An extruder screw with internal and external spirals

A technology of internal and external threads and screws, applied in the field of extrusion machinery, can solve the problems of slow material conveying speed, long material residence time, and low back pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

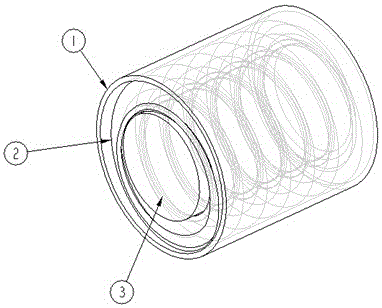

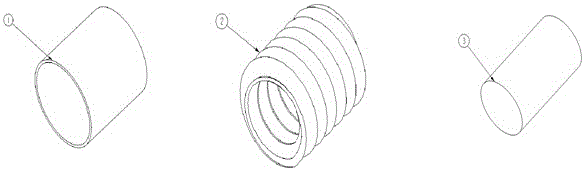

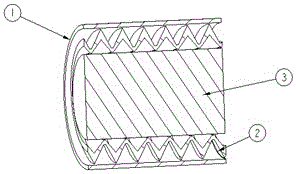

[0013] Embodiment 1: The present invention includes a barrel 1, a screw 2 with internal and external threads, and a central shaft 3. The mutual cooperation of the three can greatly improve the extrusion efficiency and increase the production capacity ratio. The screw rod 2 is hollow and has both internal and external threads. The helical directions of the internal and external threads of the screw rod 2 are the same. The screw 2 forms an outer runner and an inner runner with the barrel 1 and the central shaft 3 respectively. The shapes of the internal and external threads of the screw 2 are different, so that the pressure building capacity of the internal and external channels is the same, and the external flow channel is formed between the screw 2 and the barrel 1, which is the same as that of an ordinary single-screw extruder. An inner runner is formed between the screw 2 and the central shaft 3, and the extrusion efficiency per unit time of the extruder is improved through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com