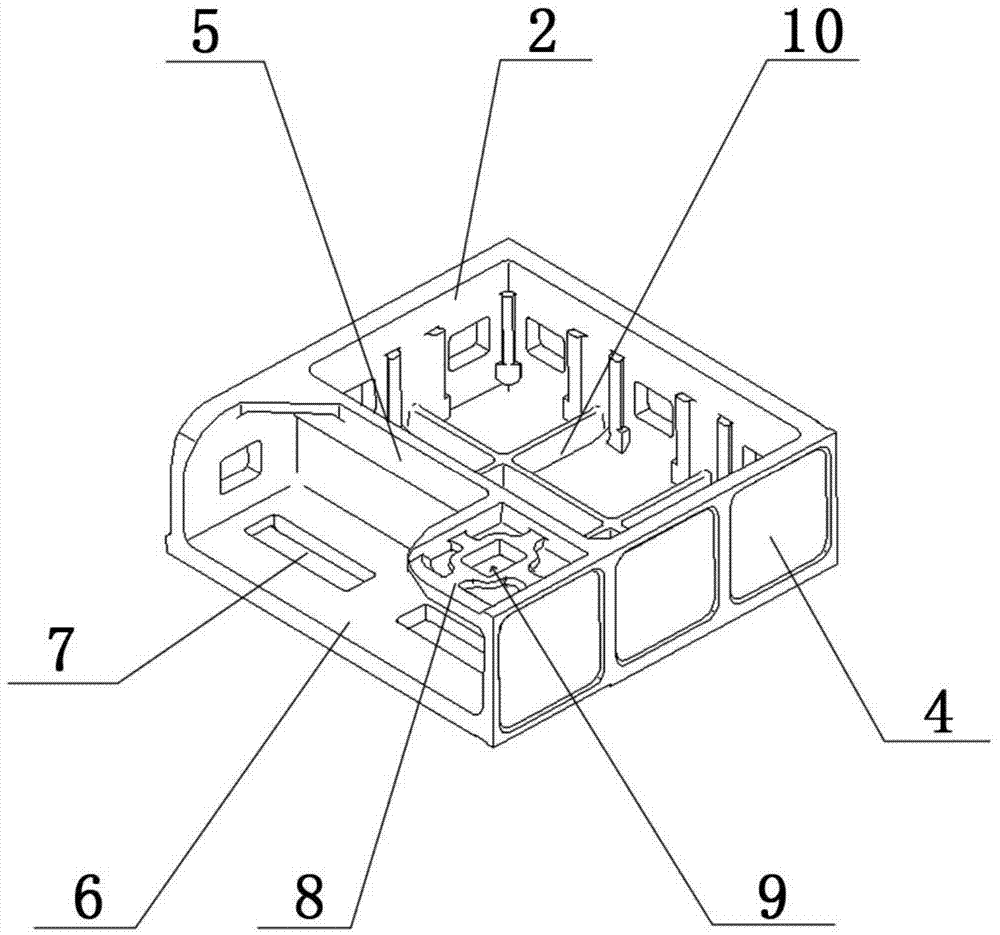

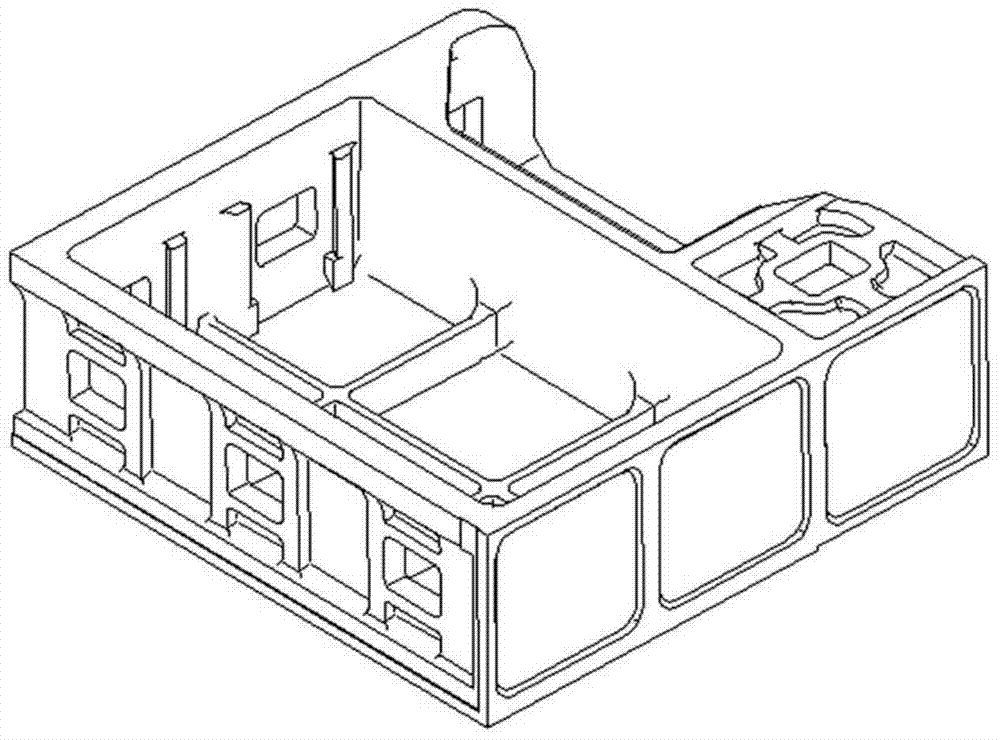

[0019] Such as figure 1 and figure 2 As shown, the panel 1 is a rectangular structure, and a frame 2 perpendicular to the panel 1 is respectively arranged on a long side and a short side of the panel 1. Connecting holes 3 for docking (or connection). On the other short side of the panel 1, a side panel 4 perpendicular to the panel 1 is arranged, and the height of the side panel 4 is the same as that of the frame 2; The side rib 5 of 1, the upper edge of the side rib 5 (that is, the end far away from the panel 1) reaches or approaches the plane where the top surface of the upper edge of the frame 2 (that is, the end far away from the panel 1) is located; the frame 2, the edge sealing side plate 4 and the side ribs 5 are enclosed on the back side of the panel 1.

[0020] An extension plate extending from the panel 1 , connected to the panel 1 and parallel to the panel 1 is provided on the lower edge of the side rib 5 , that is, the extension plate is a male corner connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com