Radiation detection device and manufacturing method therefor

A radiation detection and radiation technology, applied in the field of radiation detection devices, can solve problems such as uneven lighting, narrowing of space, and clear shooting obstacles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

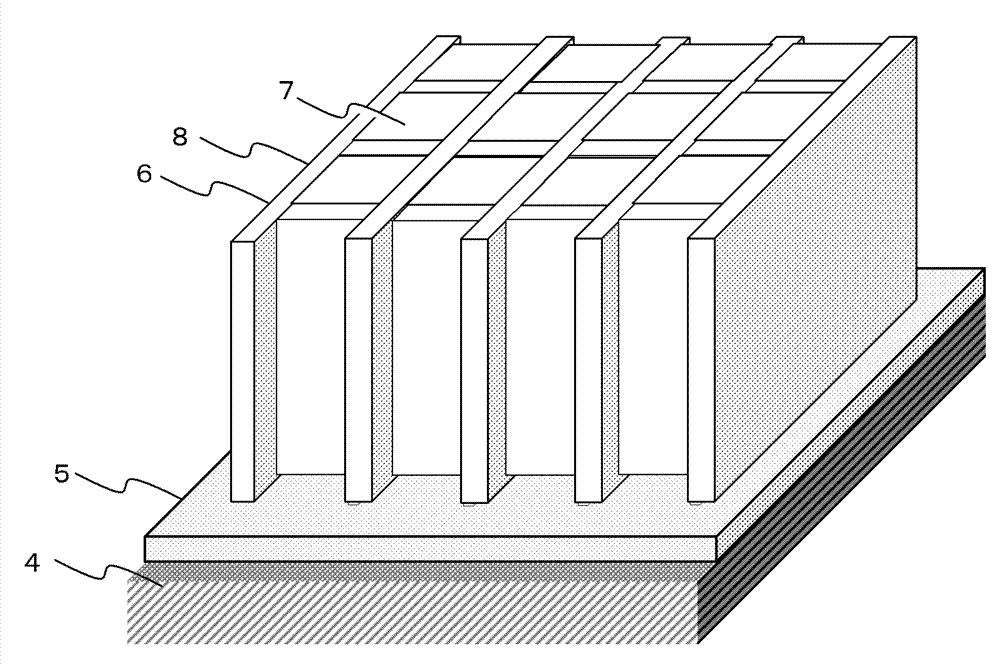

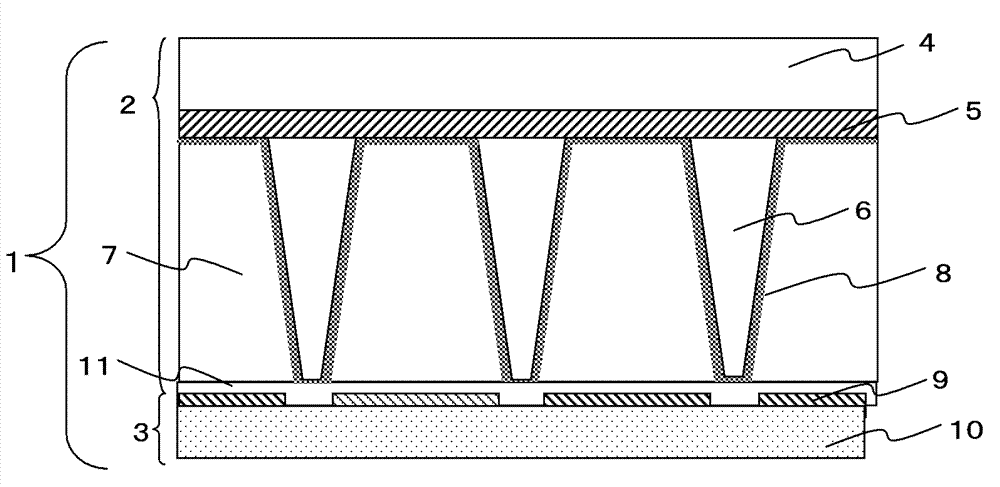

Embodiment 1)

[0132] On a glass substrate of 500 mm x 500 mm ("OA-10" manufactured by NEC Glass Co., Ltd.), apply a photosensitive paste for partition walls by die coating so that the dry thickness is 500 μm, and dry to form a photosensitive paste for partition walls. Apply film. Next, through a photomask (a chromium mask having grid-shaped openings with a pitch of 125 μm and a line width of 10 μm) formed with openings corresponding to a desired partition pattern, a 700 mJ / cm 2 The photosensitive paste coating film for partition walls was exposed to the exposure amount of . The photosensitive paste coating film for partition walls after exposure was developed in 0.5 mass % of ethanolamine aqueous solution, the unexposed part was removed, and the photosensitive paste coating film pattern of grid shape was formed. Furthermore, the photosensitive paste coating film pattern was sintered in the air at 585° C. for 15 minutes, and the interval L2 with partition walls formed on the surface was 125...

Embodiment 2)

[0138] A substrate on which lattice-shaped partition walls were formed was produced by the same method as in Example 1. Thereafter, an aluminum film, that is, a reflective film, was formed on the surface of the partition wall and the surface of the substrate where the partition wall was not formed by a intermittent sputtering device ("SV-9045" manufactured by ULVAC). The formed aluminum film had a thickness of 300 nm at the top of the partition wall, a thickness of 100 nm of the aluminum film on the side of the partition wall, and a thickness of 100 nm of the aluminum film on the substrate.

[0139] Next, after mixing gadolinium oxysulfide powder with a particle size of 5 μm and a refractive index of 2.2 as a phosphor with ethyl cellulose with a refractive index of 1.5, it is filled in the space defined by the partition wall to produce a phosphor in the cell. Scintillator panels with a volume fraction of 90%. Using the produced scintillator panel, by the same method as in Exa...

Embodiment 3)

[0141] Except having changed the glass substrate of Example 1 into the tungsten substrate (made by Applied Materials) of 300x300 mm, the radiation detection apparatus was produced and evaluated by the method similar to Example 1. As a result, the X-rays transmitted through the radiation detection device are absorbed by the tungsten substrate, so the noise is reduced, and the brightness is 110 and the resolution is 165, both of which are good values.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com