Three-dimensional CT defect extracting and marking method for solid engine

A technology of solid engine and marking method, which is applied in image data processing, instrumentation, calculation, etc., can solve problems such as single detection method, inability to process in real time, and high price of industrial CT equipment, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

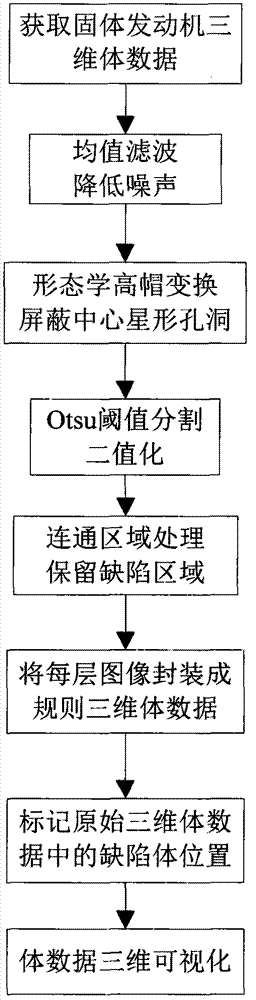

[0029] A solid engine three-dimensional CT defect extraction and marking method disclosed by the invention, such as figure 1 as shown,

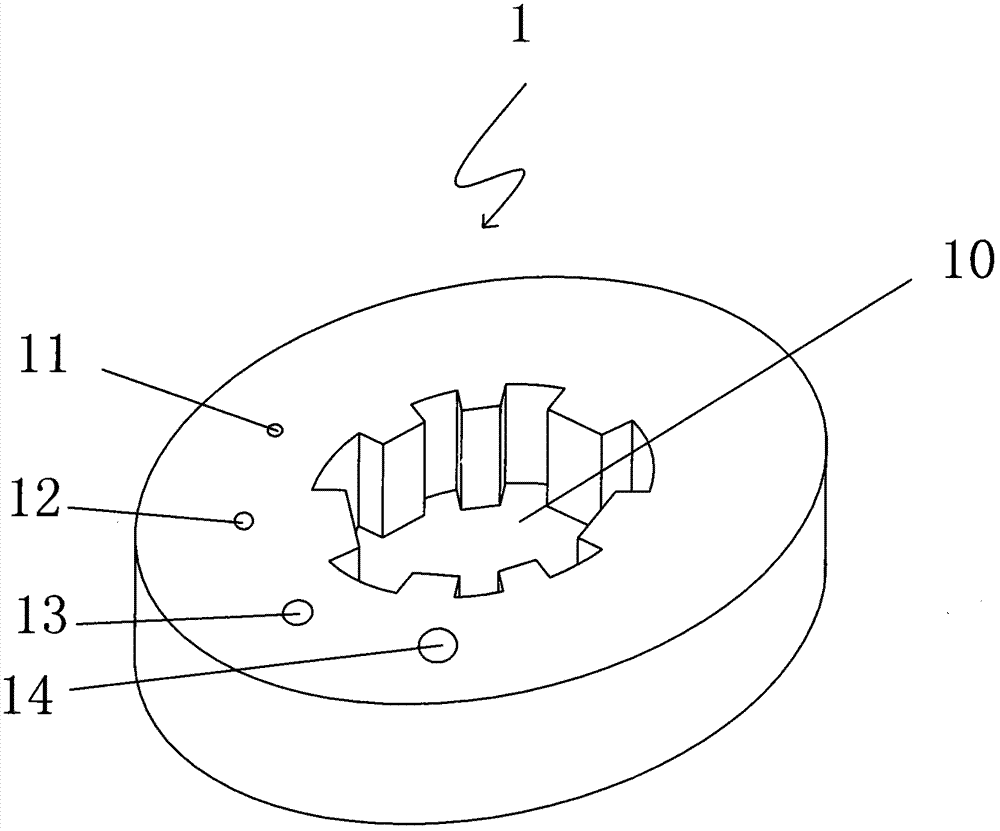

[0030] At first, obtain solid engine three-dimensional body data, the implementation image data of the present invention originates from the solid engine model workpiece 1 that contains artificial design defect (such as figure 2 As shown), the diameter of the workpiece 1 is 120mm, the shell steel wall thickness is 2mm, the center is the star hole 10 for filling medicine, and there are four unevenly distributed holes 11, 12, 13, 14 on the wall to represent defects, and the largest hole is 14 The diameter is 3mm, the smallest hole is 11 and the diameter is 2mm. The projection data is collected by the flat cone beam CT experimental system. The working process is as follows: First, the workpiece to be measured is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com