High-exhaust anti-static acrylic protective film and preparation method thereof

An anti-static, acrylic technology, applied in the field of materials, can solve problems such as easy generation of static electricity, small dielectric constant insulation, user hazards, etc., to prevent static electricity accumulation, avoid adverse effects, high exhaust and anti-static properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. Unless otherwise defined, all technical and scientific terms used in this specification have the same meaning as commonly understood by one of ordinary skill in the technical field of the invention.

[0026] refer to figure 1 , figure 1 It is a structural schematic diagram of a high exhaust antistatic acrylic protective film according to an embodiment of the present invention. The high exhaust antistatic acrylic protective film includes a PET film substrate layer 10, an acrylic adhesive layer 20 and a silicon release film layer 30 stacked in sequence. .

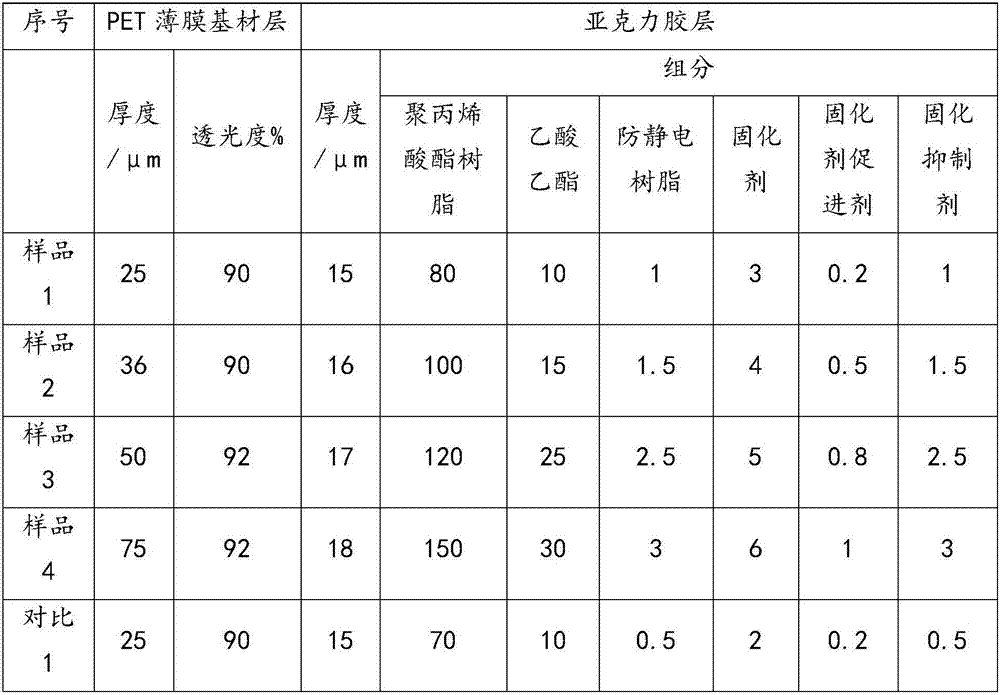

[0027] Preferably, the PET film substrate layer 10 is a highly transparent PET polyester film, and its light transmittance is above 90%. In other embodiments, the PET film substrate layer can also be made of PP, PE or o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap