The movable fulcrum metamorphic mechanism of the small arm of the hydraulic drilling rig

A technology of metamorphic mechanism and fulcrum, which is applied in the direction of drilling equipment, earthwork drilling and production, support devices, etc. It can solve the problems of working angle, inconvenient transportation and folding, and the failure of the drilling arm structure to meet the requirements, etc., and achieve the effect of large working angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

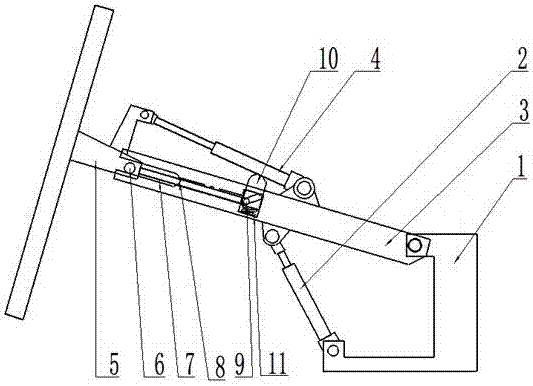

[0007] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0008] Such as figure 1 As shown, the boom 3 is hinged on the body 1, the boom cylinder 2 is hinged on the body 1, the boom cylinder 2 is hinged to the boom 3, the arm hinge point 6 is installed on the arm 5, and the arm hinge point 6 is simultaneously Slide in the boom chute 7, the forearm hinge point connecting rod 8 connects the forearm hinge point 6 and the forearm chute slide block 9, the boom oil cylinder top block 10 is connected with the chute of the forearm chute slide block 9 and It can slide up and down along the chute, and the bottom of the top block 10 of the boom cylinder is connected with the boom 3 through a spring 11 .

[0009] Boom oil cylinder top piece 10 is preloaded on the top by spring 11 during normal work, and forearm hinge point 6 does not slide relative to boom 3, and forearm 5, boom 3, and forearm oil cylinder 4 form a triangular mechanism b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com