Method for controlling glass to be heated in glass toughening process

A glass tempering and glass heating technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems that affect product qualification rate, quality stability, thickness error, and heating time calculation so accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

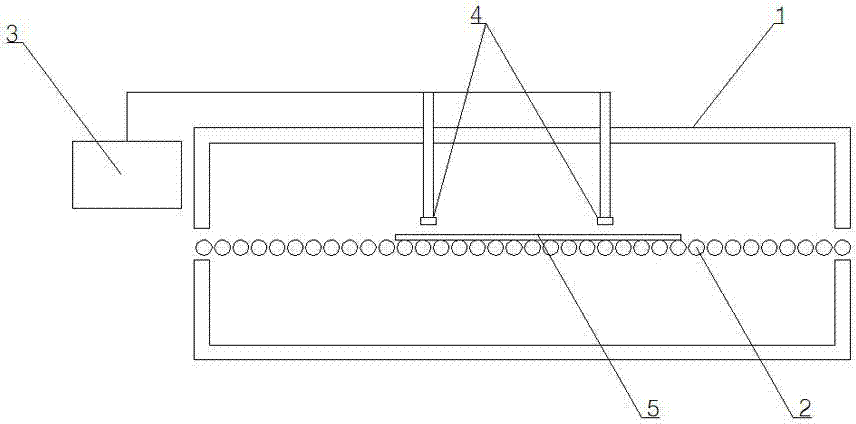

[0017] Such as figure 1 Shown: a method for controlling the heating section in the glass tempering process. Two temperature sensors 4 for detecting the temperature of the glass in the heating section 1 are installed in the heating section 1 of the glass tempering furnace. The two temperature sensors 4 are thermocouple temperature Sensors, two temperature sensors 4 are arranged above the transmission roller table 2, the temperature sensor 4 is connected with the control center 3 of the glass tempering furnace, and the control center 3 is also connected with the transmission mechanism controller of the heating section 1, before the glass is heated, According to the different glass to be tempered, the temperature to be heated to or close to the glass in the heating section 1 is set in advance. When the glass is in the heating process, when the temperature sensor 4 detects that the temperature of the glass reaches or is close to the set temperature, the control center 3 sends an i...

Embodiment 2

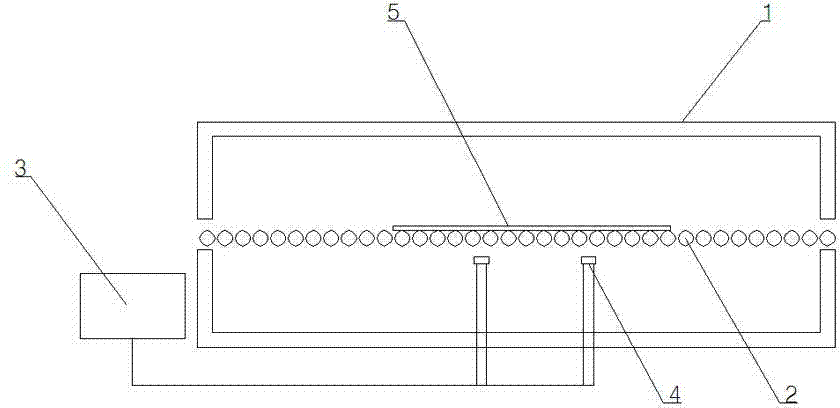

[0020] Such as figure 2 Shown: a control method for the heating section in the glass tempering process, two temperature sensors 4 for detecting the temperature of the glass in the heating section 1 are arranged in the heating section 1 of the glass tempering furnace, and the two temperature sensors 4 are thermal resistance temperature Sensors, two temperature sensors 4 are arranged below the transmission roller table 2, the temperature sensors 4 are connected with the control center 3 of the glass tempering furnace, and the control center 3 is also connected with the transmission mechanism controller of the heating section 1, before the glass is heated, According to the different glass to be tempered, the temperature to be heated to or close to the glass in the heating section 1 is set in advance. When the glass is in the heating process, when the temperature sensor 4 detects that the temperature of the glass reaches or is close to the set temperature, the control center 3 sen...

Embodiment 3

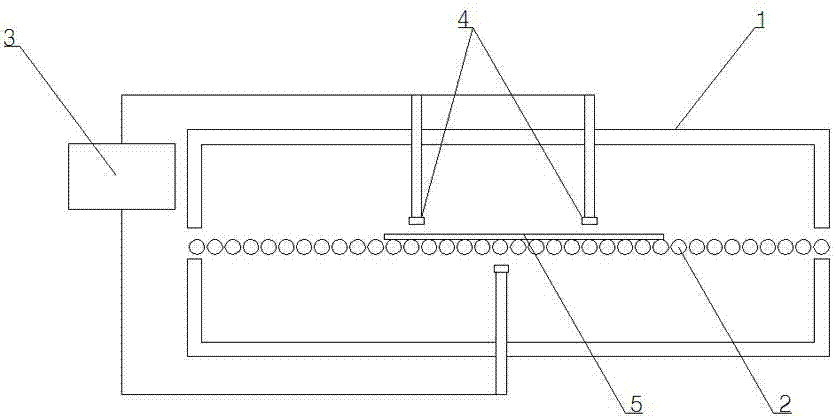

[0023] Such as image 3 Shown: a method for controlling the heating section in the glass tempering process. Three temperature sensors 4 for detecting the temperature of the glass in the heating section 1 are installed in the heating section 1 of the glass tempering furnace, and the three temperature sensors 4 are infrared temperature sensors. , wherein two temperature sensors 4 are arranged above the transmission roller table 2, and the other temperature sensor 4 is arranged below the transmission roller table 2, the temperature sensor 4 is connected with the control center 3 of the glass tempering furnace, and the control center 3 is also connected with the heating The transmission mechanism controller of section 1 is connected. Before the glass is heated, the temperature that the glass in heating section 1 needs to be heated to or close to is set in advance according to the different glass to be tempered. When the glass is heating, the temperature sensor 4 detects the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com