Rotor for a permanent magnet electric machine and use thereof

A permanent magnet and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electromechanical devices, etc., can solve the problems of low efficiency, positioning torque and torque consistency, and achieve improved torque consistency, expensive and simple , The effect of small detent torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to be able to describe the exemplary embodiment concisely, identical elements are provided with the same reference numerals and only details relevant to the invention are explained in each case.

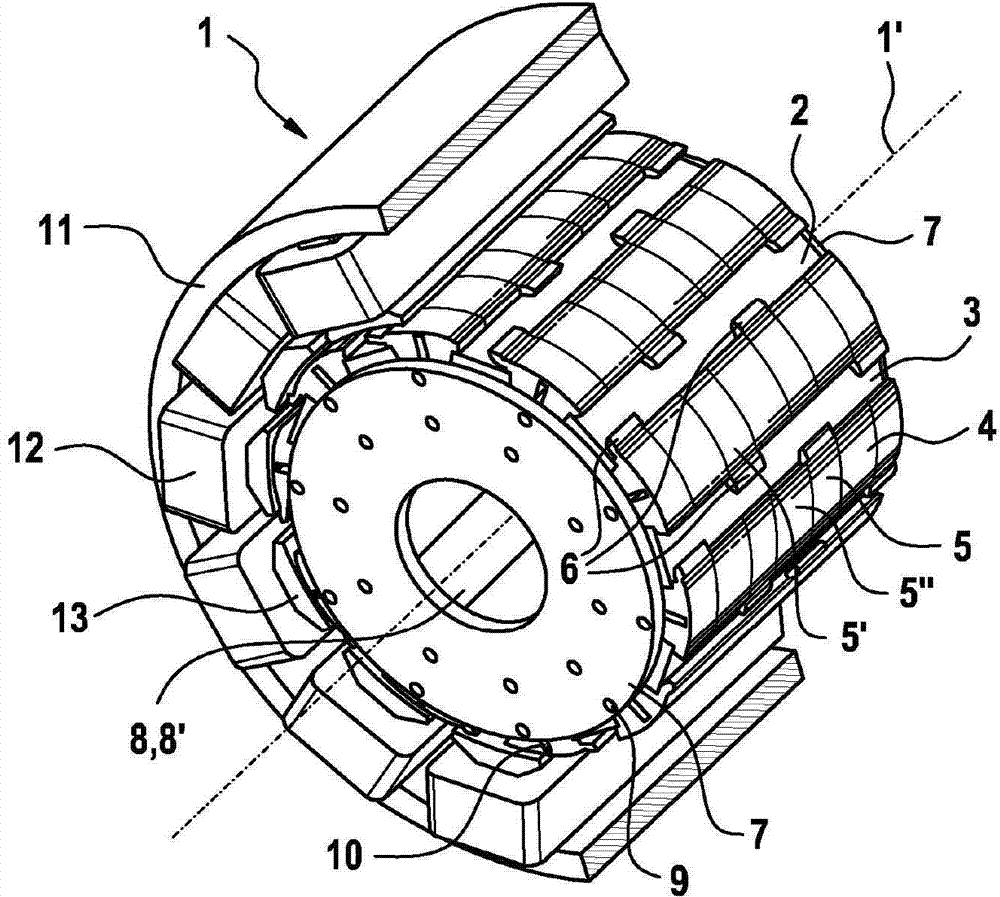

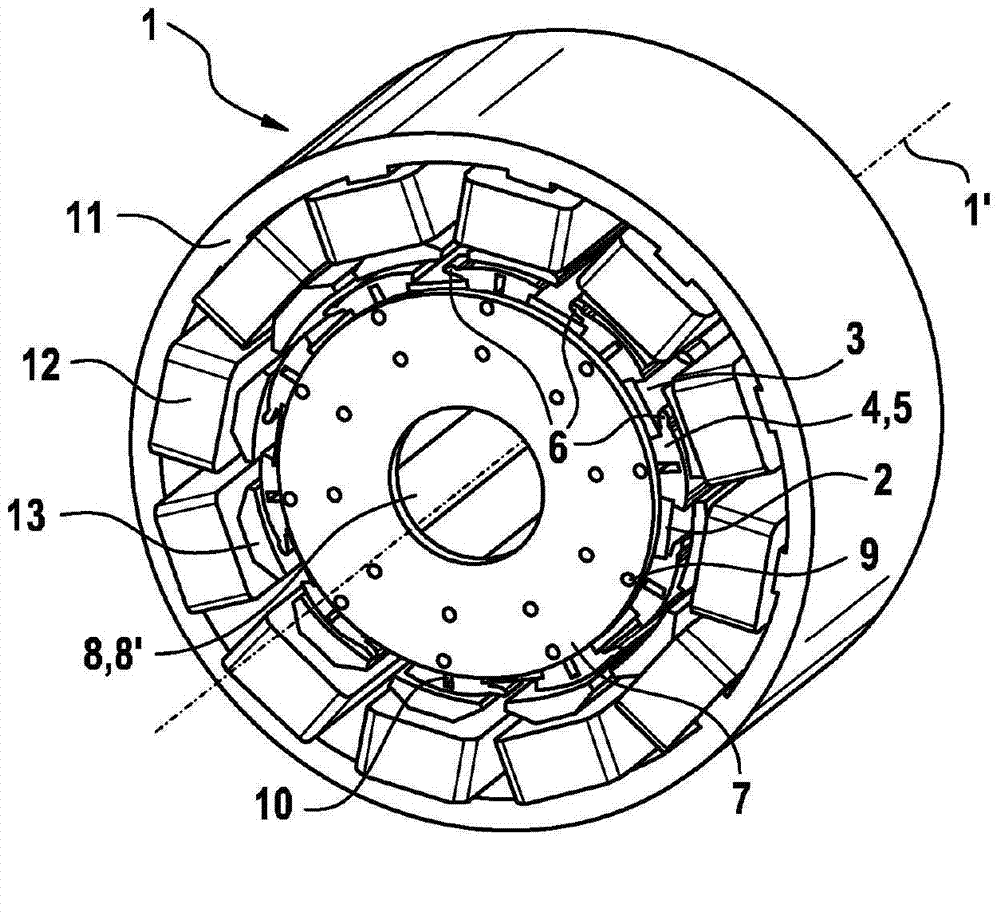

