Positioning structure and method of in-mould injection molding steel sheet

A technology of positioning structure and in-mold injection molding, applied in the direction of coating, can solve the problems of poor production, thin wall thickness, warping of injection molding steel sheets, etc., and achieve the effect of preventing warping and deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

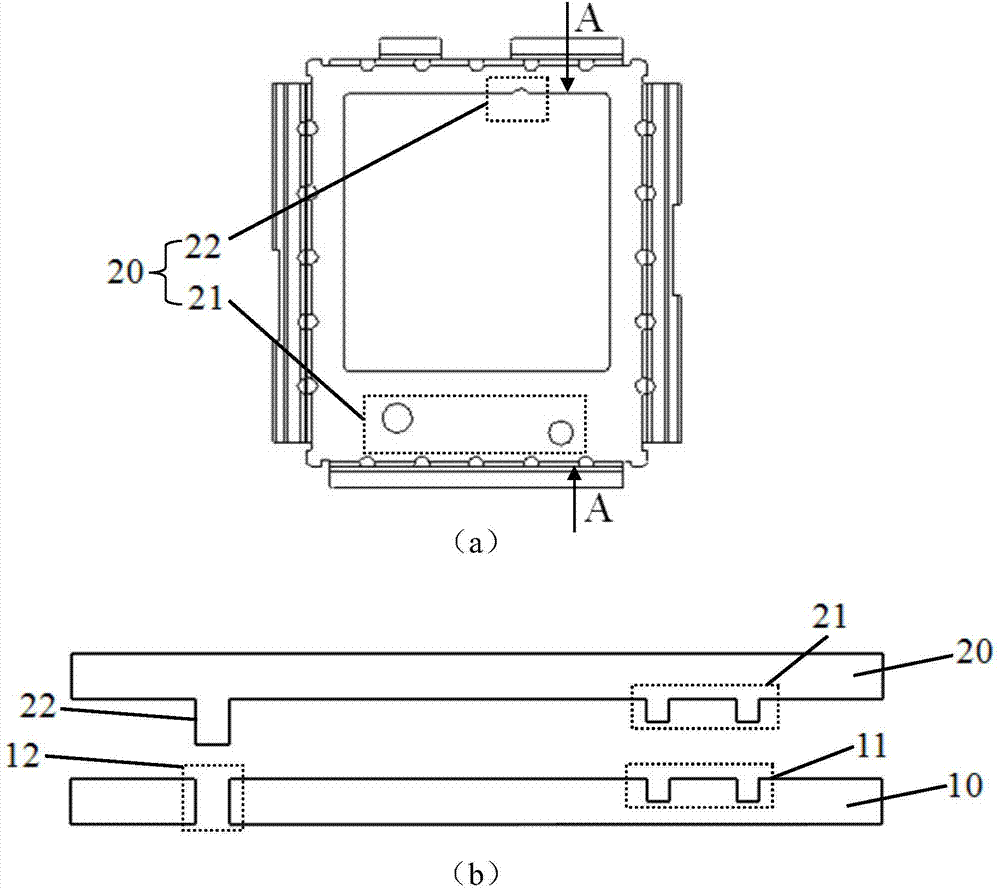

[0026] figure 1 It is a schematic diagram of the positioning structure of the in-mold injection-molded steel sheet according to Embodiment 1 of the present invention, (a) is a front view, and (b) is a schematic cross-sectional view of Figure (a) in the direction A-A.

[0027] refer to figure 1 In (a), (b), the positioning structure of the in-mold injection-molded steel sheet according to Embodiment 1 of the present invention includes: a steel sheet 10 and a mold 20 for positioning the steel sheet 10, wherein the steel sheet 10 is included in the steel sheet The first positioning hole 11 and the second positioning hole 12 in the direction perpendicular to the steel sheet 10 are respectively provided at both ends of the Y direction of the sheet, that is, the first positioning hole 11 and the second positioning hole 12 penetrate through the steel sheet 10. Z direction; the mold 20 includes a first positioning piece 21 and a second positioning piece 22 matched with the first posi...

Embodiment 2

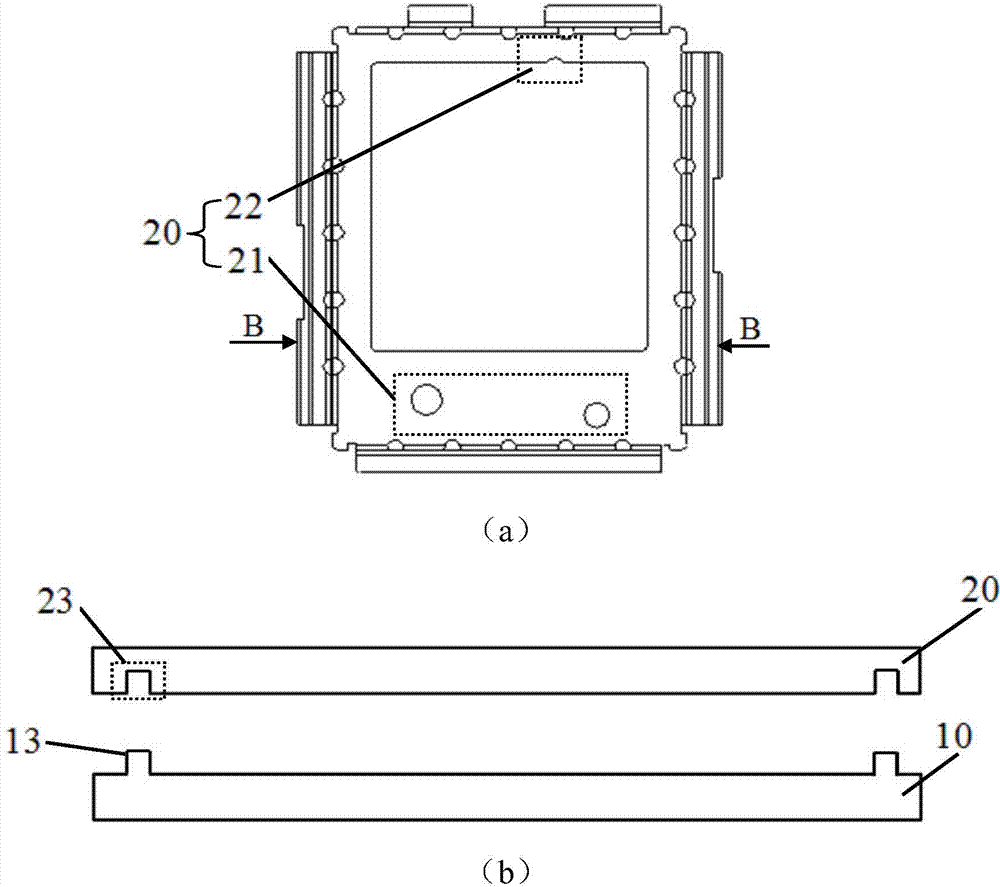

[0036] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 2 and embodiment 1 is that, referring to image 3 , where (a) is the main view, and (b) is a schematic cross-sectional view of Figure (a) in the B-B direction; the steel sheet 10 also includes clips 13 extending toward both ends in the X direction, and correspondingly, the mold 20 also includes for Corresponding to the card slot 23 of the card member 13; wherein, since the figure (a) is a view from the top view, the card member 13 and the card slot 23 cannot be seen.

[0037] Specifically, the clip 13 is a protrusion facing the Z direction of the steel sheet 10, so that the protruding clip 13 can be correspondingly clamped in the slot 23, so that the slot 23 firmly "bites" the clip 13. live" to prevent the steel sheet 10 from being deflected in the X direction.

[0038] Corresp...

Embodiment 3

[0042] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. combine figure 1 The schematic diagram of the positioning structure of the injection-molded steel sheet in the mold, the difference between embodiment 3 and embodiment 1 is that the mold 20 also includes positioning columns 24 that are clamped at both ends of the steel sheet 10 in the Y direction and point to the Z direction, as Figure 5 shown.

[0043] In the present embodiment, there are five positioning columns 24, including three positioning columns ( Figure 5 shown in the dotted line box), and the other end opposite to it is distributed with other two positioning columns (not shown in the figure).

[0044] Correspondingly, Image 6 It is a flow chart of the steps of the positioning method for the in-mold injection-molded steel sheet according to Embodiment 3 of the present invention.

[0045] refer to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap