Jewel bearing workpiece and mounting method thereof

A gem bearing and installation method technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of fragile gem bearings, clumsy installation methods, poor concentricity and parallelism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

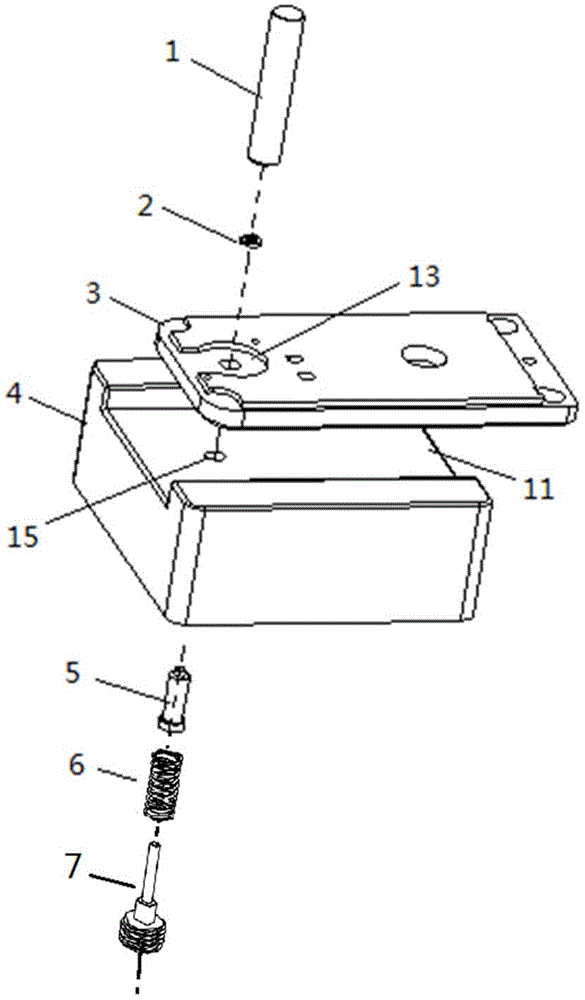

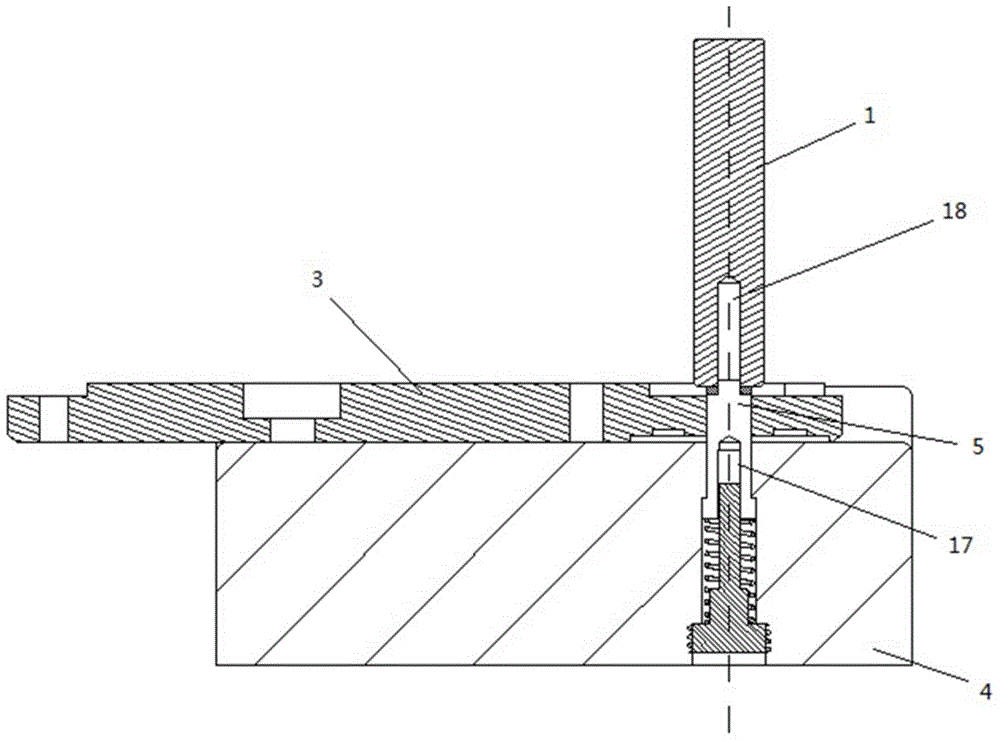

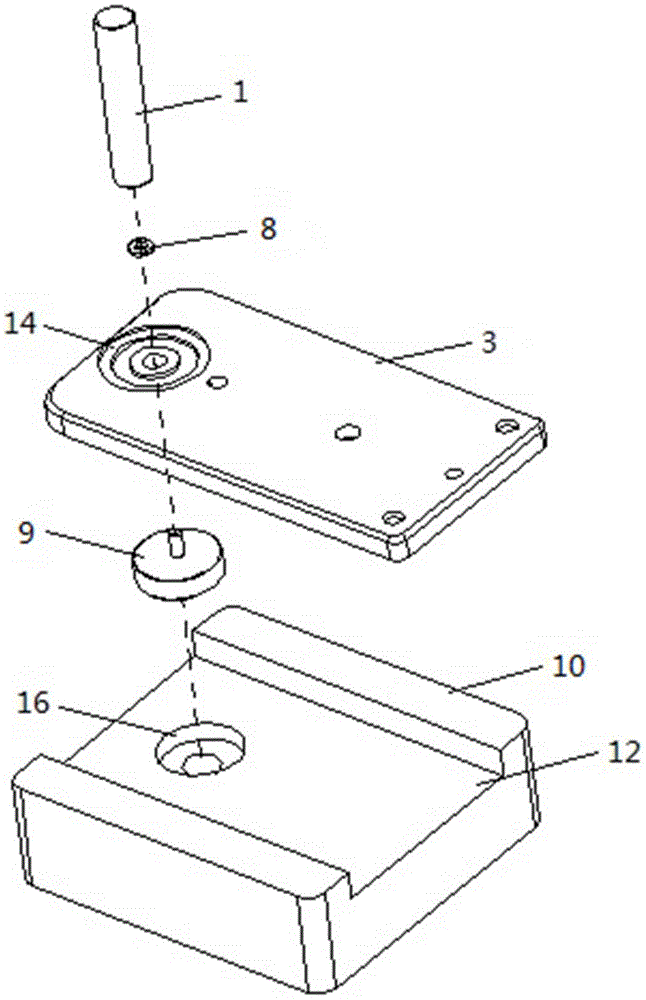

[0026] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0027] The invention discloses a jewel bearing workpiece and an installation method thereof. The tools needed to install the first jewel bearing 2 are as follows: figure 1 As shown, the order of arrangement from top to bottom is: upper mounting handle 1, first jewel bearing 2, jewel bearing workpiece 3, first base 4, lower mounting handle 5, return spring 6 and guide shaft 7; The mounting handle has a mounting handle hole-like structure 17, the guide shaft is set in the lower mounting handle hole-like structure, and the back-moving spring is sleeved on the guide shaft, and is installed between the lower mounting handle and the guide shaft. Similarly, the upper mounting handle also has an upper mounting handle hole-like structure 18 for cooperating with the lower mounting handle to exert pressure on the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com