Dental compositions comprising addition-fragmentation agents

A technology of composition and breaking agent, which is applied in dentistry, dental prosthesis, dental preparations, etc., and can solve problems such as interface failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

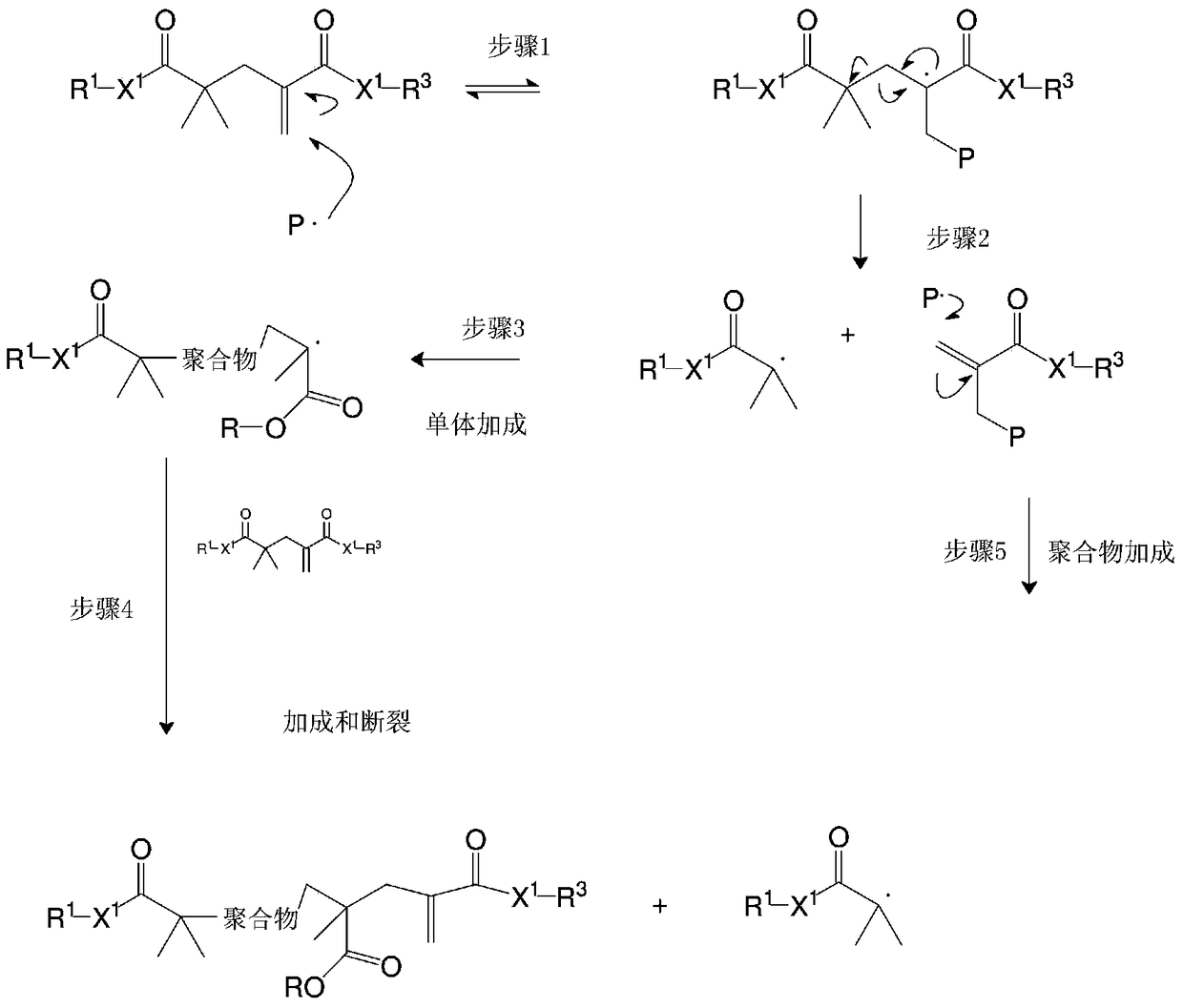

Method used

Image

Examples

example 1

[0279] Example 1 – AFL-1

[0280]

[0281] A 40 mL amber bottle was filled with diol 1 (7.500 g, 28.82 mmol) and 3-isocyanatopropyltriethoxysilane (14.255 g, 57.63 mmol). A magnetic stir bar was added to the bottle. With stirring, dibutyltin dilaurate (2 drops, from the tip of a glass pipette) was added and the reaction was sealed with a Teflon-lined plastic cap. After 3 days, the reaction was sampled, and 1 H NMR analysis was consistent with the expected product AFL-1. AFL-1 (21.73 g, 28.79 mmol, 99.9%) was obtained as a colorless, clear viscous material.

example 2

[0282] Example 2 – AFL-2

[0283]

[0284] A 40 mL amber bottle was filled with diol 2 (10.00 g, 21.16 mmol) and 3-isocyanatopropyltriethoxysilane (10.47 g, 42.33 mmol). A magnetic stir bar was added to the bottle. With stirring, dibutyltin dilaurate (2 drops, from the tip of a glass pipette) was added and the reaction was sealed with a Teflon-lined plastic cap. The reaction mixture was heated to 50°C with stirring. After 2 days, the reaction was cooled to room temperature and sampled. 1 H NMR analysis was consistent with the expected product AFL-2. AFL-2 (20.33 g, 21.02 mmol, 99.3%) was obtained as a very pale yellow clear viscous material.

example 3

[0285] Example 3 – AFL-3

[0286]

[0287] A solution was prepared by dissolving 2-mercaptoethanol (25.60 g, 0.328 mol) in 100 mL of ethanol in a 500 mL 2-necked round bottom flask equipped with a magnetic stir bar, condenser and dropping funnel. With vigorous stirring, small pieces of sodium metal (8.20 g, 0.356 mol) were added slowly to control the exotherm during the addition. After the addition of metallic sodium was complete, the mixture was stirred under a nitrogen blanket until the contents of the flask cooled to room temperature. A solution of 3-chloro-2-chloromethyl-1-propene ((20 g, 0.16 mol) in 50 mL of ethanol) was added dropwise using a dropping funnel to form a white cloudy mixture, followed by addition of all dichloropropene The components then formed a heterogeneous mixture with a white solid. The contents of the flask were refluxed for 45 minutes, then cooled to room temperature. The white solid was removed by vacuum filtration, and the filter cake was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap