Horse hoof base locking face orientating grain arranger

A pelletizer and horse foot-based technology, which is applied in the field of horsefoot-lock face recognition pelletizers, can solve the problems of low efficiency in the direction of pellet discharge, and achieve the effect of improving accuracy and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

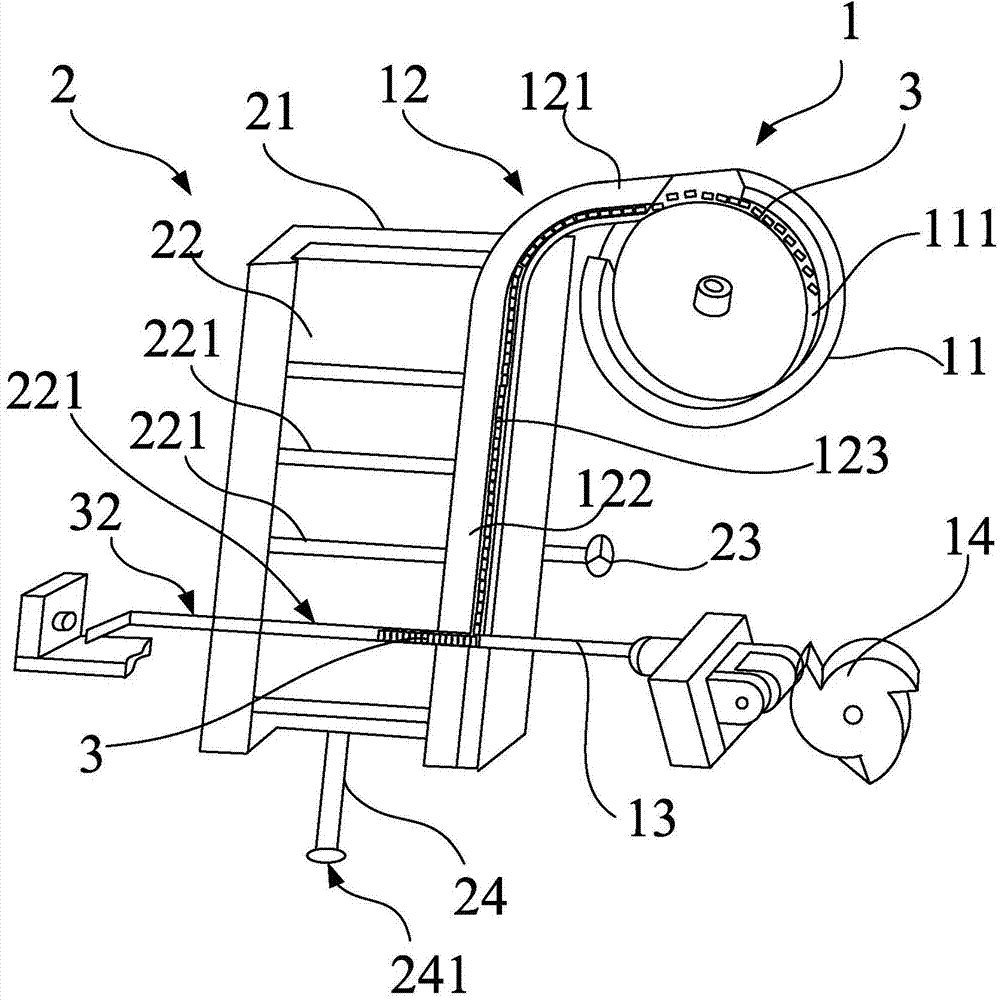

[0030] The purpose of the present invention is achieved through the following technical solutions: as Figure 1 ~ Figure 3 As shown, the horse foot base lock surface recognition granulator provided in this embodiment includes an operating table (not shown in the figure), on which is provided: a set for processing product particles (i.e. precious stones) Bearing particles 3) a directional granulation unit 2 for directional granulation, and an oscillating conveying unit 1 for transporting the jewel bearing granules 3 to be processed to the directional granulation unit along the same length direction.

[0031] Another example figure 1 As shown, the oscillating conveying unit 1 includes: an oscillating plate 11, a feeding guide rail 12 and a thimble 13 for intermittent thrusting motion, wherein the oscillating plate near the flange of the oscillating plate 11 A guide groove 111 for feeding is formed on the disk surface; and a row of grain grooves 123 is formed along the length di...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that in this embodiment, if figure 1 As shown, the bottom of the directional particle discharge plate 22 is also connected with a pull rod 24 for dragging the directional particle discharge plate, so as to remove the full directional particle discharge plate from the bottom plate 21 conveniently. For ease of handling, the outwardly drawn rod end of the pull rod 24 is provided with a round end 241 .

[0049] Other parts of this embodiment are identical to Embodiment 1.

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that, in this embodiment, a bar is provided on the surface of the oscillating disk close to its guide groove, which is used to guide the jewel bearing particles to gather near the guide groove more quickly, And it is more convenient to input along the guide groove.

[0052] Other parts of this embodiment are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com