Manufacturing method of polaroid, polaroid, display substrate and display device

A technology of polarizer and polarizing layer, which is applied in the direction of optics, polarizing elements, optical elements, etc., can solve the problems of complex process, insufficient antistatic ability, and difficulty in meeting the needs of liquid crystal display devices, so as to ensure display quality and improve anti-static Electrostatic ability and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

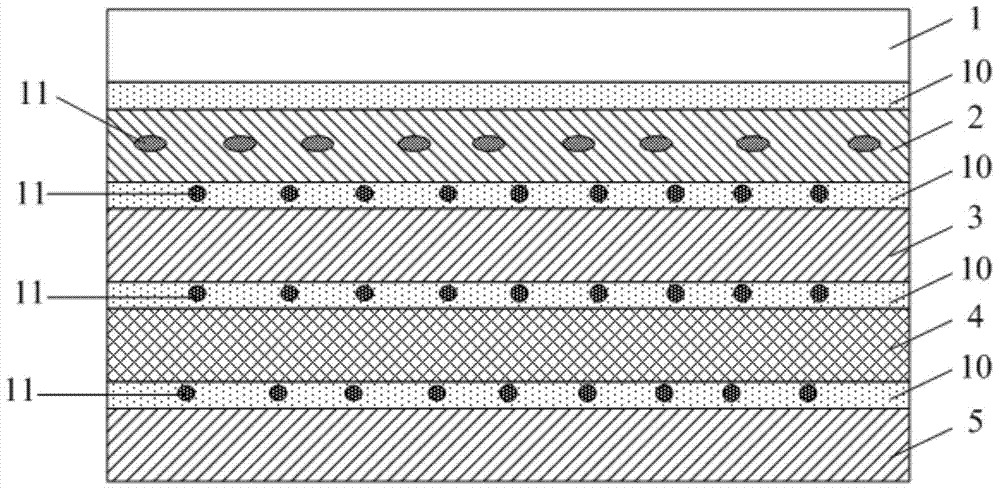

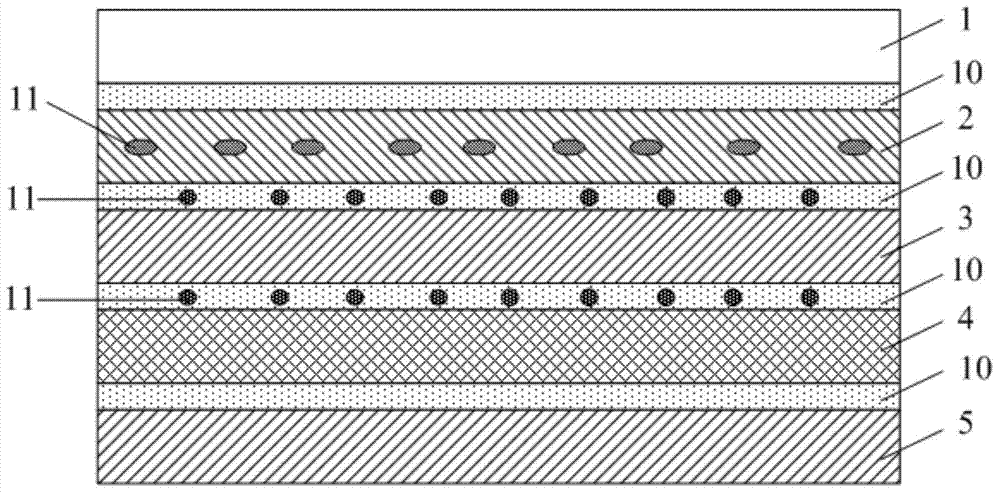

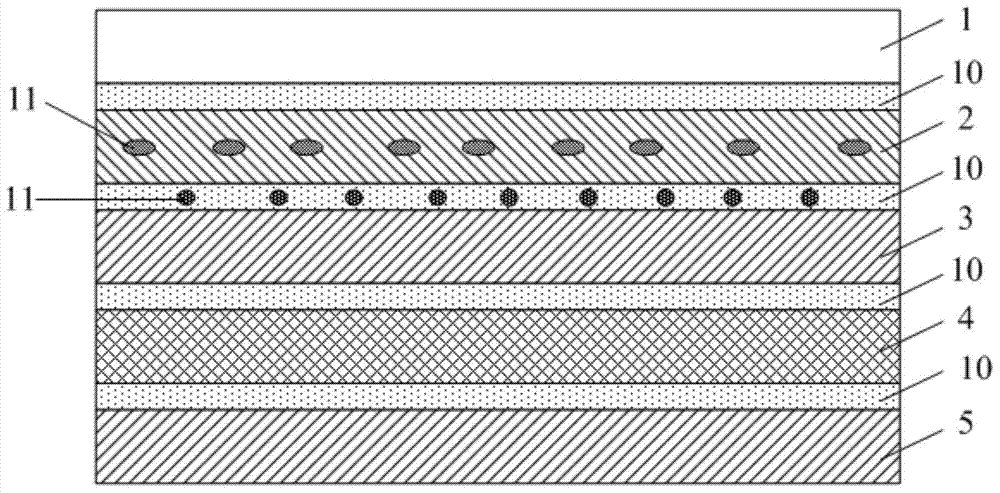

[0027] This embodiment provides a method for preparing a polarizer. The preparation method of the polarizer is to apply an adhesive with a conductive substance on at least one side of the first support layer close to the polarizer, one side or both sides of the polarizer And at least one or both sides of the second supporting layer; or, further adding conductive substances to the surface of the above-mentioned layers while performing surface treatment, so as to improve the antistatic ability of the liquid crystal display using the polarizer.

[0028] Specifically, in the preparation method of the polarizer, it includes the steps of sequentially stacking the protective layer, the first support layer, the polarizer layer, the second support layer and the release film layer through an adhesive. Conductive substances are pre-added in the adhesive between at least one contacting surface of the first supporting layer and the polarizing layer, the polarizing layer and the second suppo...

Embodiment 2

[0048] This embodiment provides a display substrate, including the polarizer in Embodiment 1.

[0049] In this embodiment, the display substrate can be a color filter substrate or an array substrate, liquid crystal is dripped on the array substrate, and the process of combining the color filter substrate and the array substrate (Cell 1) forms a liquid crystal display, the embodiment The polarizer in 1 is attached to the side of the color filter substrate or array substrate relatively away from the liquid crystal.

[0050] The display substrate using the polarizer in Example 1 has better antistatic ability, ensures the display quality of the liquid crystal display screen, and has a high product yield.

Embodiment 3

[0052] This embodiment provides a display device, including the display substrate in Embodiment 2.

[0053] The display device may be any product or component with a display function, such as a liquid crystal panel, electronic paper, a mobile phone, a tablet computer, a television set, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

[0054] The display device using the display substrate in Embodiment 2 has better antistatic ability, ensures the display quality of the liquid crystal display screen, and has a high product yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap