Epoxy resin composition, its cured product and light emitting diode

A technology of epoxy resin and composition, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of easy damage to colorless transparency, etc., and achieve excellent heat resistance and coloring, increased viscosity increase speed, and operability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0175] 79.0 parts by mass of H-TMAn [manufactured by Mitsubishi Gas Chemical Co., Ltd.], 21.0 parts by mass of a mixture of hexahydrophthalic anhydride and methylhexahydrophthalic anhydride [manufactured by Shin Nippon Chemical Co., Ltd. MH700G], alicyclic Formula epoxy resin compound [3,4-epoxycyclohexenylmethyl-3',4'-epoxycyclohexene carboxylate: CEL2021P manufactured by Daicel Corporation] 172 parts by mass, as glycidyl ester type epoxy Resin compound diglycidyl hexahydrophthalate [SR-HHPA manufactured by Sakamoto Pharmaceutical Co., Ltd.] 73.9 parts by mass, hindered phenolic antioxidant AO-50 (manufactured by ADEKA Corporation) 2.8 parts by mass, and quaternary phosphonium 0.80 parts by mass of bromine salt "U-CAT5003" manufactured by San-Apro Ltd. was mixed to obtain an epoxy resin composition. The physical property measurement and evaluation of the obtained epoxy resin composition and its hardened|cured material were performed by the method mentioned above. The results...

Embodiment 2~16 and comparative example 1~9

[0177]Except having changed the kind and ratio of a raw material component as shown in Tables 1-3, it carried out similarly to Example 1, and obtained the epoxy resin composition. The physical property measurement and evaluation of the obtained epoxy resin composition and its hardened|cured material were performed by the method mentioned above. The results are shown in Tables 1-3.

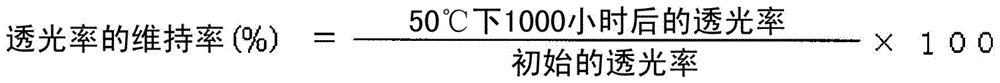

[0178] [Table 1]

[0179]

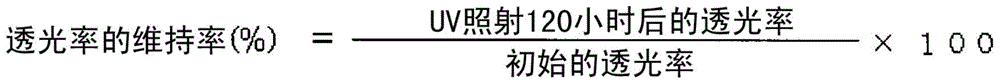

[0180] [Table 2]

[0181]

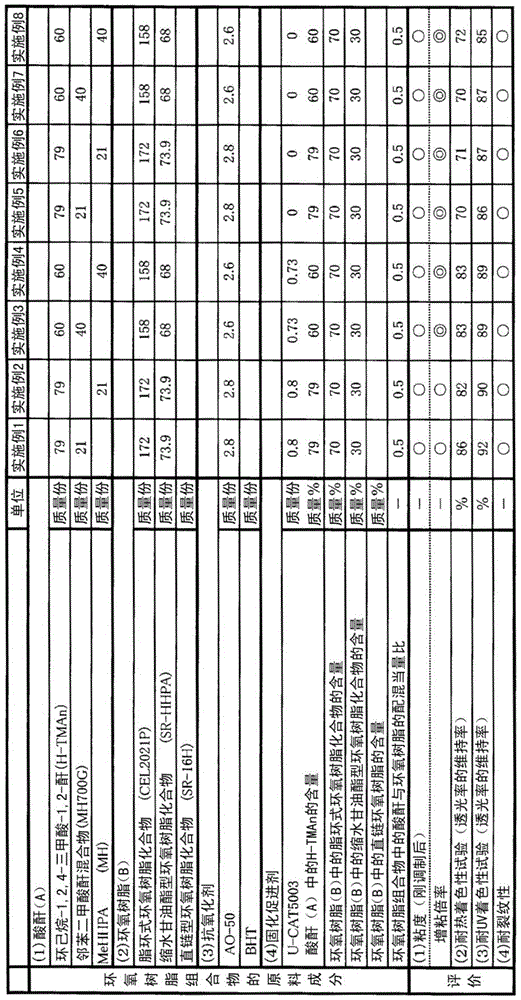

[0182] [table 3]

[0183]

[0184] From the above-mentioned Tables 1 to 3, the following matters can be understood.

[0185] It can be seen that for containing acid anhydride (A) and epoxy resin (B), and acid anhydride (A) contains cyclohexane-1,2,4-tricarboxylic acid-1,2-anhydride 30 to 90% by mass, epoxy resin ( B) An epoxy resin composition containing 30 to 90% by mass of an alicyclic epoxy resin compound, a glycidyl ester type epoxy resin compound, and a compounding equivalent ratio of an acid anhydride to an epoxy resin in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com