[0040] figure 1 Taking the electric motor 1 as an example, a perspective view of the electric motor 1 according to the invention is shown, limited to the essential components—the stator 11 and the rotor 2 , the stator 11 being drawn in section for illustration. figure 2 The electric motor 1 is likewise shown in a simplified perspective view, but not shown in section.

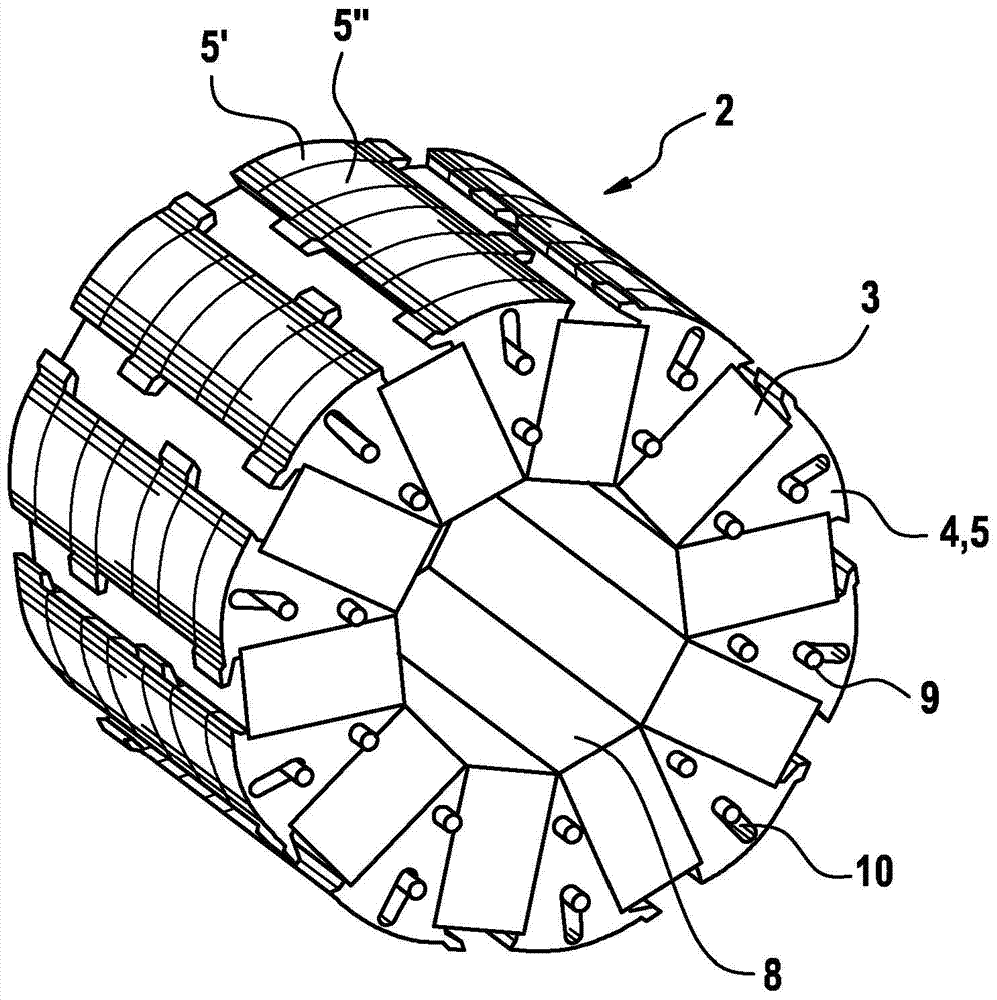

[0041] Field coils 12 are arranged on the pole shoes 13 of the stator 11 around the rotation of the rotor 2 and are electrically excited in a manner known per se to cause a rotation of the rotor by generating a rotating magnetic field. The rotor 2 comprises permanent magnets 3 and pole segments 4 which extend along the rotor axis and are arranged coaxially around the rotor axis 1 ′, alternating circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com