Full-automatic box folding machine of semi-packed box of heat collector

A folding box machine and heat collector technology, applied in carton/carton manufacturing machinery, containers, packaging, etc., can solve the problems of uneven quality, high labor intensity and high labor cost, reduce management costs, and facilitate workers. Operation, ensuring the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is the best example of the full-automatic box folding machine for half-packed boxes of heat collectors in the present invention, and does not limit the scope of protection of the present invention.

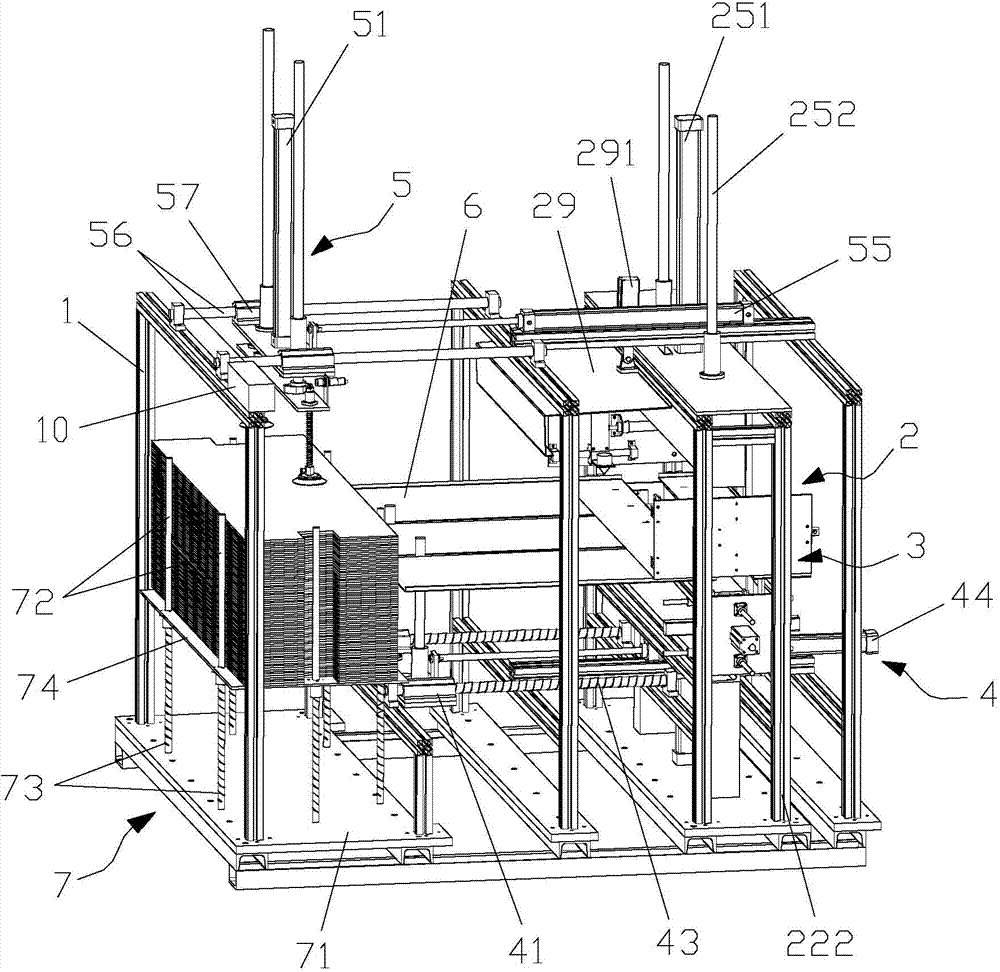

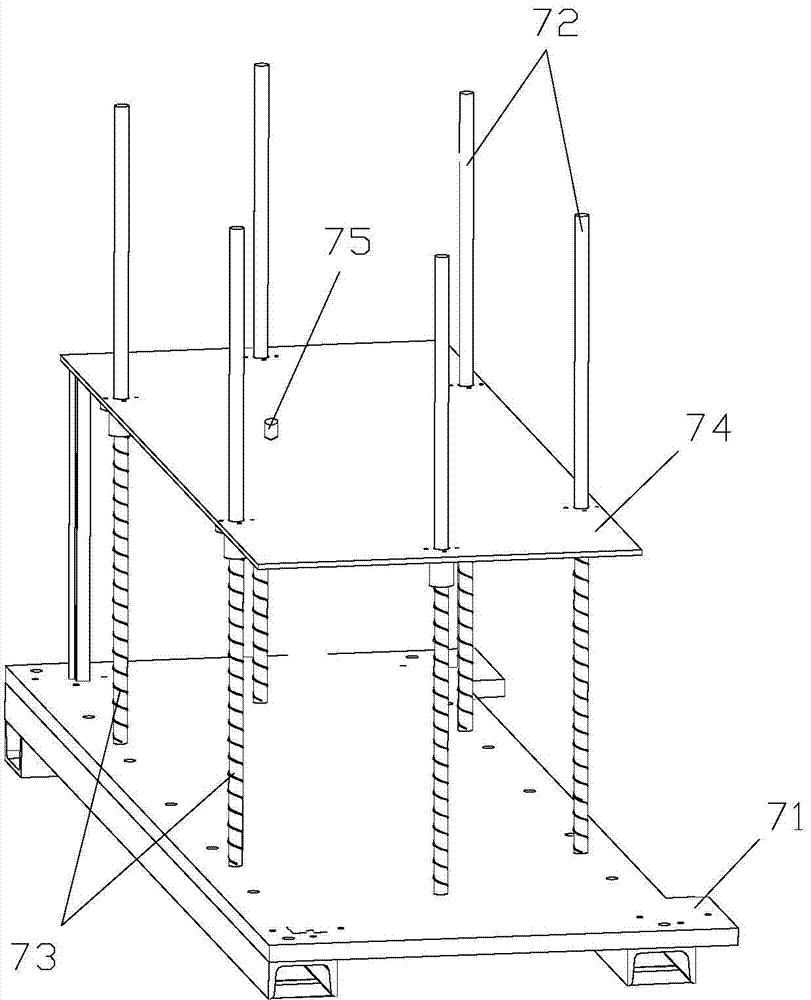

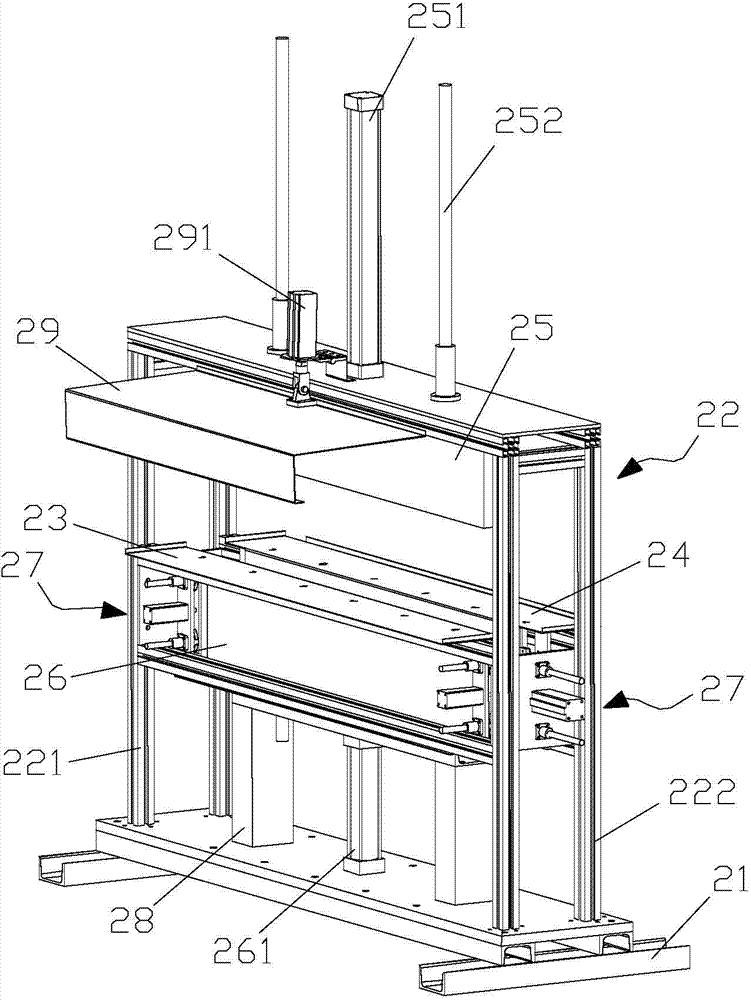

[0023] Please refer to figure 1 , the figure shows a kind of heat collector semi-pack full-automatic box folding machine, including frame 1, and the bottom of frame 1 is provided with folding box mechanism 2, and the both sides of this folding box mechanism 2 are equipped with The gluing mechanism 3 is provided with a positioning mechanism 4 below the folding box mechanism 2, and the grasping and shifting mechanism 5 is arranged on the frame 1, and a feeding connecting plate 6 is also included, and the feeding connecting plate 6 is close to the folding box Mechanism 2, the bottom of the frame 1 is also equipped with a box plate limiting mechanism 7, when starting, the grasping and shifting mechanism 5 can grab the carton plate from the box plate limiting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com