Pit slot three-dimensional index extracting and calculating method based on 3D line laser equipment

A calculation method, line laser technology, applied in the direction of using optical devices, measuring devices, instruments, etc., to achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention are described in further detail below:

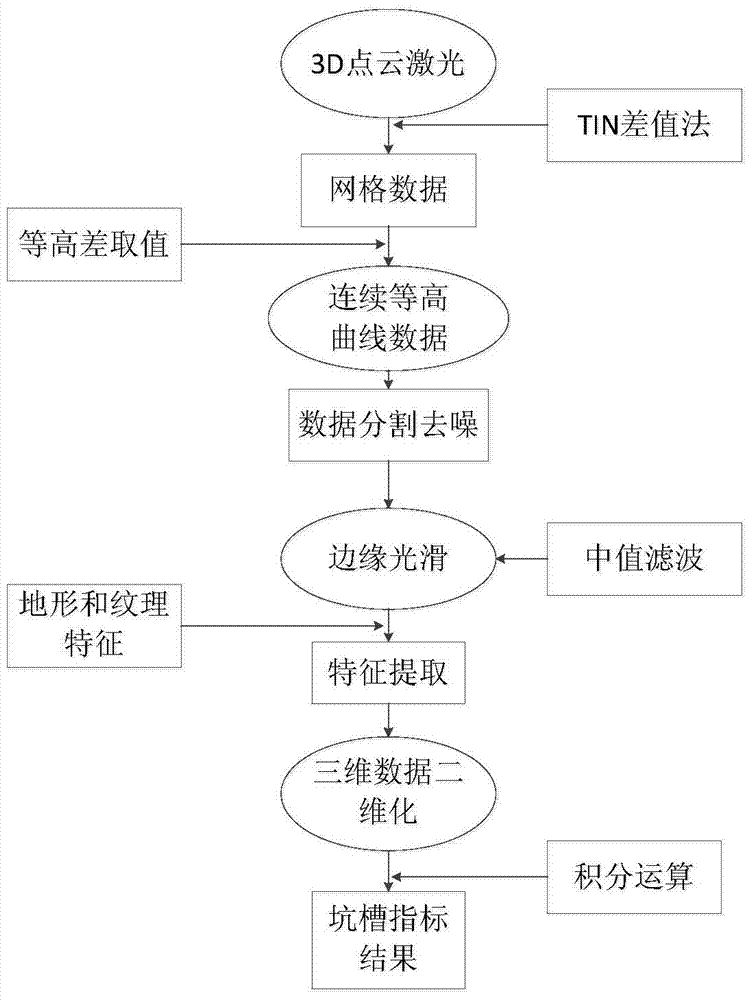

[0045] A calculation method for extracting and calculating a three-dimensional index of a pit based on a 3D line laser device, comprising the following steps:

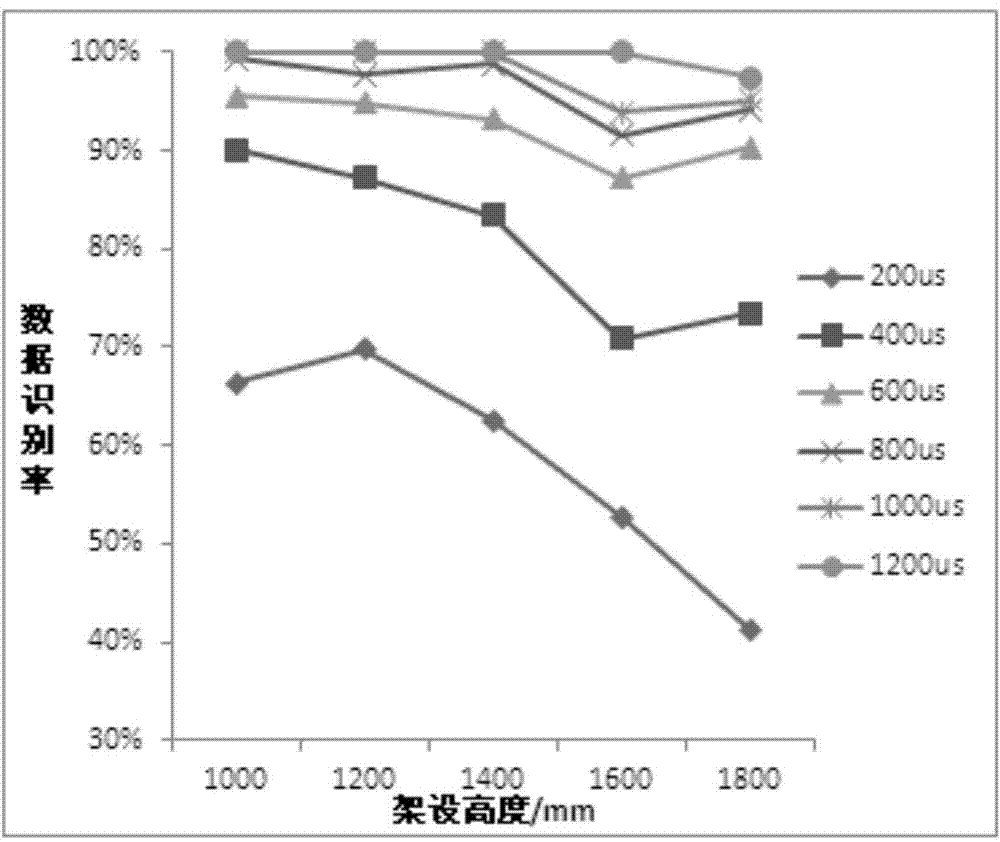

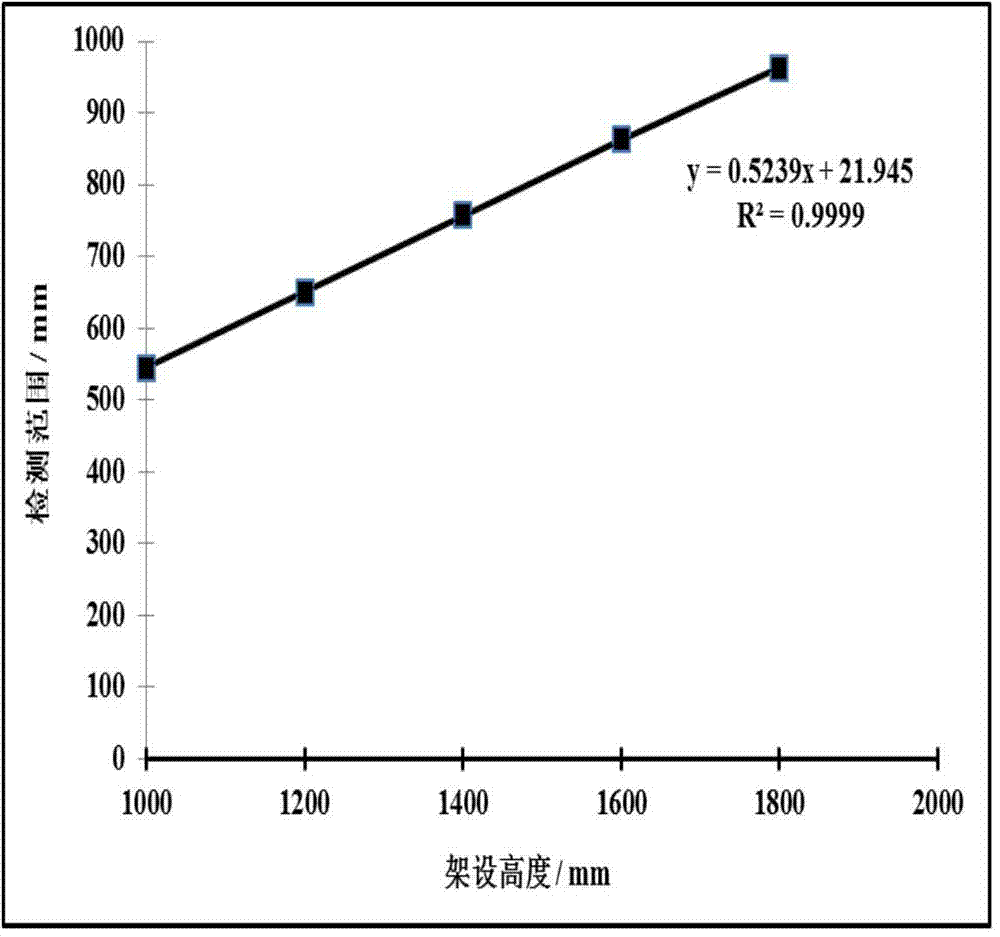

[0046] Step 1: Make 3 regular simulated pits with different depths and different areas. The simulated pits are a regular bowl-shaped pit disposed in the rut plate. The parameters affecting the recognition rate of 3D line laser equipment (setup height and exposure value) to calibrate to get the best combination of parameters;

[0047] Step 1.1: Carry out a single factor test on the parameters affecting the recognition rate of 3D line laser equipment;

[0048] Step 1.2: Analyze the results of the single factor test to obtain the optimal parameter combination.

[0049] Step 2: Identify and calculate pit depth, area and volume indicators under the optimal parameter combination calibrated in step 1; the specific operation steps are:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com